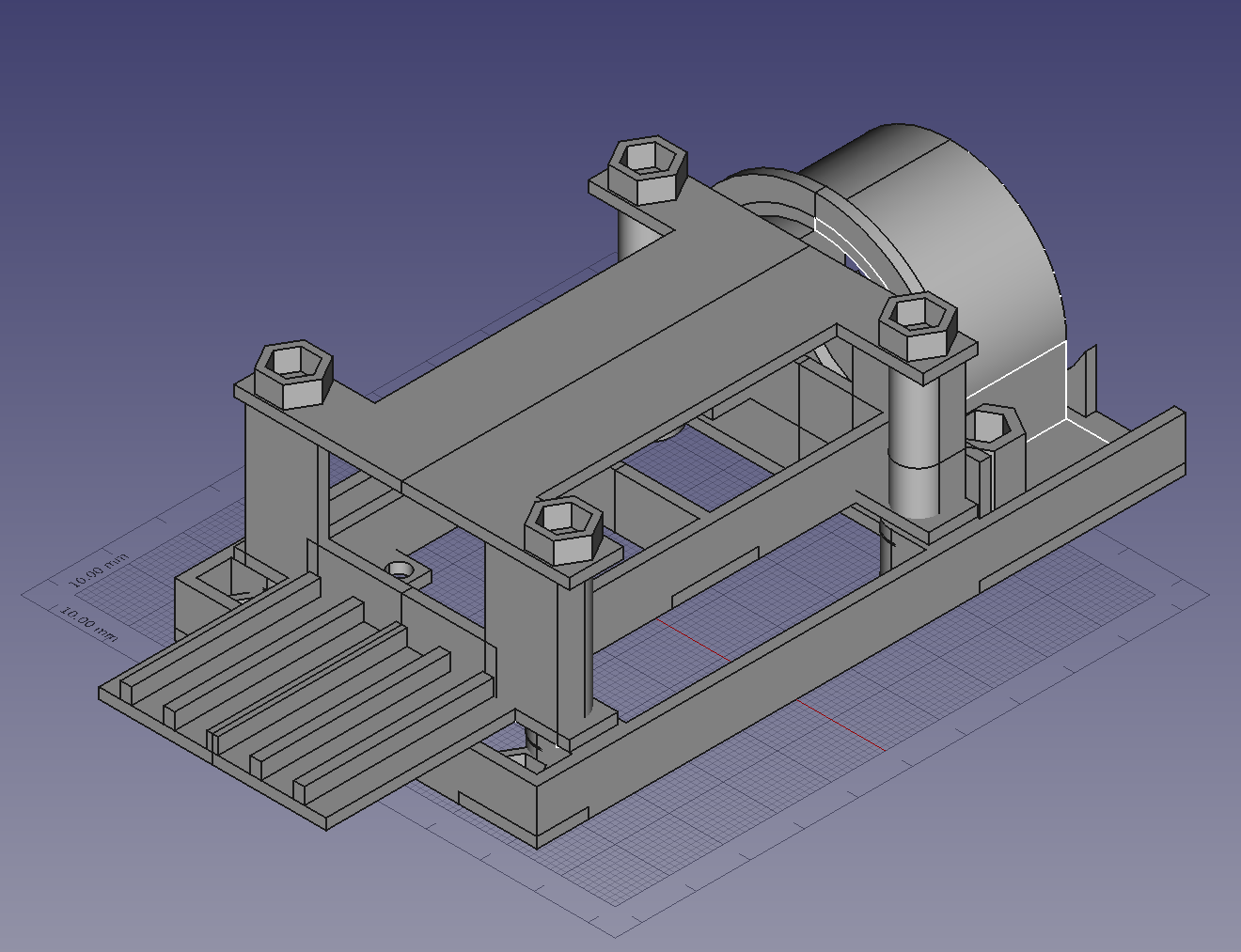

It was always going to be in PETG, printed at 250C. The lion kingdom has settled on 2mm being the thinnest practical wall for PETG & .8mm being the smallest nozzle.

