Shipping containers are one of the greatest innovations in shipping and transportation industries. They provide transport efficiency because the transporting items will not be unloaded in transit since they are stacked in a sealed container, have safety because the corrugating sheet metal used for the sides and roof contribute significantly to the container rigidity and stacking strength and have better handling structure on both sea and land. This advantage comes with a price of huge Carbon release to our environment in two major ways,

- the corrugated sides of the shipping container cause aerodynamic drag leading to 10% of fuel loss in road and rail transport generating unnecessary 10% Carbon release to the surrounding

- 90% of world containers are 6.1m long having mass of 2300Kg or 12.3m long having mass of 3750Kg. It is very essential to transport items using shipping containers until it reaches land to be loaded to tracks or train because they are stacked in large quantities but in my well thought opinion, using shipping containers on road and railways in single load or unpiled manner is just unacceptable considering fuel consumption of transporting single 3750Kg or 2300Kg container without adding the weight of transported items inside the containers. Based on the international organization for standardization (ISO), the maximum gross weight for a standard loaded 6.1m and 12.2m containers should be 25000Kg and 30482Kg respectively. The tare weight is about 9.2% and 12% of the gross weight of 6.1m and 12.2m containers respectively which leads to excess consumption of fuel resulting 9.2%-12% Carbon emission

The total unnecessary emission of Carbon because of using shipping containers on road and rail is about 22% out of the total emission of shipping an item from manufacturers to the end user supply.

