I initially tried to make the cuts with a track and my father in laws circular saw. It kind of worked, but the saw itself kept stopping. I believe I was tripping some kind of internal fuse, it wasn't the house breakers. That's where I stopped for the day.

Then I built a few tables (the two on the right) and bought a decent table saw (the one on the right, the left one isn't up to aluminum). Using these three tables, and my wife's help, I managed to make my first real cut along the 2ft length.

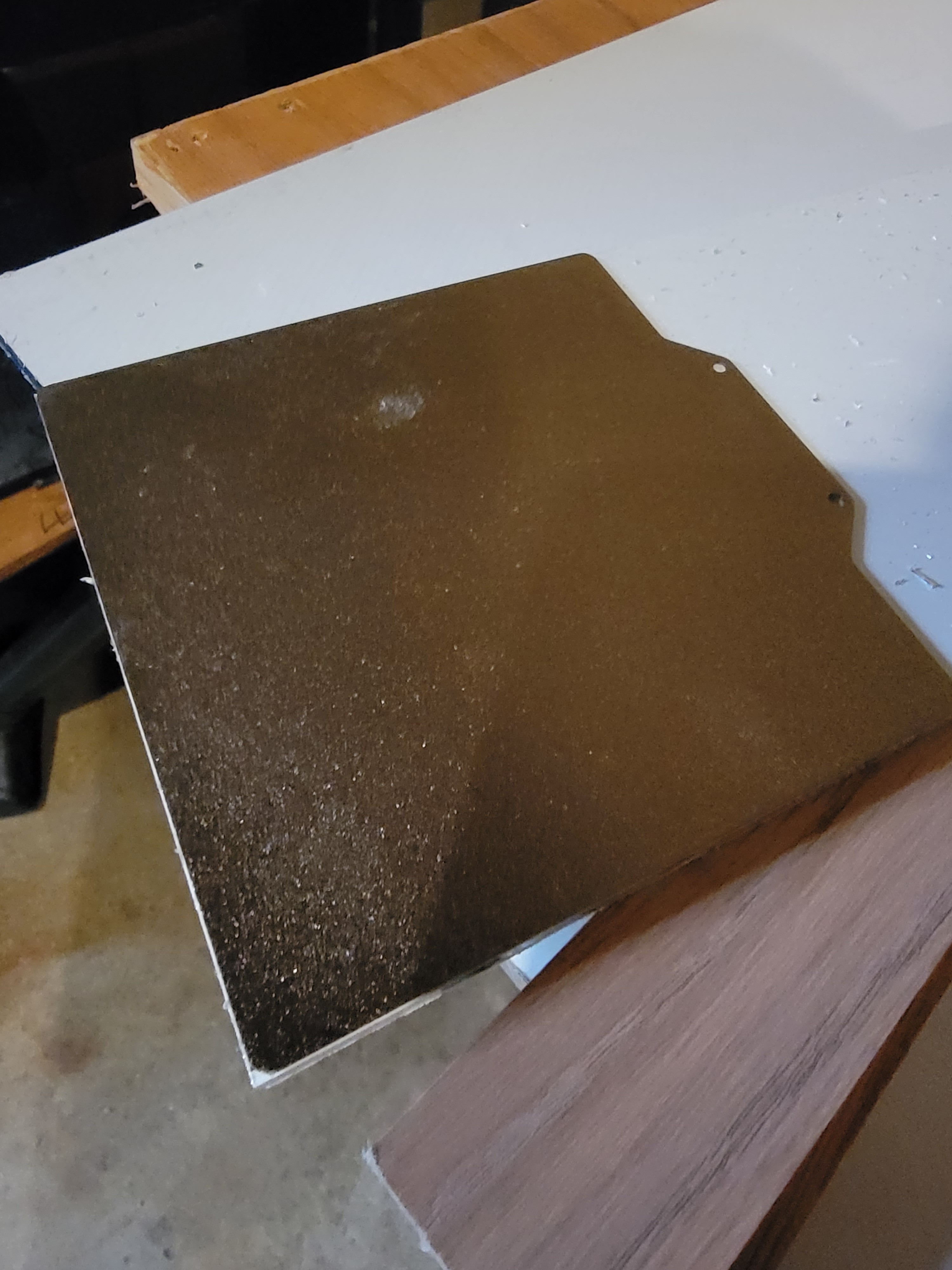

This validated that the table saw itself was up to the task, and the resultant surface quality. I have a plan to make these cuts possible without help, but need to build more stuff.

On the top piece of aluminum, the left edge is as it was from my supplier, the right edge is the one I made.

The picture isn't the best, but I was spot on the right size, apparently!

My updates have slowed somewhat, but that has more to do with wanting to do productive work when I can, so these updates only actually happen when I can't do work for some reason.

Daniel Grace

Daniel Grace

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.