For smaller stores, pigment comes in 1 quart cans or jars, for larger stores it’s containers up to 5 gallons. For the donor businesses the effort would be minimal - put the cap back on and keep the empties in a box until whomever is going to convert the pigment can pick it up. There’s value in making donation that easy.

Although most pigments can be converted into watercolors, gouache, oils, acrylics, encaustics (and probably others), I’m developing my formula for watercolor first because you can make a lot of paint relative to pigment volume, the other ingredients are pretty inexpensive, and it can be stored dried in pans, as opposed to having to be kept wet like acrylics or oils.

I’ve already successfully made hand milled watercolor with gum arabic, gylcerin, and honey. As beautiful as the historic process of hand worked glass mulled paint is, that isn’t practical for busy art teachers, or the kind of people inclined to work with community organizations.

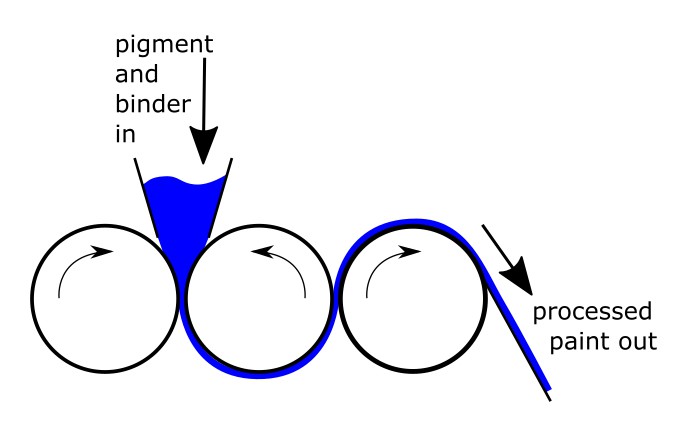

Right now my focus is on a small desktop three roll milling machine. It’s a common way to manufacture paint, and produces consistent, good quality results quickly and with low physical labor involved. To buy a milling machine starts at around $1000 US, so I have a lot of room to undercut that with my open source version. Since the pigment is already pre-milled to very small particles the equipment will primarily need to make the ingredient mix consistent and eliminate any larger chunks. I can’t find any precedent for DIYing a three roll mill, so I’ll be completely working from scratch, and an accessible desktop milling machine could be useful for many kinds of project. I also have some ideas for add-on tools to create after the milling process is established.

My conversion system will to be open source with the easiest to source materials possible. I’m using an Ender 3 printer (sub $200 cost) to make any parts that aren’t commercially available.

Since I’m already using a 3d printer, I’m also printing my watercolor pans with it. They are weirdly expensive to buy, and right now I’m getting about 644 half pans (the most common size) per 1kg spool of PLA. I buy my PLA in bulk for $10 US per kilogram, so each costs about $0.015 in materials.

Roadmap

- Finalize Recipe/Technique

- Design and Prototype Milling Machine

- Design Storage (Watercolor Pans)

- Documentation/Parts List/Printer Files/Build Instructions

- OSHWA Certification

technoplastique

technoplastique

Hi, Would you be able to tell me the pigment names/numbers and the percentages in the solutions please. I am working on a project that uses pigments and even though I am not in the US, it would be good to make mi project compatible with the supplies you discovered.