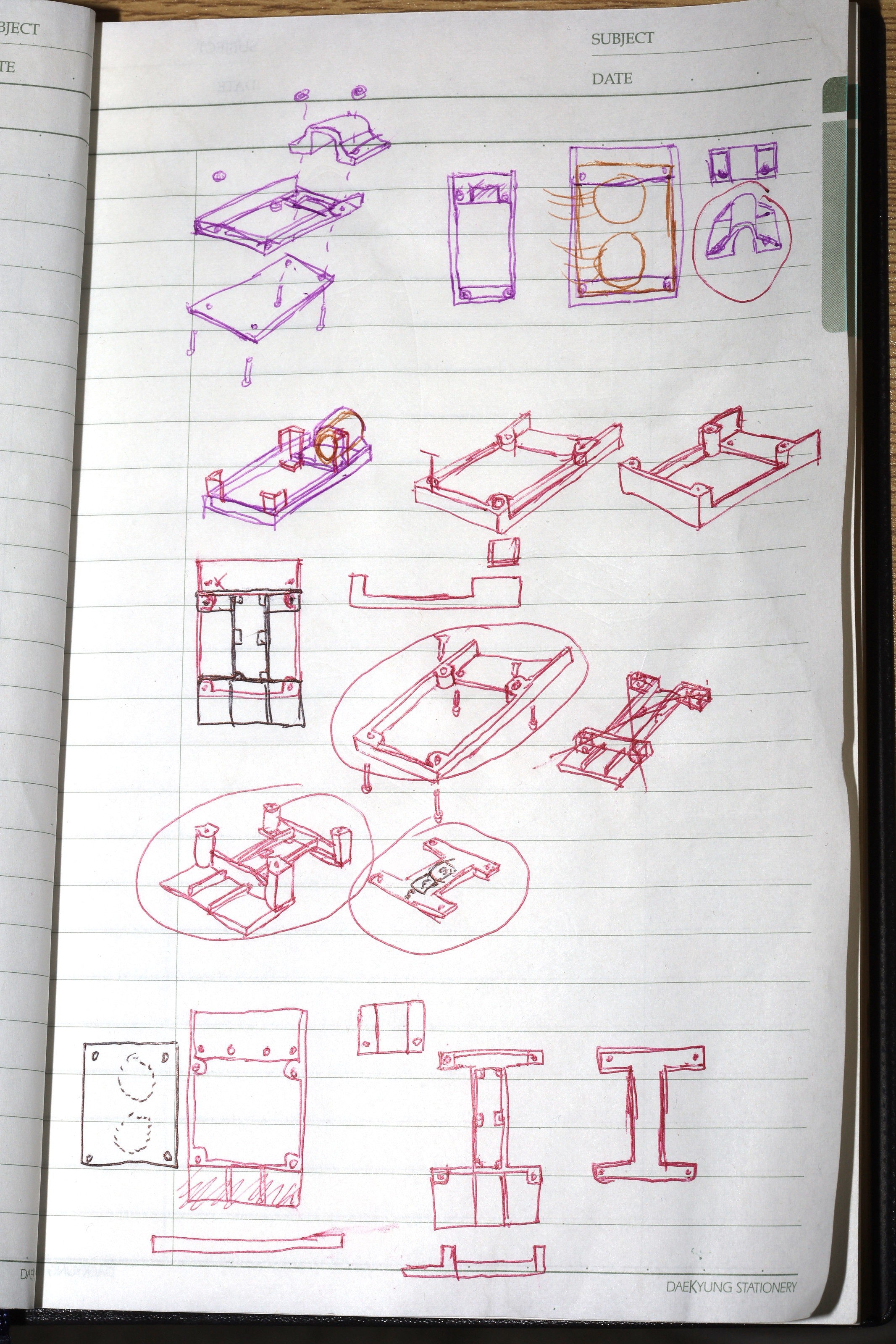

The journey began with many ideas.

It took 2 printouts to finally get a reasonably useful one.

