I currently think of using the N20 gear motors for flatcat mini. They are widely available, affordable and robust.... ...and much much smaller than the motors of big flatcat.

It seems obvious that the current Sensorimotor boards are way to big. So they certainly need a redesign, too :) But for now, i'll take them _as they are_. USE WHAT YOU HAVE!

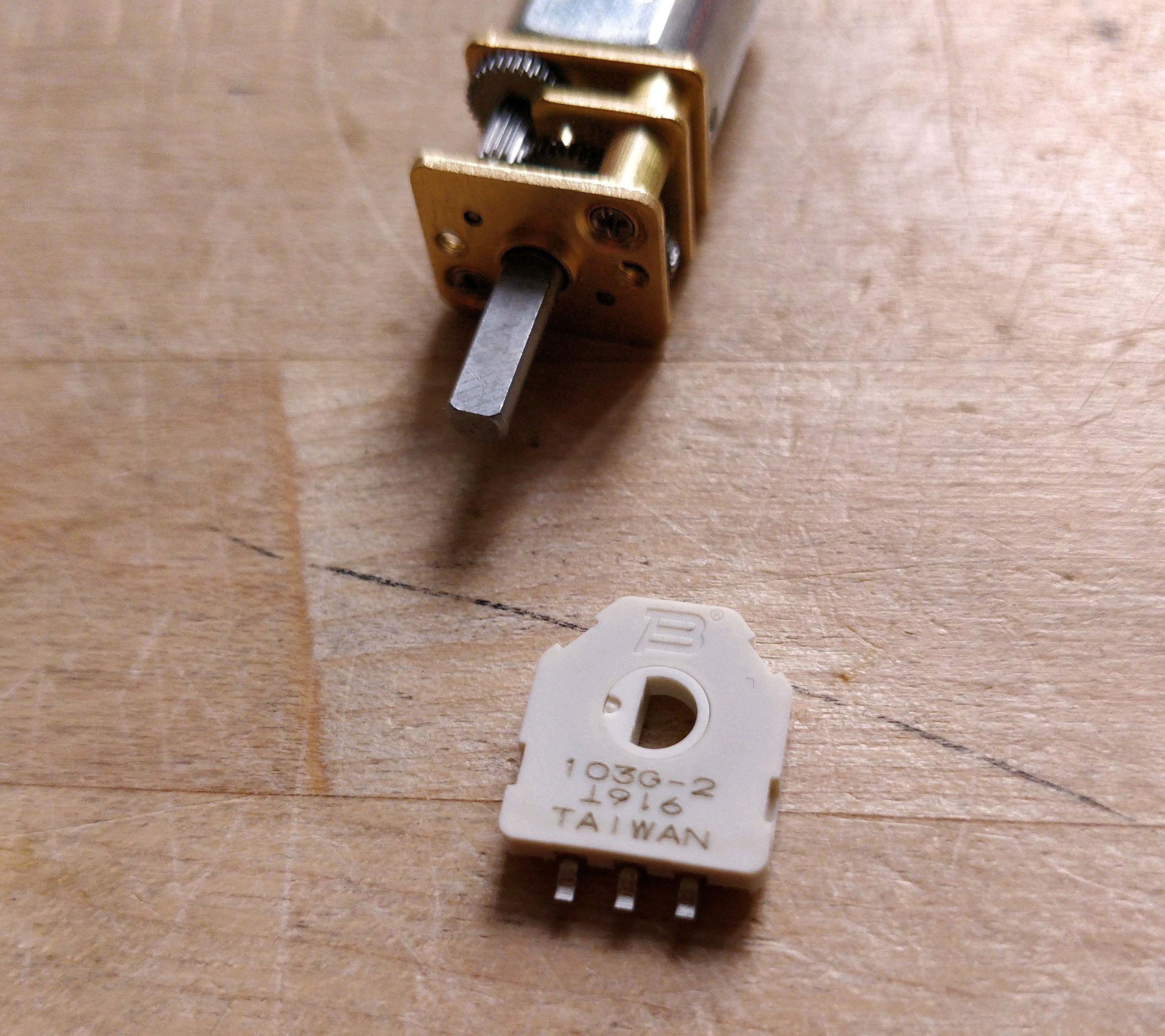

found a nice position sensor for the N20 motor. it's basically a flat potentiometer, not 360 deg but sufficient for the mini's joints.

