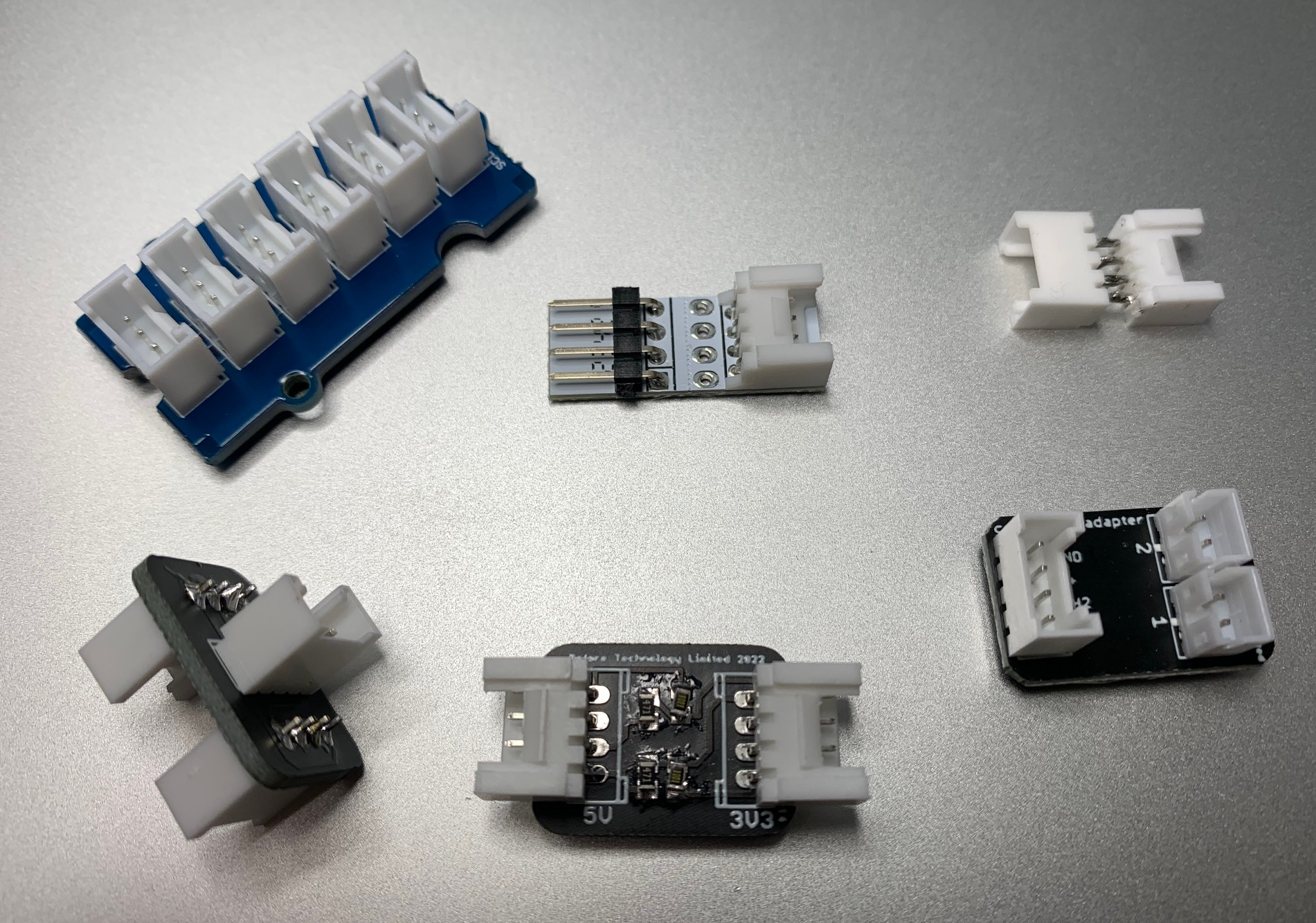

The first couple of board batches have been primarily human-machine interface (HMI) and interconnect components.

The HMI component collection so far includes:

- 5mm LED

- 5mm bicolour LED

- button

- LED/button

- pot

- multi-position switch (4 positions)

- toggle switch

- rotary encoder

All of these components can be panel mounted. The boards convert the pin connections into a Grove/4 pin JST PH or 2 pin JST PH connector. In some cases resistance is added eg for LEDs. The boards are extremely simple, and the layout time was minimal. The boards are small, so the cost is low when buying in volume.

The composite HMI is wired with PH and Grove cables, which can optionally be consolidated into byte-wide breakouts. Then a 10-wire JST PH connector is used to carry signals back to the MCU.

M3 or #4-40 standoffs and screws are used for mounting. I chose #4-40 over M3 because we have a local supplier that stocks these and they are cheap.

While this concept may use more parts, it all comes apart and there is very little waste. The only part that cannot be easily reused on this first demo HMI is the acrylic panel.

There are a lot of other kinds of components that should integrate using the same methods of mounting and interconnect. Displays, keypads, communications interfaces, motors, storage, and so on.

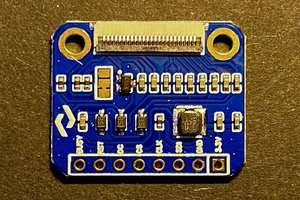

All of types of modules are available in some form, and when components already exists that fit the design pattern, then these will be specified rather than creating new modules. In some cases I will be creating carrier boards that provide the desired interconnect, mounting, and other features, so that the components are easily integrated.

Also there are a variety of simple boards required in support of interconnect.

Tom Dowad

Tom Dowad

MagicWolfi

MagicWolfi

MaBe42

MaBe42

Ace

Ace