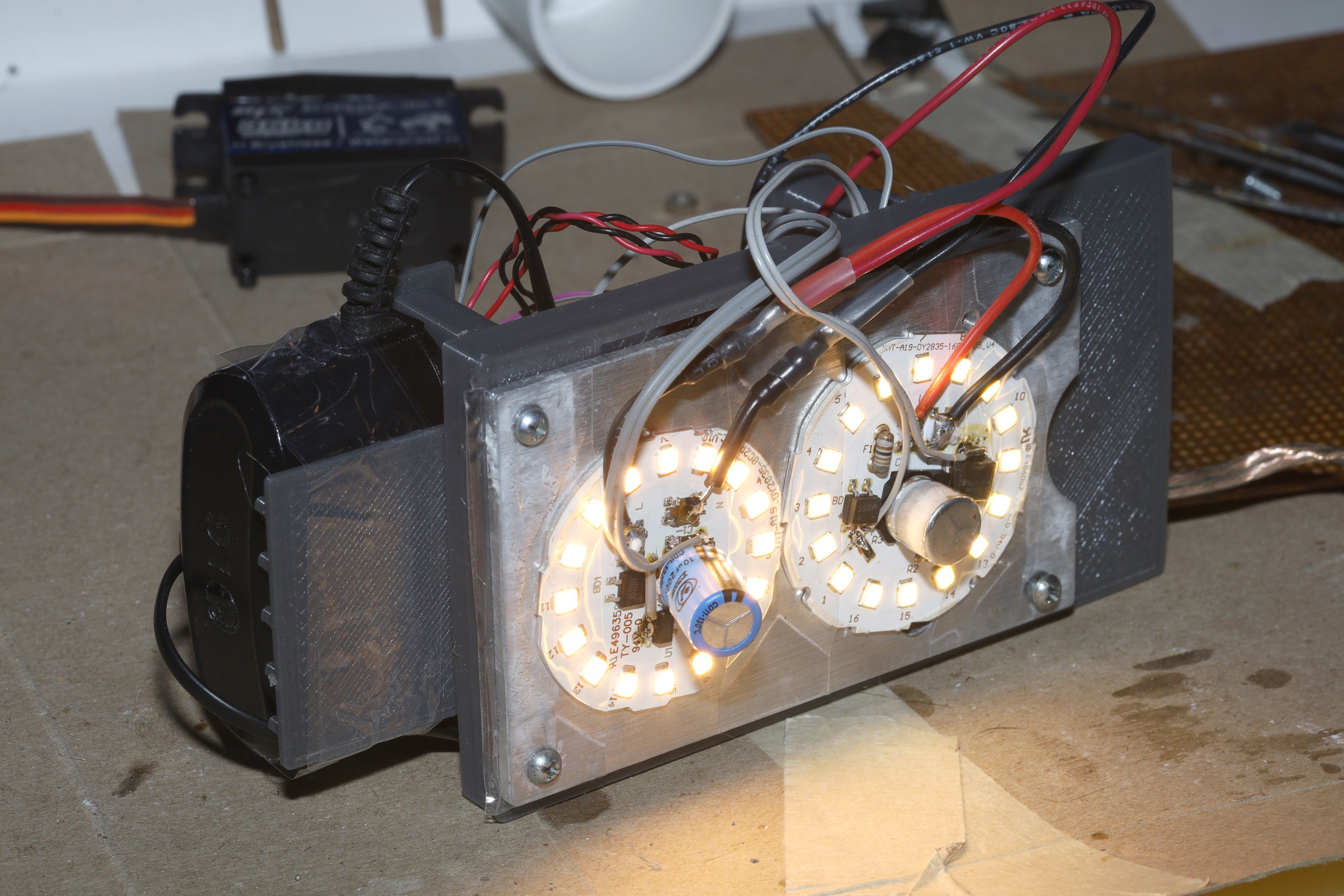

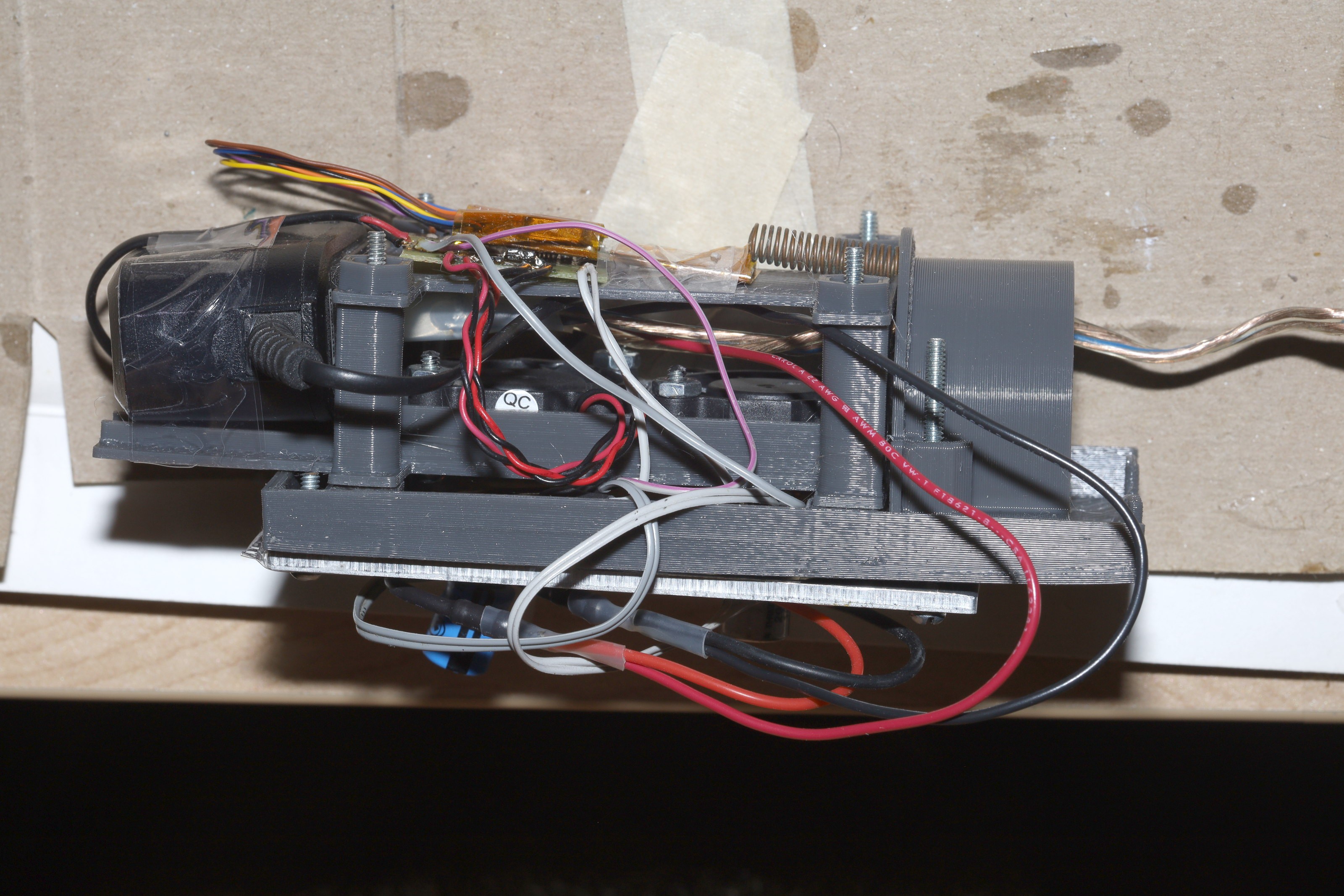

The LED panels ended up scotched on with thermal paste. The heat sink is a 1 of a kind scavenged piece of aluminum. The wiring is a mess. The mane point is as little wiring as possible is covering the LEDs. Logic GND has to be connected to both rectifier grounds or the bulb which isn't connected will flicker. 4 wires have to be soldered to each bulb. There's the manes live & neutral. Then there's the patch from the rectifier GND to the MOSFET. Changing bulbs is going to be a bitch.

A big question is if the fans are doing any good. There's a lot of wiring defeating the airflow. The power MOSFETs flop around on top of the heat sink. The temperature stays between 45-50C on the bench. Power stays in the 8.5W range despite having 2x9W bulbs.

