E-TKT: anachronic label maker

Andrei Speridião 2022 - http://andrei.cc

📺 media

E-TKT has already been featured in several places:

- Digi-Key Maker Update (project of the week) — “Ep.289 - Stamp of approval”

by Donald Bell — June 30, 2022

- Make: “Old School Label Making, New School Interface”

by Caleb Kraft — June 22, 2022

- Hacksterio “E-TKT Prints Embossed Labels with the Power of IoT”

by Arduino “having11” Guy — June 17, 2022

- HACKADAY “DIY AUTOMATED PRINTER KERCHUNKS OUT CLASSIC EMBOSSED LABELS”

by Dan Maloney — June 15, 2022

🤓 about E-TKT

By combining simple and widely-available embossing tapes in a reliable mechanism with modern connectivity, E-TKT rescues a would-be future that did not happen, and at the same time gets rid of the dependence on proprietary cartridges, which are environmentally impacting & expensive.

🧐 what?

étiquette f (plural étiquettes)

“ticket, memorandum, attach, stick, pierce, sting, to be sharp, goad, puncture, attach, nail”

- tag, label

- prescribed behavior

It’s curious how both meanings are a consequence of each other: we name things around to state and reinforce what they are or should be, and at the same time, we end up influencing our own behaviors mediated by these labels.

🤔 why?

TLDR: curiosity, technical challenge and of course organizing stuff.

The initial spark for this project came from an ordinary manual labeling device that I bought to organize my workshop. I was VERY UPSET when I noticed that it was basically rubbish, getting broken and unusable after just a few operations. Just to imagine something made in another part of the world, travelling to me and breaking this way is unbelieavable.

Instead of embossing, it was really embarrassing labels 😅

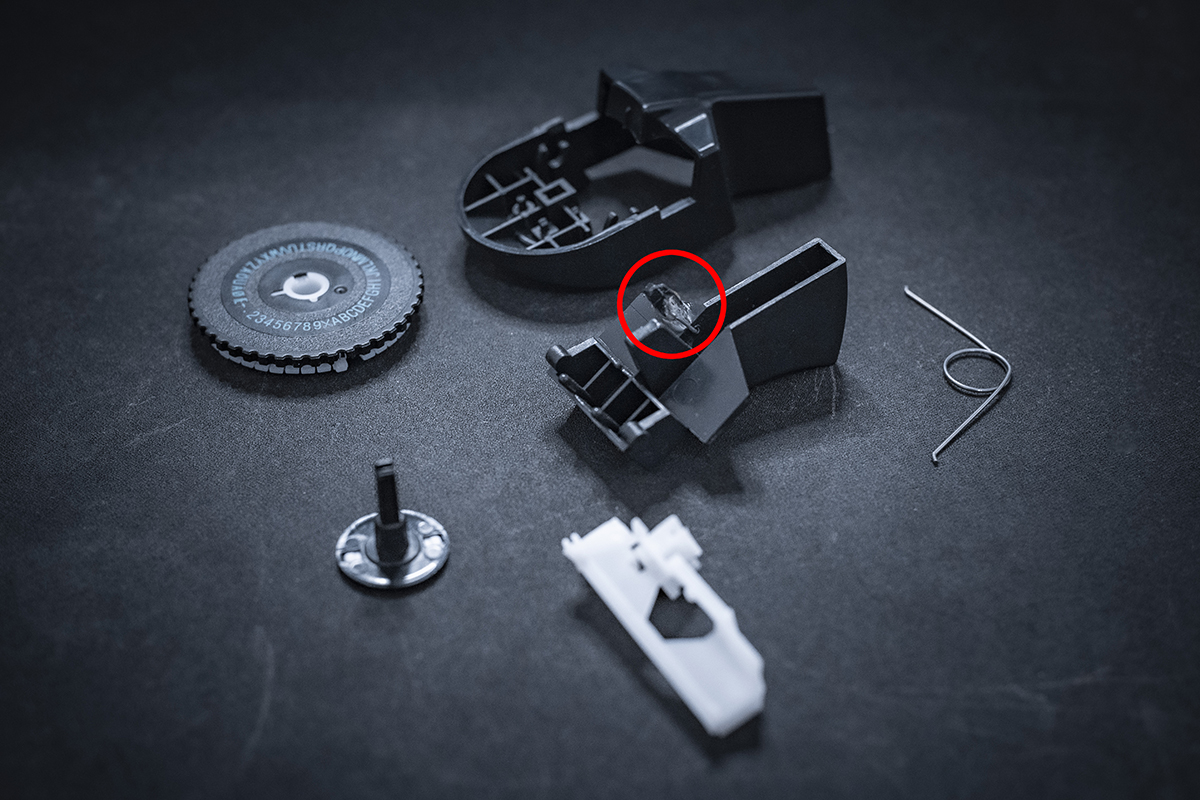

This little plastic hook (circled in red) grabs a ratchet mechanism (the white plastic part below) to feed the tape forward. I tried to fix and reinforce it, but the failure was unavoidable because there seems to be a critical flaw in the project: it is too weak for the lateral force imposed.