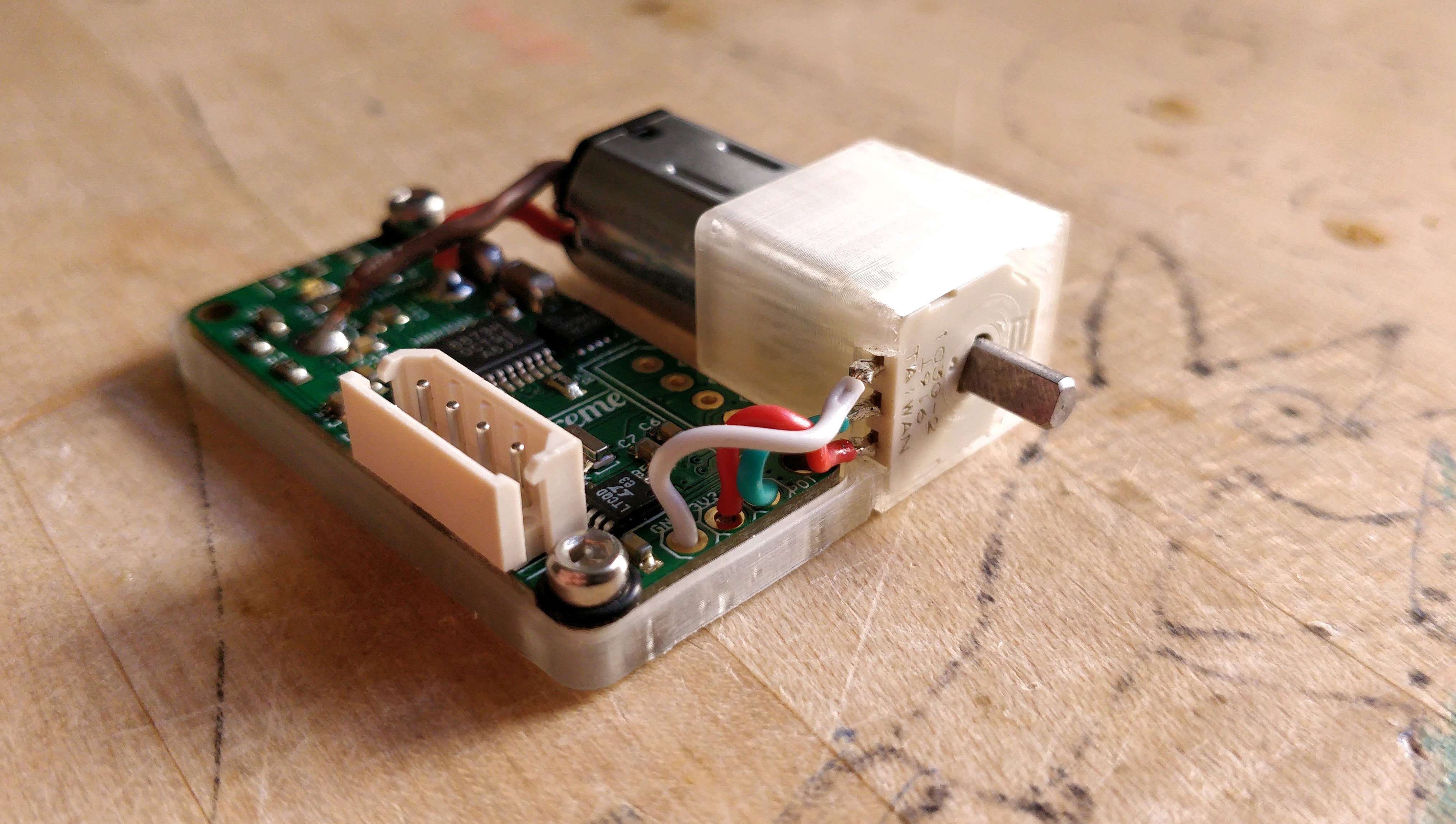

after a little bit of CADing in fusion, i integrated the dc motor, sensorimotor control board and the potentiometer in a nice tiny test setup. the sensor is SMD so the pins were way to small for comfortable soldering, but hey. ready to test.

Matthias Kubisch

Matthias Kubisch

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.