Welcome!

⚠️DISCLAIMER⚠️

The content presented on our website, YouTube channel, Download Kit, and all other internet and real world presences, regarding potentially hazardous processes is for educational purposes only.

Viewers are hereby cautioned against attempting to replicate any techniques or procedures demonstrated unless they possess the necessary legal qualifications and certifications.

We expressly disclaim any liability for consequences arising from the replication of such activities without proper authorization or expertise.

Viewers are advised to seek professional guidance and adhere to applicable laws and safety regulations before undertaking any similar endeavors.

⚠️⚠️⚠️

Our 2022 Hackaday Prize Contest Entry Video

Quick Links

The Problem

You all know that plastic waste is bad so I'm going to summarize the scale of the problem simply with 5 numbers.

Every year we produce over 350 million tons of new plastic.

Since its invention, over 9 billion tons of new plastic has been produced.

Since its invention, over 9 billion tons of new plastic has been produced.

More than 90% is recyclable...

...but less than 10% actually gets recycled.

This means that there is over 6 billion tons of plastic waste in the world right now, ready to be collected and recycled.

So even if we completely stopped producing plastic right now there is still a little bit we need to tidy up.

If left uncollected it remains in the food, water and air that we humans and almost every other living thing, in our ecosystem, are at risk of consuming and being polluted by it.

The Challenge: Reuse, Recycle, Revamp

We are working to dissolve the economic, technical and social barriers that prevent people from getting recycled plastic products into the world.

Our project is all about increasing accessibility to recycling equipment and hence enabling more people to recycle.

Why?

Recycling provides a solution to both:

1. Extracting raw plastic pollution from the environment by capturing and storing it in large pieces that are kept out of the ecosystem by human utilisation and are easy to manage at the end of their product life to ensure that they do not end up back in the ecosystem.

2. Providing an alternative to dependency on raw materials. Humans are always going to make things, by using recycled materials we reduce the extraction of raw material, such as wood, and its inherent burden on the environment.

Our solution, a recycled plastic skateboard deck (RPSD), is to provide the means to produce a fun, healthy and directly tangible reward for recycling that demonstrates both the aesthetic beauty and the mechanical strength of the material to its users and observers, with the aim of incentivising and catalysing plastic recycling.

A skateboard was also chosen because of its ease of manufacture. We want it to be as easy as possible for people to recycle, so we chose a simple product with no, ribs, undercuts or complex geometry and just one single solid body. This is our way of trying to dissolve any technical barriers, potential manufacturing defects and complications that would stand as obstacles in the production process.

Ease of access is why all of our research is, and always will be, open source. To reduce the barriers that IP restrictions, copyrights and patents place in front of designers and recyclers who want to start recycling. We want anyone, anywhere to be able to pick up our project with as little resistance as possible and start recycling plastic.

The process to build the mould itself has been designed to be as easy to replicate as possible without any specialist tooling, just things found in a standard metalworking workshop, a grinder, a pillar drill and a welding machine. This is to prevent economic, infrastructure and skill-level barriers from standing in the way if people building our system.

