The encoder costs around 150 Euro including the scale.....

Affordable to some - not so affordable to others.

Affordable to some - not so affordable to others.

(See y'all -- I'll have to read the rest in the transcripts)

(See y'all -- I'll have to read the rest in the transcripts)

yeah.....more flexiblity for research institutes....

yeah.....more flexiblity for research institutes....

![]() how large a max displacement can those measure?

how large a max displacement can those measure?

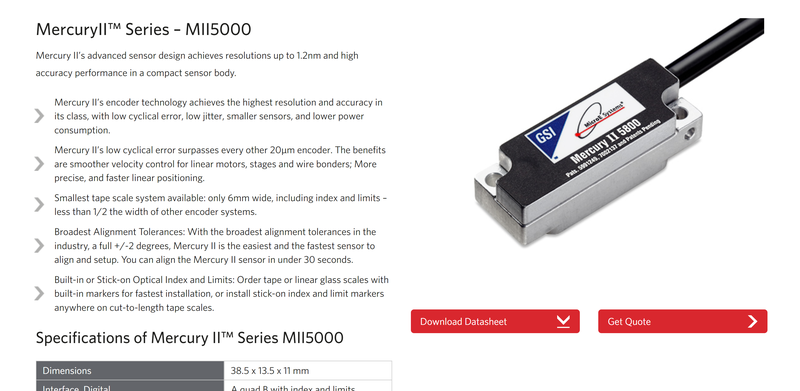

![]() Which series encoder did you use? The accuracy seems to be "+/- 1um"

Which series encoder did you use? The accuracy seems to be "+/- 1um"

![]() ... oh per meter?

... oh per meter?

The encoder has two different types of scale: glass, metal tape. The metal tape can go meters

The encoder has two different types of scale: glass, metal tape. The metal tape can go meters