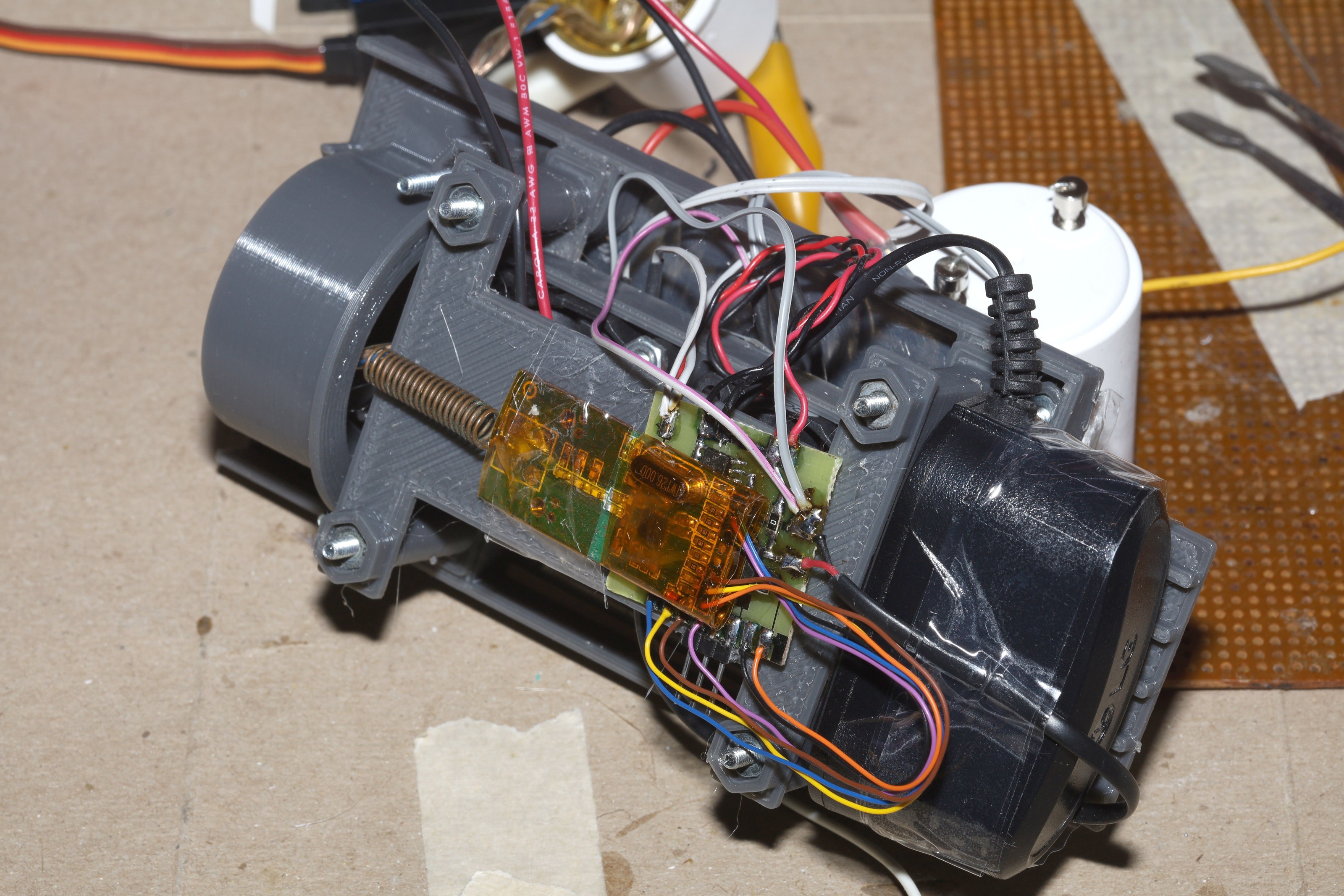

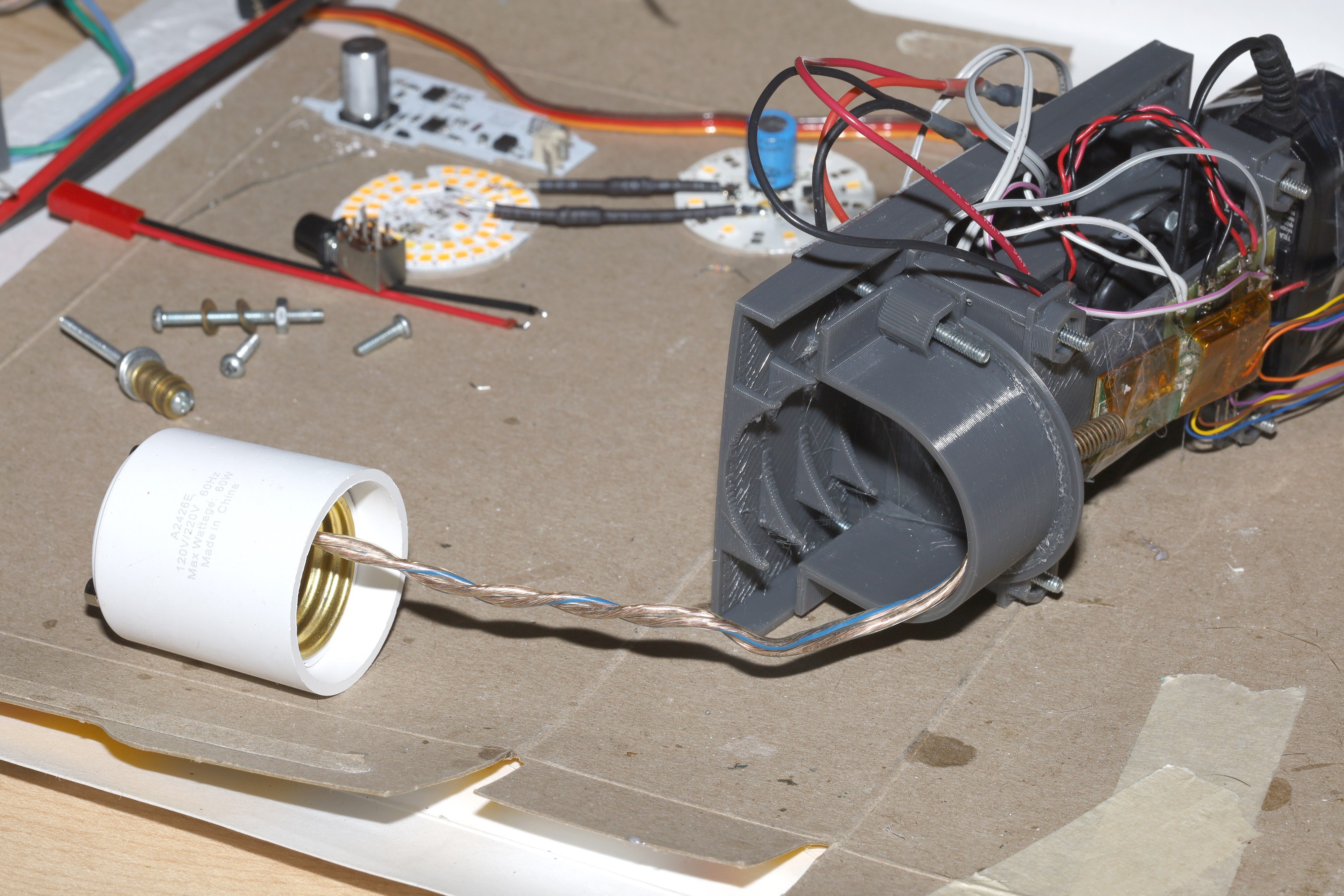

There is an attempt to clamp on to the GU24 adapter. The unsolved problem is farstening the wire to the adapter. It ended up being speaker wire for the manes voltage. It's still unknown if it fits in the enclosure or if there's enough room to slide it on.

A simple remote control was fashioned. It was still not thick enough. The debounce & transmitter timeout were set at 1 second. There's a kind of waiting game to undo a button press. The mane reason for 1 second was so the LED would stay lit long enough to see it. The LED goes out when it stops transmitting.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.