The Mould

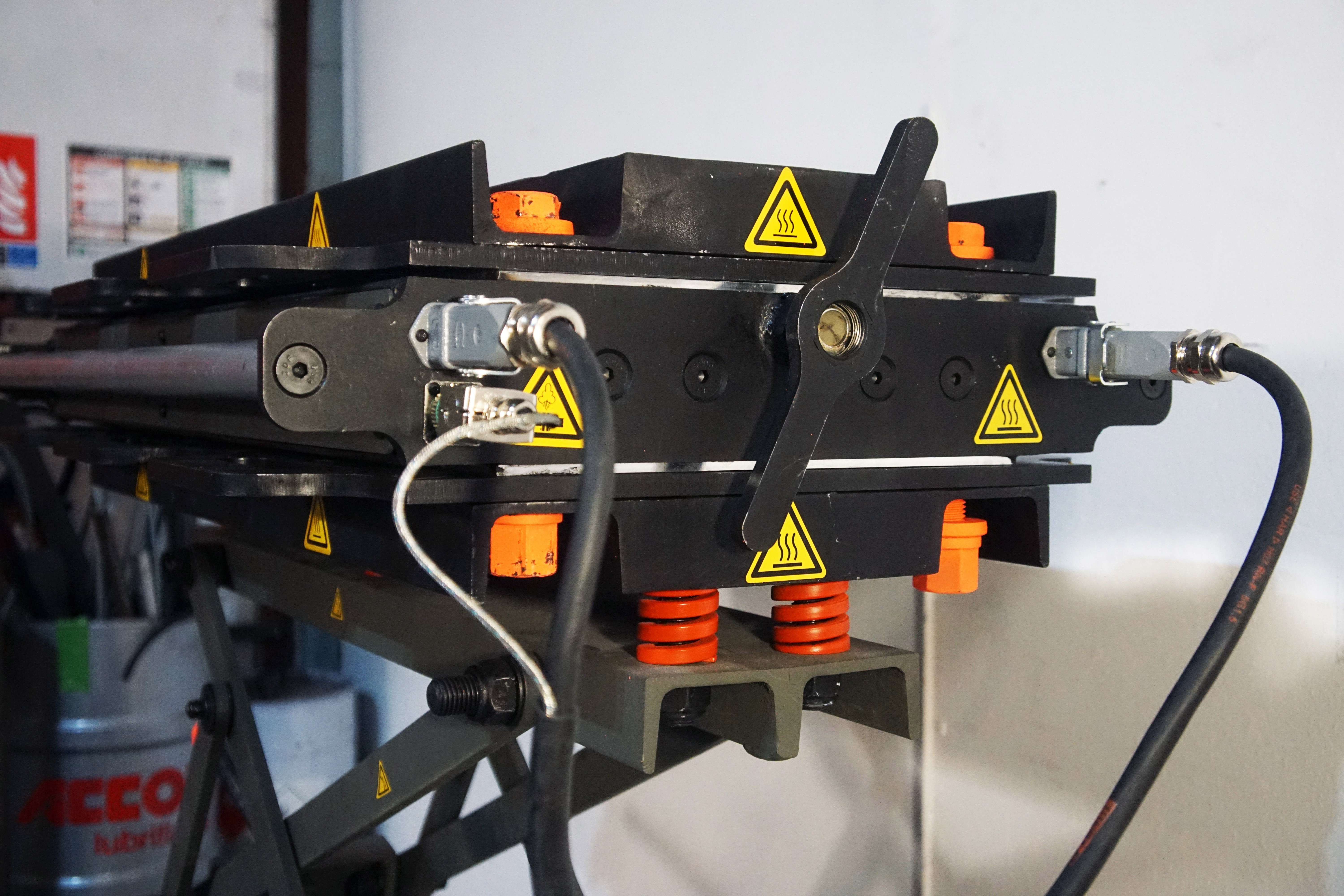

The most technically innovative and unique part of project RPSD is our open-source mould, which is used to form the skateboardsc decks.

Previously it did not exist, which means we can proudly say this is the first in the world of its kind to be released.