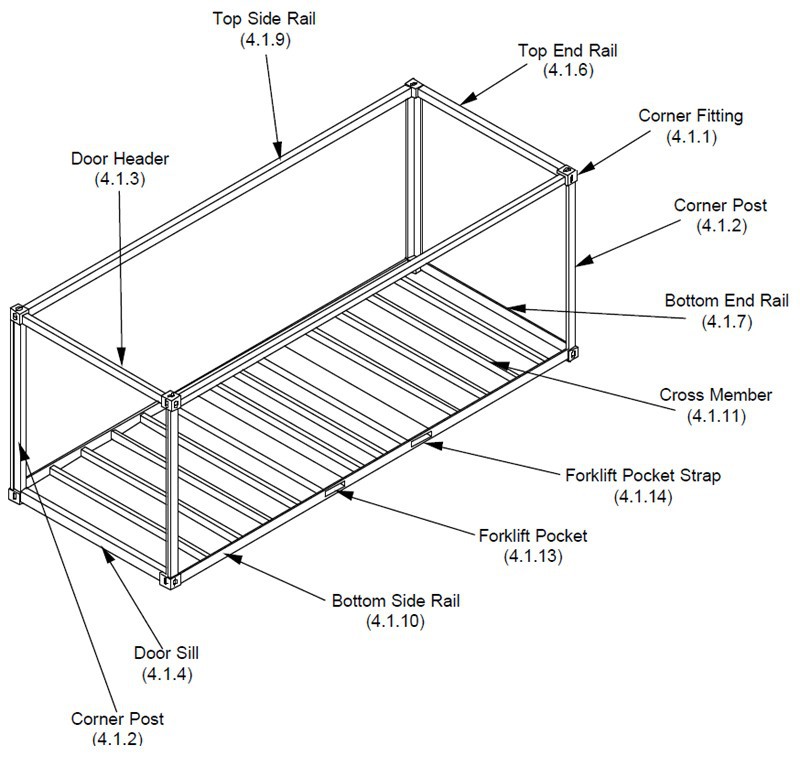

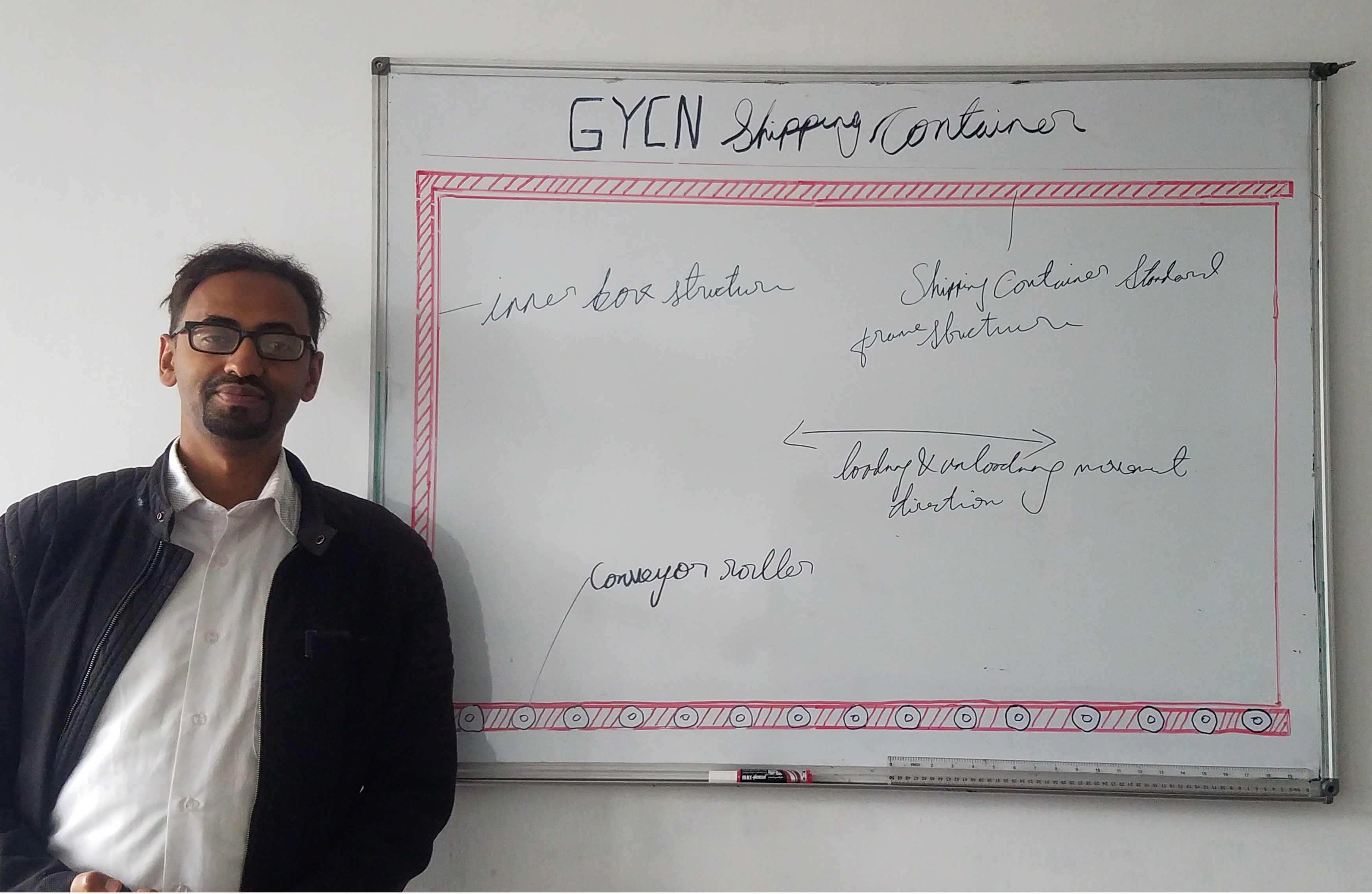

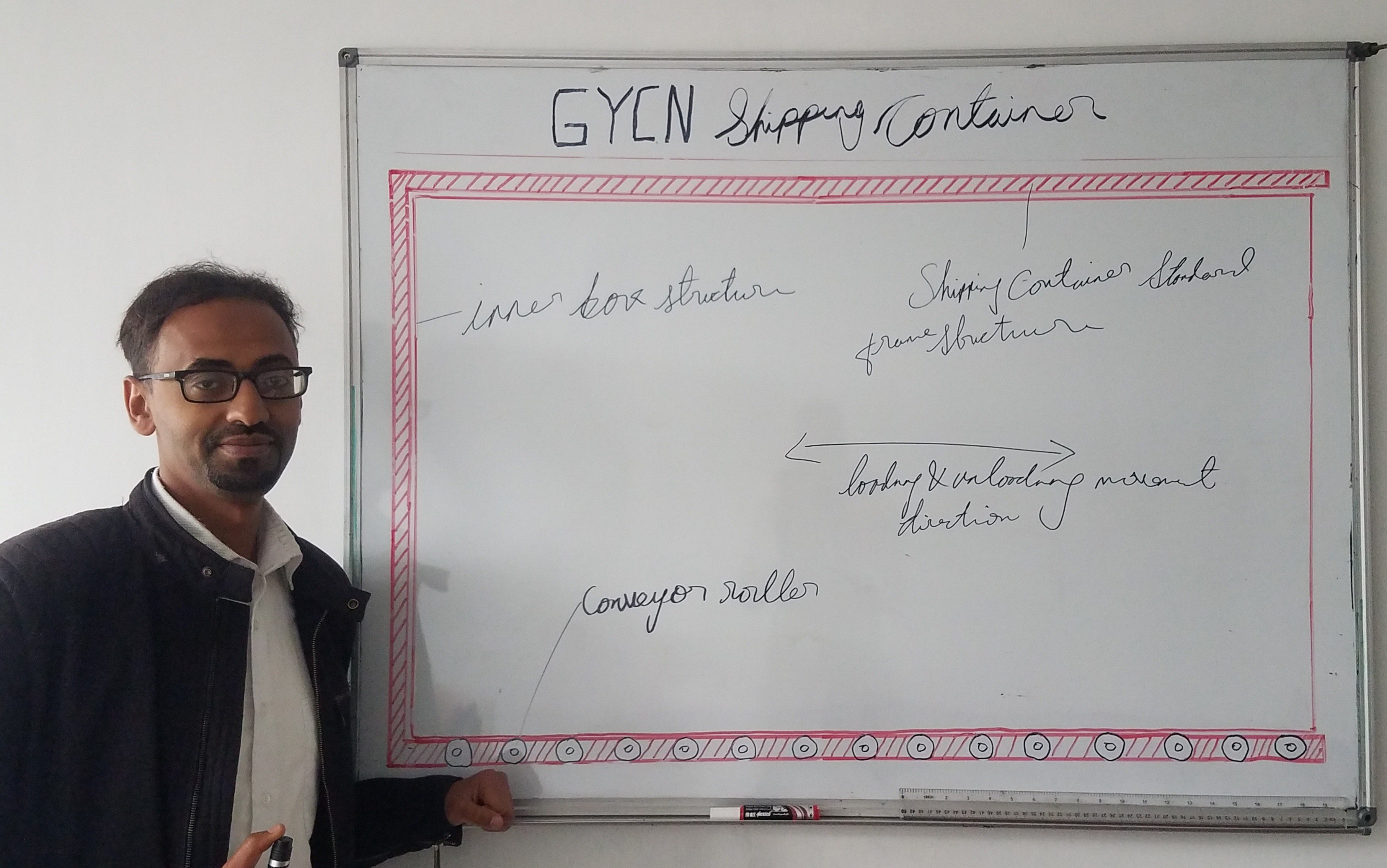

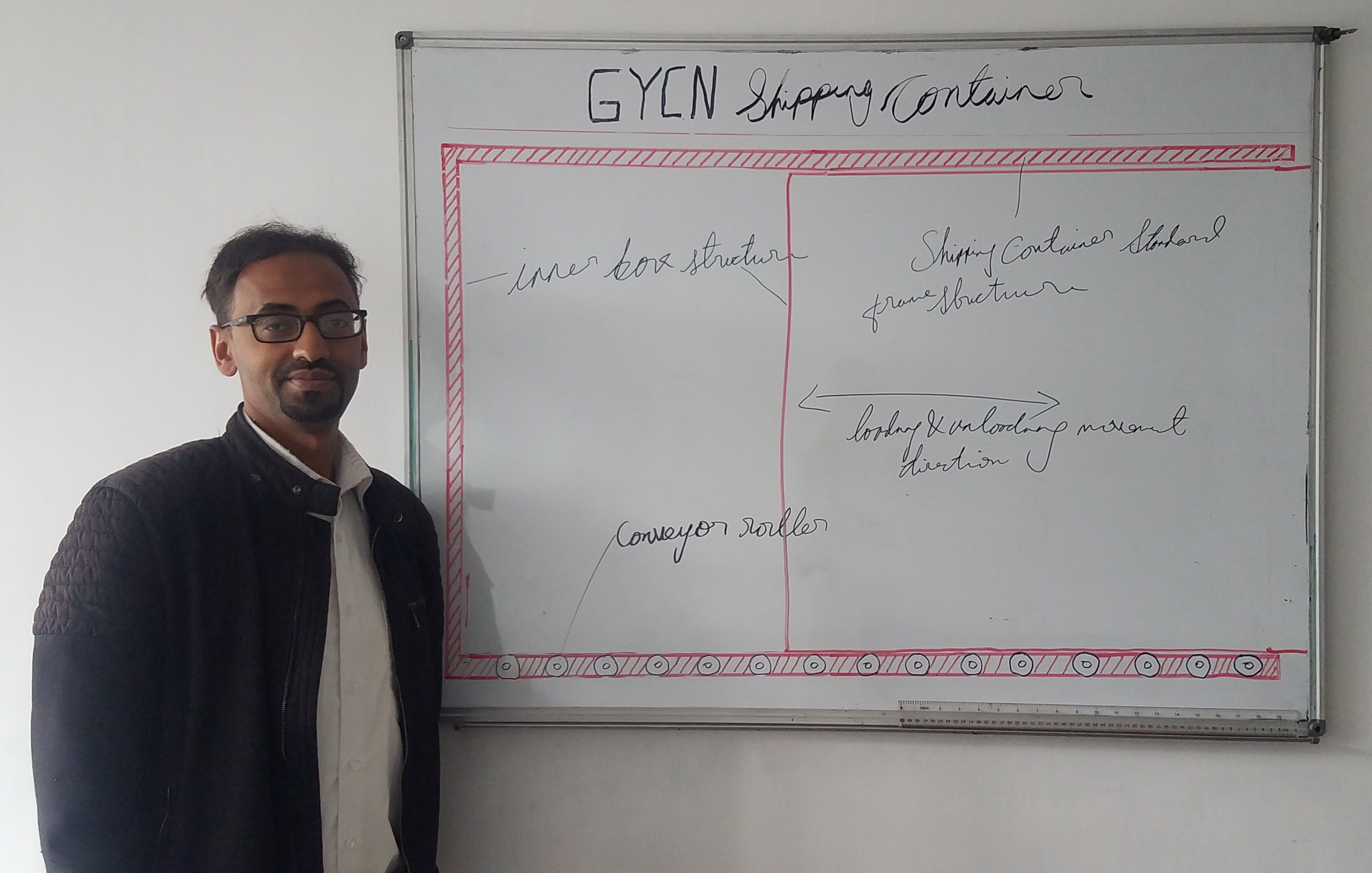

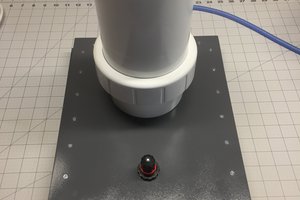

This project is about building a new kind of shipping container that can reduce fuel consumption by 20%-22% during transportation on road and railways reducing Carbon emission by at least 22%. In this new shippi9ng container all the structures and material type are kept the same so that its rigidity and staking strength is maintained but the cross members are replaced with conveyor rollers. On top of the rollers a light weight box having outer layer volume equal to inner layer volume of shipping container is placed. This box is made from light weight material like Aluminum or other type having a sealable mechanism so that transporting materials can be placed inside the box. Assuming that the box have small thickness, there is not much significant reduction of volume and mass increment of the container. As the shipment reaches on the road or rail, the inner box can be pulled out to be loaded in to the truck or the train without having to mobilize the whole container or without having to open the container and unload the items found inside the container. This will enable us maintain efficiency and safety while decreasing Carbon foot print of shipping containers.

One of the major treat the system have is theft because since the box have relatively lower strength on road and rail it will be easier to be targeted for theft but many transport security tech companies provide solutions suitable for this mechanism like utilization of laser to track its sealants combined with IOT that can track in real time or vacuuming the inner sides of the box which are beyond the scope of this project.

Anteneh Gashaw

Anteneh Gashaw

Andrew Mayhall

Andrew Mayhall

MECHANICUS

MECHANICUS