Let me check the model...because I use them 6 years ago...things chaged

Let me check the model...because I use them 6 years ago...things chaged

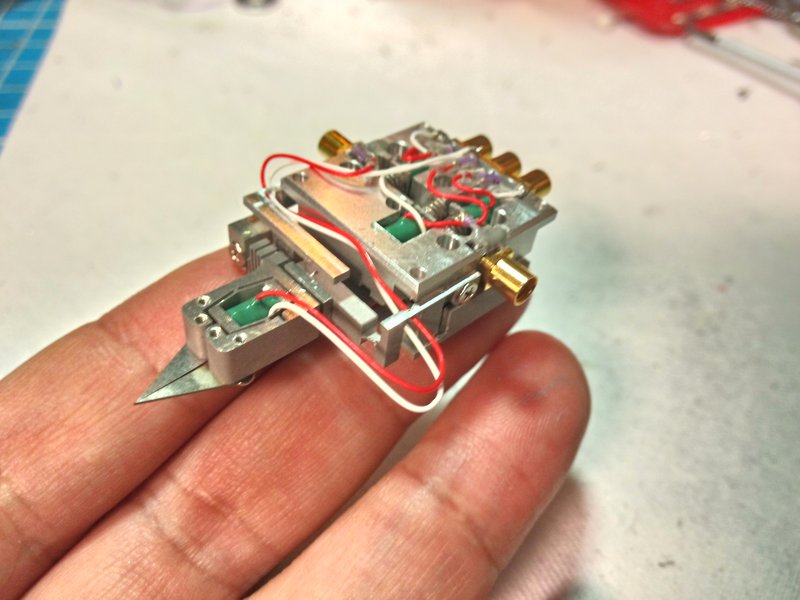

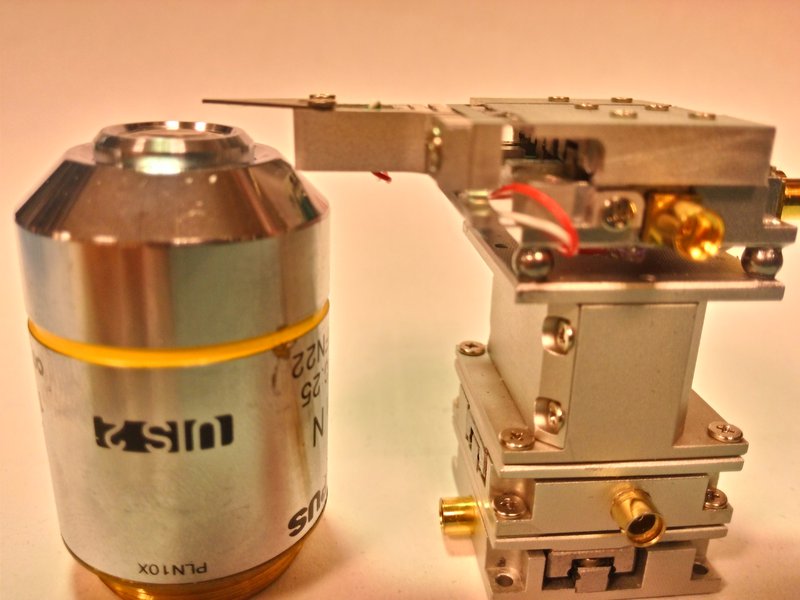

I built UHV STM, AFM and nano TXM before....I use my home made positioner for approaching and scanning

I built UHV STM, AFM and nano TXM before....I use my home made positioner for approaching and scanning

I seem to be unable to download a full text version of the u-LBIC conference contribution :/

I seem to be unable to download a full text version of the u-LBIC conference contribution :/

@Edwin Hwu I guess for the long travel range you demonstrated, encoders are the right choice. I thought about something with 0.5mm travel and 200nm repeatability or so... Do you have any experience with Hall sensors? Not sure if the resolution is high enough... But they are likely super cheap.

@Edwin Hwu I guess for the long travel range you demonstrated, encoders are the right choice. I thought about something with 0.5mm travel and 200nm repeatability or so... Do you have any experience with Hall sensors? Not sure if the resolution is high enough... But they are likely super cheap.

https://www.instructables.com/A-Low-Cost-Atomic-Force-Microscope-%E4%BD%8E%E6%88%90%E6%9C%AC%E5%8E%9F%E5%AD%90%E5%8A%9B%E9%A1%AF%E5%BE%AE%E9%8F%A1/ one of my hobby work

https://www.instructables.com/A-Low-Cost-Atomic-Force-Microscope-%E4%BD%8E%E6%88%90%E6%9C%AC%E5%8E%9F%E5%AD%90%E5%8A%9B%E9%A1%AF%E5%BE%AE%E9%8F%A1/ one of my hobby work

![]() Out of curiosity how are those metal tapes encoded?

Out of curiosity how are those metal tapes encoded?

I am not so familiar with the magnetic one...but my student told me that they are robust

I am not so familiar with the magnetic one...but my student told me that they are robust

Those metal tapes has microscale marks....so be careful not to touch them

Those metal tapes has microscale marks....so be careful not to touch them

![]() What is the best way to get in get in touch with you to collaborate on closed loop positioning?

What is the best way to get in get in touch with you to collaborate on closed loop positioning?

This is the one I am using

This is the one I am using

1.2 nm

1.2 nm

I am amazed at the positioning speed in your videos, were those using your open source controller?

I am amazed at the positioning speed in your videos, were those using your open source controller?

@placethesundontshine you can contact me by email: etehw@dtu.dk

@placethesundontshine you can contact me by email: etehw@dtu.dk

or my gmail: whoand@gmail.com

or my gmail: whoand@gmail.com

I also have some colleagues in DTU like to build one

I also have some colleagues in DTU like to build one

I really like to open source closed loop system, because it is more valuable and useful

I really like to open source closed loop system, because it is more valuable and useful

@polyfractal you are right, but if we use different mechanism for heavy weight

@polyfractal you are right, but if we use different mechanism for heavy weight

I built tip till also...let me find photo

I built tip till also...let me find photo

Have you explored the possibility of using photoelectric effect to fine-tune a piezo actuator's extension?

Have you explored the possibility of using photoelectric effect to fine-tune a piezo actuator's extension?

photoelectric effect? not yet touched ;P

photoelectric effect? not yet touched ;P

So are hard drive head positioners essentially "out of the box" nanopositioners? Or do they need some fine tuning?

So are hard drive head positioners essentially "out of the box" nanopositioners? Or do they need some fine tuning?