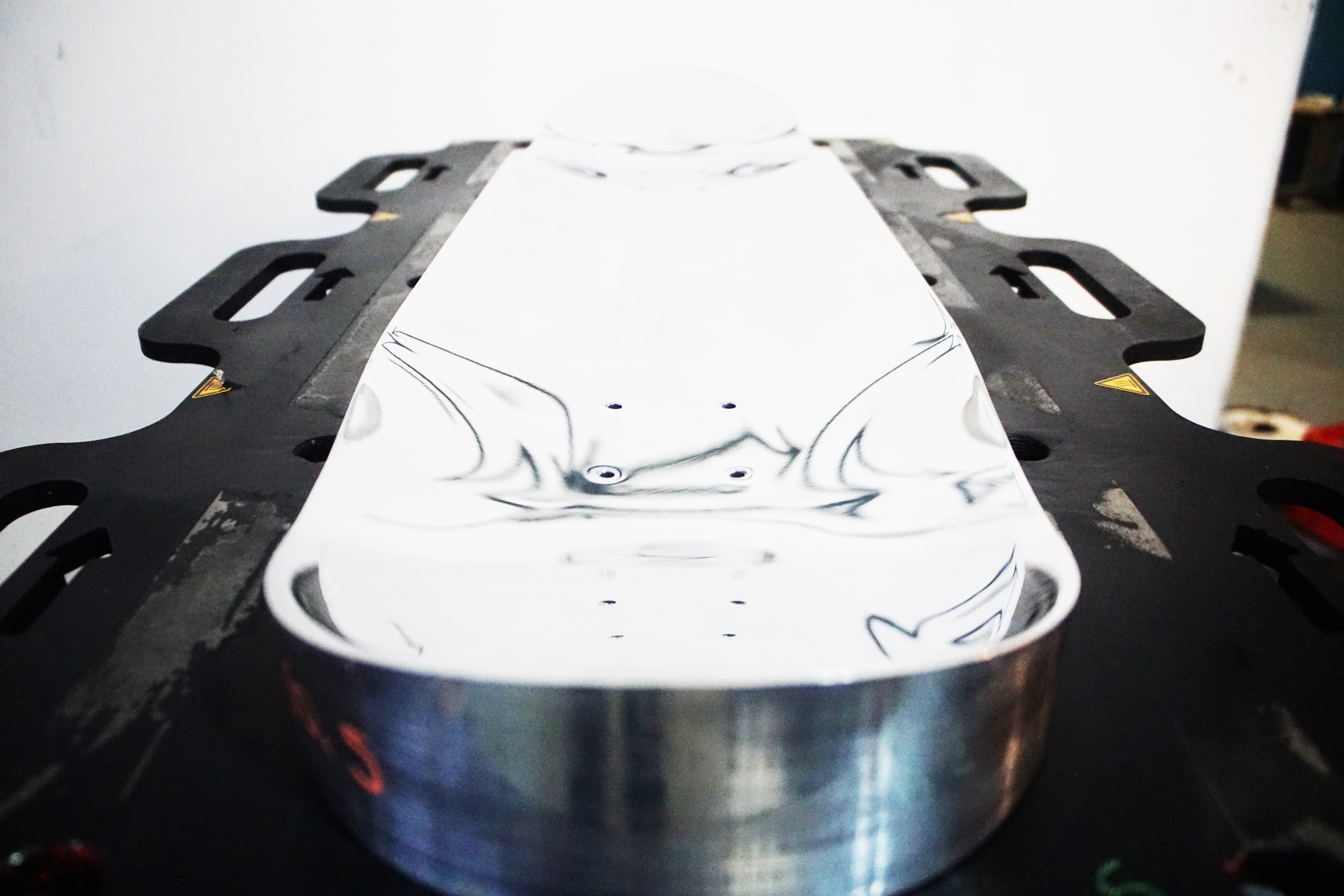

The mould consists of three CNC cut aluminium pieces that form the shape of the deck.