At that moment, I could easily buy a brand-new electronic thermal label printer (such as this Brother model), but something about the vintage embossed finish fascinated me. Also, these new models use expensive DRM proprietary cartridges that create a lot of trash after use, not to mention that some other recent models are DRM protected.

After all, even though the pressing mechanism was poorly made, the daisy wheel was pretty sturdy and sharp-printing. So I thought: can I build over its principles to create a functional device? If so, then why not make it physical-digital?

…why bother mixing an archaic printing method with current automation and connectivity features? Because why not? It was a technological blind spot ready to be explored!

🤯 reasoning: context & purpose

- ACCESSIBILITY: braille labels are only a step of distance for a possible future spin off.

- CULTURE: embossed labels are deeply ingrained in culture, as well pointed by Dan Maloney (HACKADAY), spacestationkru (reddit) and agent_kater (reddit);

- NICHE NEEDS: there are situations where a paper, flat and/or thermally printed label doesn’t fit the needs, let alone the need for the embossed relief;

- ERGONOMICS: when there is no other way than using embossed labels, making them manually is a straining process that might give the operator repetitive strain injury;

- REACH: this is a cheap mass-produced device, meaning that lots of people around the world might have one at home or work;

- ENVIRONMENT: these devices might be already broken: how many kilos of wasted plastic (plus the shipping impact)?

- ISSUES: of course, these folks will be upset and in the end have their needs unaddressed;

These factors made me think of E-TKT as more than a solution only for myself, but to everyone.

I wanted to create an open source project for a long time and this is why I put a lot of effort into testing all parts extensively and of course crafting this detailed documentation.

🤓 exploration: …anachronism

During the process I’ve realized that this odd mix between new and old was the biggest underlying curiosity. According to Wikipedia:

“An anachronism (from the Greek ἀνά ana, ‘against’ and χρόνος khronos, ‘time’) is a chronological inconsistency in some arrangements, especially a juxtaposition of people, events, objects, language terms and customs from different time periods”.

The point is: even though the process is digitalized, the resulting label is totally old school and there is no easy way of telling if it wasn’t made in the traditional way.

⚙️ how does it work?

An ESP32 commands the label production and also serves an on demand web application (local) to any device connected in a local network.

Neither internet is needed, nor installing any app.

Configuration

The whole process of connecting the E-TKT machine to a local network and then launching the local app is aided by a small OLED display that provides instructions and a dynamically generated QR code with the URL, according to the IP attributed by the WLAN.

Commands

The web app provides instant text validation, buttons for special characters, a preview of the physical size of the tape, an option to select the desired lateral margins and also real time feedback during the printing process (also present on the device screen). There are specific commands for manually feeding and cutting the tape, and a setup menu where the user can feed a new tape reel and calibrate the machine by adjust the letters alignment and pressure force applied to the daisy wheel.

Embossing

The label production itself uses the same mechanical principles as the original machine, but is now reliable and automated. A stepper motor feeds the tape while another selects the appropriate character on the daisy wheel according to a home position acquired by a hall sensor. Then a servo motor imprints each character by pressing it’s daisy wheel tooth against the tape. That happens successively until the end of the desired label content, when there is a special character position to cut it off. A light blinks to ask for the label to be picked.

🧱 Functional block diagram

🔖 cost per unit

The estimated cost for the components (without attrition) is around $100 (USD) without shipping and taxes, as of October 2022.

This value takes into account all the breaking points for a single E-TKT device and includes the manufacturing of 5 PCBs (4 layers) plus a stencil for the front layer.

⚖️ license

E-TKT by Andrei Speridião, 2022

Software

Hardware

Documentation

Creative Commons Attribution-ShareAlike 4.0 International Public License

If you ever build one, I would love to know ;)

💡 features

🌟 highlights

- No need for internet, app installation, data cables or drivers;

- Command it from any device that is connected to a local network and has a web browser: desktop, tablet, smartphone;

- Compatible with ubiquitous, DRM-less and cheap 9mm generic tape (DYMO-compatible);

📱 web app (local)

- Instant preview simulation: what you see is what you get;

- Dynamic check for character validity;

- Estimate of the resulting label dimensions;

- Automatic text centering;

- Margin modes: tight, margin (1 space on each side) or full (maximum input length);

- Buttons for special characters: ♡ ☆ ♪ $ @

- ”+ REEL” function to install a new tape reel;

- Manual commands: feed & cut;

- Calibration setup for fine tuning the character alignment and pressing force.

🔌 device

- Full label embossing & cutting;

- Speed: 10 characters per minute;

- Minimum label size to be pickable from the device;

- OLED screen + LED feedback;

- QR code & URL for easily accessing the web app;

- Real time embossing progress;

- Instructions for configuring the wifi;

- Button for clearing the wi-fi configuration;

- Sound signature: each label owns a subtle melody 🐰🥚

Andrei Speridião

Andrei Speridião