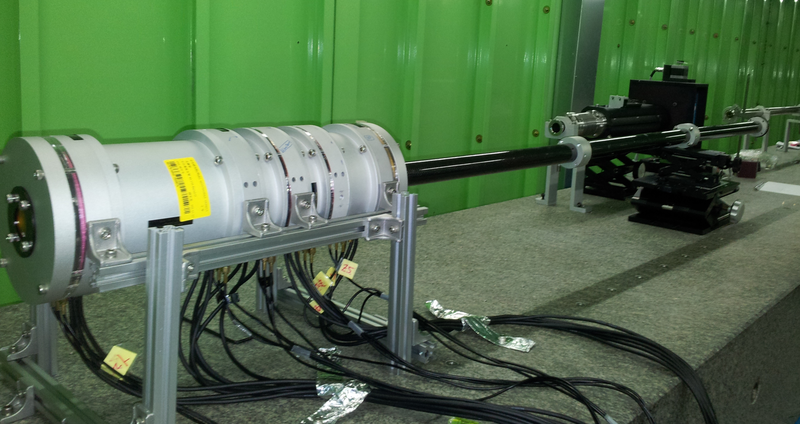

This 7 axes system was my fun work haha!

This 7 axes system was my fun work haha!

Yes, all flexture based rol/tip/til by 3 linear actuator

Yes, all flexture based rol/tip/til by 3 linear actuator

OIW, are the tracks nanoscale apart on a disk platter?

OIW, are the tracks nanoscale apart on a disk platter?

![]() yes they are

yes they are

@Dan Maloney you are right! the hard drive arm is super precise!

@Dan Maloney you are right! the hard drive arm is super precise!

Thanks! My bad habit was not to do proper testing then moved to next one...so the 7 axes system is not publishable...

Thanks! My bad habit was not to do proper testing then moved to next one...so the 7 axes system is not publishable...

Let me find the 7 axes sysetm video

Let me find the 7 axes sysetm video

I think hdd arms also have the superpower of higher bandwidth than a lot of "nano" scale actuators, no?

I think hdd arms also have the superpower of higher bandwidth than a lot of "nano" scale actuators, no?

Play Video

Play Video

![]() Would you be interested in open sourcing those 7 axis for others to chip at?

Would you be interested in open sourcing those 7 axis for others to chip at?

I dig those flexures!

I dig those flexures!

![]() I found this interesting: https://documents.westerndigital.com/content/dam/doc-library/en_us/assets/public/western-digital/collateral/tech-brief/tech-brief-hgst-micro-actuator.pdf

I found this interesting: https://documents.westerndigital.com/content/dam/doc-library/en_us/assets/public/western-digital/collateral/tech-brief/tech-brief-hgst-micro-actuator.pdf

![]() ah yep that is somewhat reminiscent of a hard drive head flexure

ah yep that is somewhat reminiscent of a hard drive head flexure

@placethesundontshine for sure! I hope you guys can help me to test the performance and publish in HardwareX

@placethesundontshine for sure! I hope you guys can help me to test the performance and publish in HardwareX

![]() How do you make the flextures? Wire EDM?

How do you make the flextures? Wire EDM?

What did you use the 7 axis stage for out of interest? very cool!

What did you use the 7 axis stage for out of interest? very cool!

Exactly, LEGO2NANO....I developed atomic force microscope (normally 100k USD) that can be assembled by school kids and get nano resolution imaging

Exactly, LEGO2NANO....I developed atomic force microscope (normally 100k USD) that can be assembled by school kids and get nano resolution imaging

@John exactly! I love EDM ;3

@John exactly! I love EDM ;3

7 axis stage was for graphene deposition and manuplation....

7 axis stage was for graphene deposition and manuplation....

Time for a DIY EDM Hack Chat, methinks...

Time for a DIY EDM Hack Chat, methinks...

Play Video

Play Video

The rotating screw will be very usefull in optics...

The rotating screw will be very usefull in optics...

how is it working?

![]() I wonder what will happen to motor prices when the first NewScale Squiggle patent expires

I wonder what will happen to motor prices when the first NewScale Squiggle patent expires

(I guess similarly to the picomotor stuff, but I cant imagine)

(I guess similarly to the picomotor stuff, but I cant imagine)

The rotary one is using two pzt and contact ped to drive the screw in opposite direction...

The rotary one is using two pzt and contact ped to drive the screw in opposite direction...

Actually that's different from picomotor ;p

Actually that's different from picomotor ;p

Does the use of the screw mean it also has high driving force and is it locked when powered off?

Does the use of the screw mean it also has high driving force and is it locked when powered off?

ok

ok

@Merijn Otterman exactly! this rotary piezo motor can drive 5 kg load vertically

@Merijn Otterman exactly! this rotary piezo motor can drive 5 kg load vertically

Are there any low cost commercial controllers you recommend? I'm excited to try to machine one of the axis in my garage!