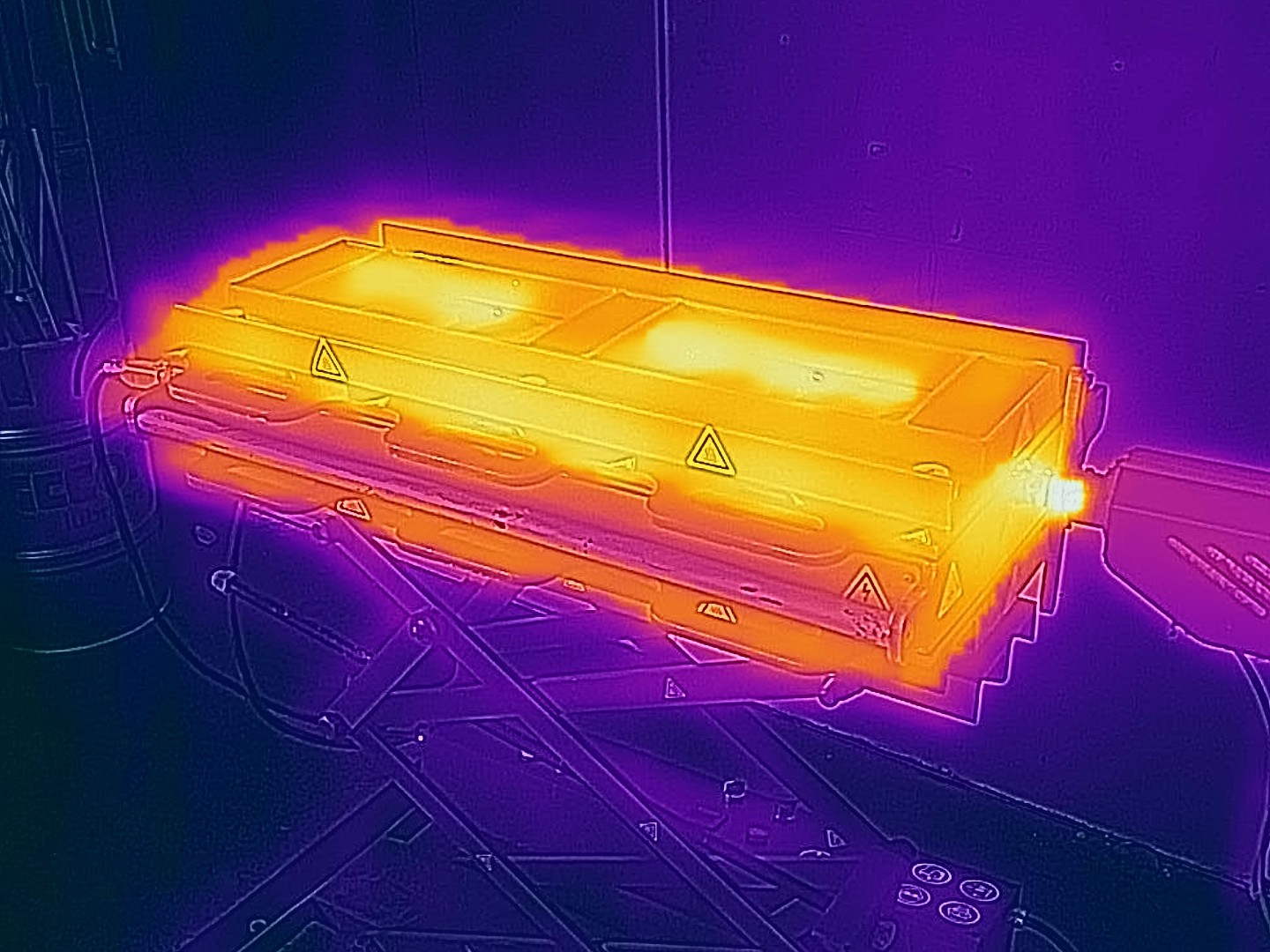

The mould is electronically heated, with cartridge heaters similar to those found in 3D printers, whilst molten plastic is injected into the mould using an extrusion machine.

