-

Success!

07/16/2022 at 13:43 • 0 commentsMy 50 year old reel to reel deck has given up all it's secrets and is now spinning along like it was built yesterday. Almost anyway. The motor fan is making a tiny bit of noise, so I will probably have to take the unit apart and adjust the spring holding it, but it is now playing tape perfectly at factory speeds.

Luckily my guess about the 1.5+0.5uF run capacitor seems to have been right, as the motor now spins absolutely silently with a replacement 2uF (400V rated) motor run capacitor.

Luckily I caught another issue at the same time. The motor has some filters to prevent spikes when the motor turns on and off. Let's just say one of these pop filters have popped and I was lucky to get it replaced at the same time - I probably should've replaced both but time was running short.

After I barely managed to fix the thing before going on holiday - not intending to bring a tape deck that weighs about the same as the rest of my luggage - I also managed to get some raw video of how it works together with my #ABN6502 SBC R1.

I successfully managed to record and recover data from both my laptop(via external USB soundcard - had a hard time convincing my MacBook an external mic was plugged in) and the tape deck.

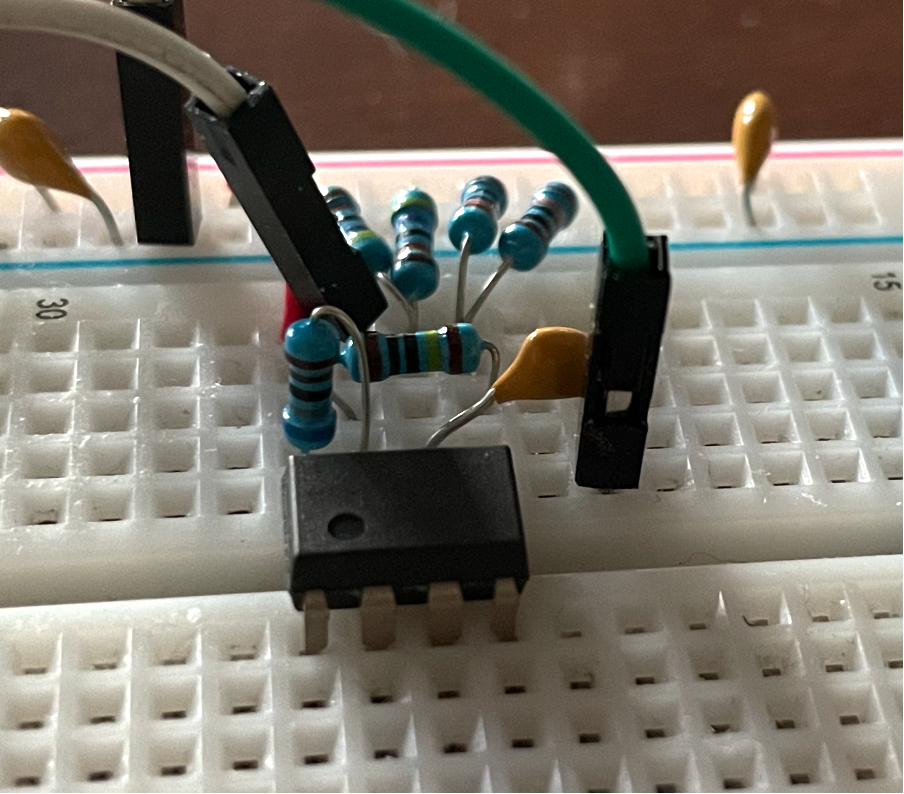

Strangely I had worse luck when recording the video footage than when I did my first tests with the failing tape deck. My best guess so far is that I messed up the voltage divider values for the comparator reference voltage when I went from a LM339(quad) to an LM393(dual) - it should not be at exactly half VCC if I also bias the input at half VCC. Even if I have some hysteresis to prevent rail to rail noise, it won't have a defined state at reset.

I think I can solve that issue by replacing one of the 100k resistors in the ref voltage divider with a 120k - giving a zero crossing reference of 2.7 or 2.3V instead of 2.5V. Either way it shouldn't hurt.My other guess is that the USB-C-hub I threw on my MacBook is noisy when combined with a USB-A external sound card.

For now I'm happy with the design of the PCB itself - even if the resistor values are a bit off. You can expect all the schematics, gerbers, and Kicad files on Github very soon and a video about the whole thing on YouTube, soon-ish..

-

A modem for a 50 year old reel to reel tape deck

07/10/2022 at 21:13 • 0 commentsBeware: There's less about the actual modem in this log and a bit more about restoring an old tape deck! I promise I will get back to the modem another time, after some background info.

Restoring something old can be a joy and a pain all at the same time. Restoring a Sony TC-252W reel to reel tape deck – with the single purpose of using it as 1970’s appropriate data storage for my 6502 computer – has so far been more of a pain but the small joys of getting it in a little bit better condition, working a little bit better, has so far been worth it.

When I first got it, the internal parts were so gunked up it was completely useless for anything but spooling a reel onto another. The tape roller couldn’t even be forced into position.

After a thorough alcohol cleaning of all the old gummed up lubricant and reapplication according to the service manual, it was time to reset all the mechanical adjustment parts.

After having the poor thing opened about 50 times it was finally in a condition where it would play music at almost enjoyable speed … for about 5 minutes before the single motor system would lose the torque needed to keep the speed up.

I had myself convinced it was the various wheels putting too much strain on the motor but after meticulously adjusting every roller – that luckily haven’t dried up – it still had the same issue. Just plain slow after a few minutes of playback.

Until yesterday that is… I was in the middle of preparing to record a video about using it as data storage when… It died. Not even enough torque to start the motor. I could push it into motion with my fingers but it didn’t take much resistance with a finger again to overwhelm it, stop it and lock it up.

Since I’ve already had the motor apart and relubricated it, I know it’s not in bad condition, but after 50 years the capacitors are the usual suspect.

Even though it didn’t have any visible damage or leaks I decided to take out the motor run capacitor. My DMM measured 0 of the 1.5uF capacitance, but in DC resistance mode it measured 93 ohms.. That does not sound right.

The design of the can is 1,5uF + 0,5uF – I’m not exactly sure why it’s arranged like that(with two capacitors inside the same can) but since they are in parallel on the schematic I will take my chances and replace it with a 2uF can of the same physical dimensions, rather than putting an extra can in there.

Thinking about it a bit more I see they are in parallel on the schematic but I suspect the wiring diagram will show the extra 0.5uF are only switched in when the screw switch on the back is set to 50Hz. So 50Hz == 2uF and 60Hz == 1.5uF.

I’m happy I figured that out before I ordered a 1.5uF cap instead of a 2uF. Only downside, I guess, is that this TC-252W will from now on and forever be a European 50Hz tape deck, no matter how the switch on the back is set.

Let's just hope I actually get it running.. 50Hz or otherwise.

Anders Nielsen

Anders Nielsen