Are there any low cost commercial controllers you recommend? I'm excited to try to machine one of the axis in my garage!

haha....the commercial controller I like is from AttoCube, but cost 15k USD

haha....the commercial controller I like is from AttoCube, but cost 15k USD

You can use Arduino plus DAC board plus piezoDrive HV amplifier

You can use Arduino plus DAC board plus piezoDrive HV amplifier

lol, low cost is relative

lol, low cost is relative

https://www.adafruit.com/product/935

ADAFRUIT

ADAFRUIT INDUSTRIES

MCP4725 Breakout Board - 12-Bit DAC with I2C Interface

Adafruit Industries, Unique & fun DIY electronics and kits MCP4725 Breakout Board - 12-Bit DAC with I2C Interface [STEMMA QT / qwiic] : ID 935 - Your microcontroller probably has an ADC (analog -> digital converter) but does it have a DAC (digital -> analog converter)??? Now it can!

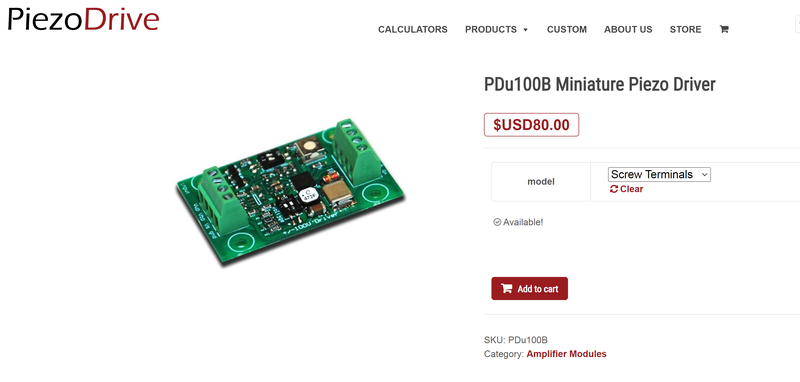

https://www.piezodrive.com/modules/pdu100-micro-piezo-driver/

PDu100 Micro Piezo Driver | PiezoDrive

The system block diagram is illustrated in Figure 2. A boost converter generates a high-voltage rail to supply a pair of complementary amplifiers. A single output can be used to drive a unipolar load up to +100 V or both amplifiers can be used to produce +/-100 V.

I think the Arduino and boards combination can get you nice control within 200 USD

I think the Arduino and boards combination can get you nice control within 200 USD

![]() is the rotary unit published? and is backlash not a problem the thread?

is the rotary unit published? and is backlash not a problem the thread?

@Prof. Jim Brenner super cool! :D

@Prof. Jim Brenner super cool! :D

200USD per axis?

200USD per axis?

@placethesundontshine not yet... :(

@placethesundontshine not yet... :(

200 USD 3 axes....the PiezoDrive board costs 1XX USD, DAC 18 USD, Arduino XXUSD

200 USD 3 axes....the PiezoDrive board costs 1XX USD, DAC 18 USD, Arduino XXUSD

Nice, do you machine any of your parts in your lab or send them out to be made?

Nice, do you machine any of your parts in your lab or send them out to be made?

@Hash my institute in Taiwan has super nice workshop with EDM, machine center....

@Hash my institute in Taiwan has super nice workshop with EDM, machine center....

![]() @Dan Maloney: when I scroll up half a message (from the last ones) every second or so the chat scrolls down automatically. Is there a way to disable this behavior?

@Dan Maloney: when I scroll up half a message (from the last ones) every second or so the chat scrolls down automatically. Is there a way to disable this behavior?

![]() Would a stepping piezo motor be easier controller-wise, not needing high voltage driver and allowing greater range of motion?

Would a stepping piezo motor be easier controller-wise, not needing high voltage driver and allowing greater range of motion?

PiezoDrive can replace my previous hv amplifier....100b has two channels

PiezoDrive can replace my previous hv amplifier....100b has two channels

@John yeah...if you don't go Z direction...30 to 50V is enough

@John yeah...if you don't go Z direction...30 to 50V is enough

@mh-nexus - Sadly, no. But I will have a transcript ready soon after the chat, so you can refer back to anything you've missed

@mh-nexus - Sadly, no. But I will have a transcript ready soon after the chat, so you can refer back to anything you've missed

![]() @Edwin Hwu what's the limit on range of motion in x-y?

@Edwin Hwu what's the limit on range of motion in x-y?

@Prof. Jim Brenner one company licensed my patents...they sell AFM for 3k USD ;)

@Prof. Jim Brenner one company licensed my patents...they sell AFM for 3k USD ;)

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.