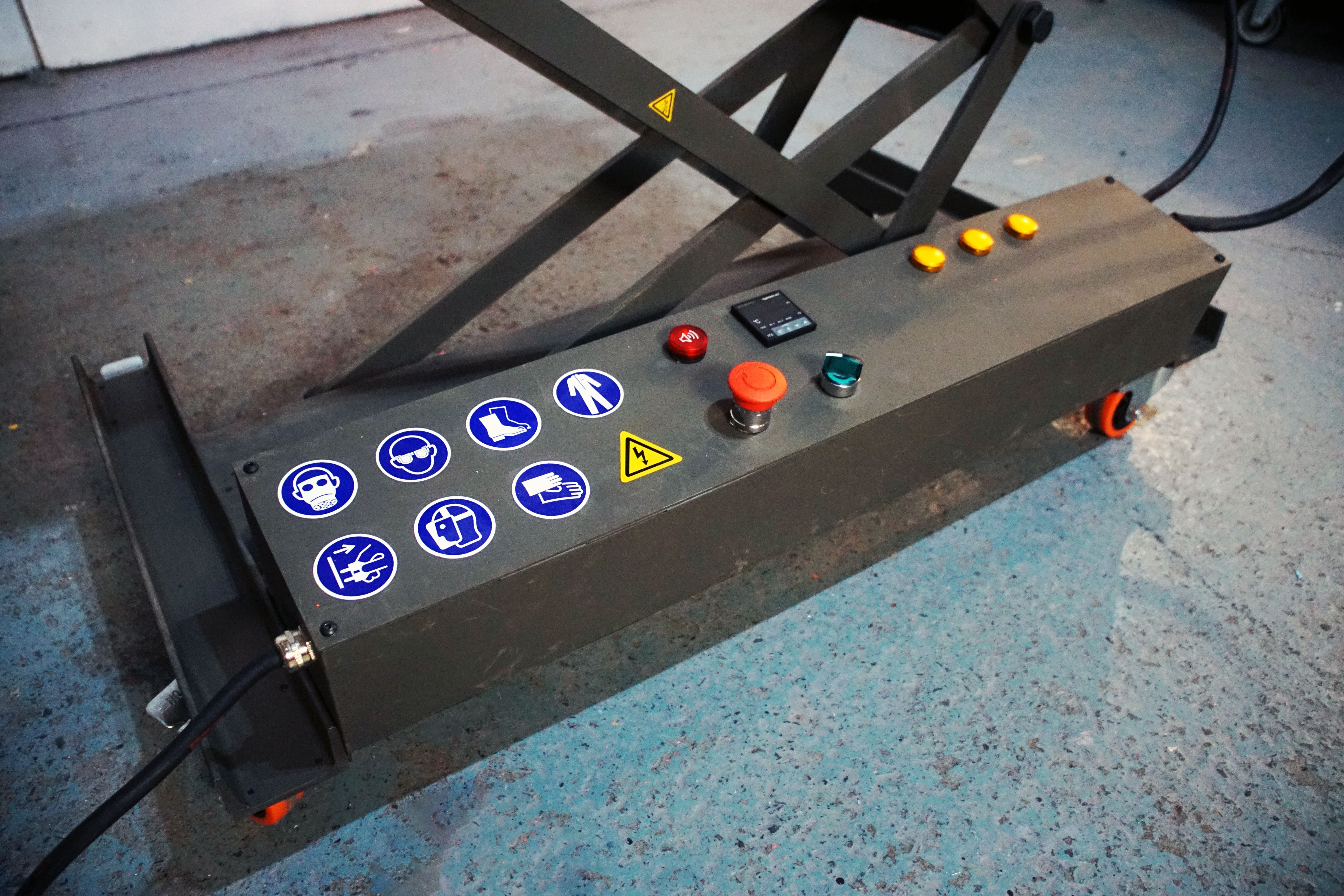

It also features an adjustable height table, a quick-release handle and suspension for easy operation.

The Decks

The deck has 8.25” width, 32” length, and a 14.25” wheelbase, with a medium concave This is the average take from a survey of skaters with the aim to design a deck size which fits the most universal needs of skaters.

The type of plastic you use to make the deck defines its weight, for example, decks made from PP (Polypropylene) wight 1.75-1.8kg.

The thickness is calibratable so you can make different thickness decks depending on the strength and stiffness of the material.

The unique thing about a deck made from recycled plastic is that, unlike a wooden deck, the shape does not need to be the same thickness all across the deck, this allows us to take away a little bit of material where it is not needed to make it lighter, and add a bit of material where it is needed to make it stronger.

Full Project Description

What

Tackling plastic waste, democratizing access to skateboarding & proving to people what products made from waste can really do through the production of recycled plastic skateboard decks.

This is achieved by pioneering plastic recycling research, which we publish online, open source, for free. Then providing support in the form of consultancy, hands-on help, and funding, to help people set up their own recycled plastic skateboard deck workspaces.

Why

Our impact can be split into four categories:

- Environmental

- Increase the amount of plastic recuperated from waste streams, and hence prevent it from turning into pollution. Every year we produce over 350 million tons of new plastic. Since its invention, over 9 billion tons of new plastic have been produced. More than 90% is recyclable but less than 10% actually gets recycled. This means that there are over 6 billion tons of plastic waste in the world right now, ready to be collected and recycled. This plastic ends up in the food, water, and air that all living things on our planet consume.

- Reduced deforestation. Traditionally skateboard decks are made from Canadian Maple Plywood and are the single biggest contributor to their deforestation.

- Less CO2 emissions and strain on transportation systems by localizing production of skateboard decks. Over 90% are made in North America and China and distributed globally.

- Social

- Democratize access to skateboarding. Skateboarding, as a hobby, remains out of reach to many due to their economic situation and hence lack of other financial or material resources to participate in skate culture. Making decks from waste dramatically reduces cost & hence increases accessibility.

- More people are able to participate in sports, as a direct result of eased accessibility, which brings the inherent health and social benefits of being part of a sporting community.

- Economic

- Create and stimulate small-mid sized localized circular plastic recycling economies. Currently waste is one of the newest resources humans are realizing they can tap into for economic gain, but this practice is relatively young and the information and know-how needed to do it successfully are not significantly abundant to match the magnitude of the problem. We want to spread this know-how and catalyse its implementation however necessary.

- Create jobs in the sustainability sector. This can also be viewed as a social motive. Unemployment is a global problem, with waste recovery not being fully utilized, a pairing of the two problems creates a symbiotic relationship.

- Emotive

- Change people's perspective about plastic waste from seeing it as something that can only be discarded or used to create sub-standard products, both aesthetically and mechanically speaking, to seeing it as material you can use to make something beautiful, strong and useful.

- Provide people with a fun, tangible reward for plastic recycling, hence incentivizing them to recycle.

- Get people to associate the act of recycling with a positive emotional experience by making it exciting and playful.

How

The actual production of decks is achieved by researching plastic recycling, which we publish online, open source, for free. It always has been and it always will be, so that anyone, anywhere in the world can pick it up, develop it, rework it and implement it, on the condition that they share their results back. The goal of the project is not to monopolise production but act more as a facilitator to enable and empower others, by making it as easy as possible for people to start making desirable products from recycling plastic.

The conceptual origin of the project comes from an artistic motive, to create a perspective change in how people view plastic waste. Skateboard decks were not a randomly selected product but a carefully analyzed and holistically considered choice, its most significant three reasons being:

- Skateboards communicate the strength of the material.

- The thing that often stands out about products made from recycled plastic is the beauty of their appearance but what’s often overlooked is their strength & durability. Skateboard decks were chosen because they demonstrate this. When people see someone riding a deck, a thin slither of recycled plastic, that takes hard knocks and scrapes, they are conveyed the idea that the material is strong & durable. This plants the seed of taking the material more seriously, challenges the idea that just because the material is not in its first time through the consumer cycle that its quality and potential is compromised, and inspires people to consider using it for purposes that they previously would not have. The medium for communicating this can be in the format of pictures, video and demonstration.

- Tangible, fun and healthy reward.

- Modern recycling systems are a relatively opaque and abstracted process. Your recyclables are collected by the waste collection system, they disappear, and are processed without you knowing the details of what happens or directly receiving the reward for making the environmentally ethical and responsible effort of ensuring they are recycled. Alternatively, by using plastic waste to create a skateboard deck, people receive a direct, tangible reward that is fun, hence making it desirable, with the added benefit of being something that is good for their health to use.

- Ease of manufacture

- Plastic, being a very versatile material, can be used to make objects big and small, in a variety of shapes, with intricate and microscopic detail, but with this variety of shape and detail comes complexity of manufacturing process and high tolerance requirements. The more physical detail and complexity the product has, the harder it is to make and the more likely it is to fail in the manufacturing process. Skateboard decks are a relatively simple shape; having no small details or complex shapes. We want the product we implement to be easy and hassle-free for people to make.

Our most significant technological development is designing and building our own manufacturing system that allows skateboards to be produced at a low cost and with a small amount of infrastructure, e.g. in a domestic or small commercial context using basic tooling. The manufacturing system uses a combination of a custom-designed and built mould supported by pre-existing open source machines, e.g. an extrusion machine and plastic shredder.

The most innovative and unique element of this project is the development of the mould used to make the decks, as this has previously not been achieved, so we can say, proudly, that these are the first, and only, traditional popsicle skateboard decks in the world to be made from recycled plastic. There is no existing documentation published about how to use this equipment to produce a traditional popsicle skateboard deck. Hence, this has been the concentration of our efforts since the beginning of the project. Documentation on how to use the extrusion machine and plastic shredder exists and has been popularised by the machine development community, Precious Plastic. The machines are being replicated & used by 1000s of people all over the world so there is already an expansive network of recyclers & machinists familiar with the process involved, ready to integrate the mould into their manufacturing system. In addition to this pre-existing manufacturing network, our goal is to help more people join and get set up to start recycling.

Our research is published in the format of Download Kits, containing all the information people need to set up their own skateboard deck production, with supporting detailed instructional videos.

The download kit will include:

- Engineering drawings

- Electronics schematics

- Assembly guide

- Build video

- Usage video

- Technical data sheets

- Bill of materials

- Links to supporting machine download kits

- Digital business + community building tools

When

- Then

- Prototyping began seven years ago in the framework of a research project as part of Jason’s bachelor's degree. At this point in history the machines used today to create the decks did not exist. Jason has both studied and worked in parallel with the machine developers to push the technology forward to a point where it is possible to use for deck production.

- Now

- The next version of the project is scheduled for release on April 22nd 2022 (World Earth Day) on our new web platform, where all of the above mentioned content can be found.

- Next

- Pilot projects: Implementing the newly designed system in real world contexts.

- Events: Demonstrations at festivals, educational institutions, sports events etc.

- Media creation: Publishing skate videos, pictures and any other medium suitable to showcase the decks and system.

- Research: Open-source research to further develop the production system, its useability & surrounding technologies. E.g. trial production and material and technique experimentation.

Jason Knight

Jason Knight