To test our solution with a wider panel of users and makers, we have to quickly facilitate its fabrication.

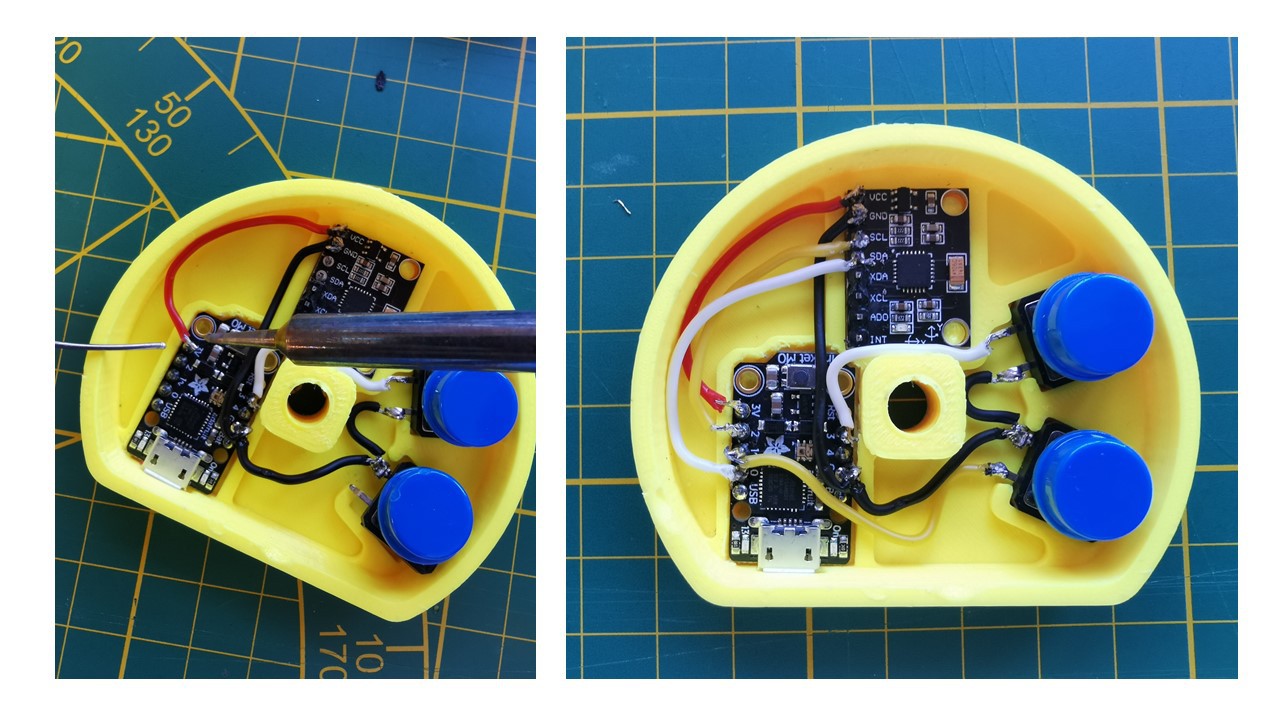

The longest and most error-prone process was electronic assembly, wire and components soldering.

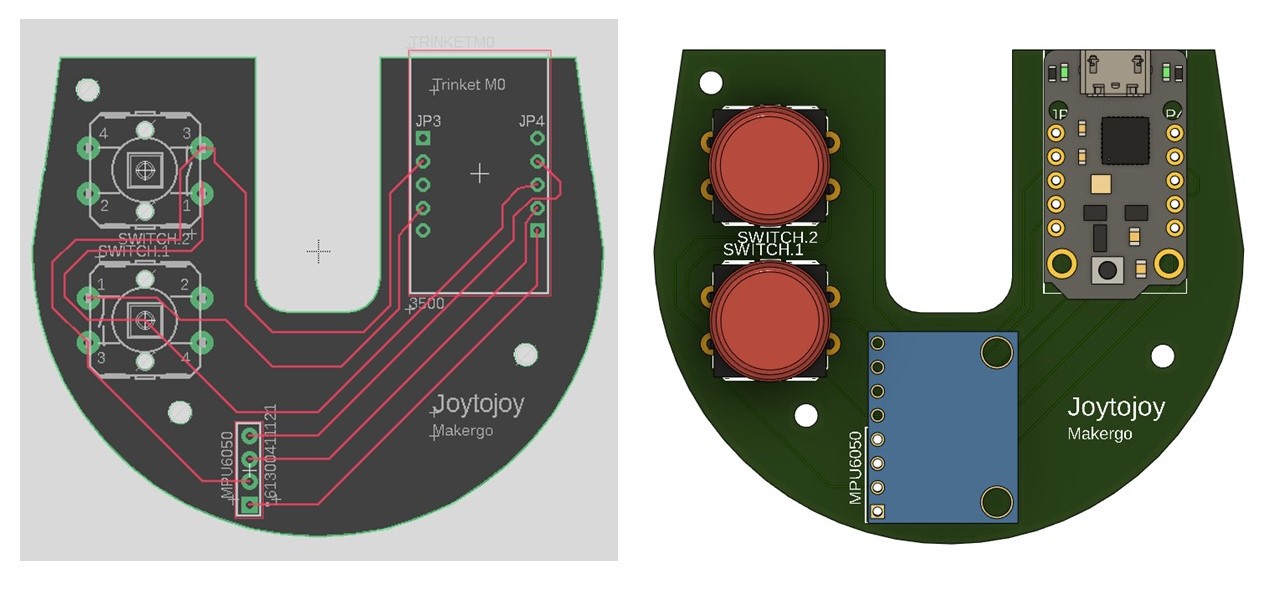

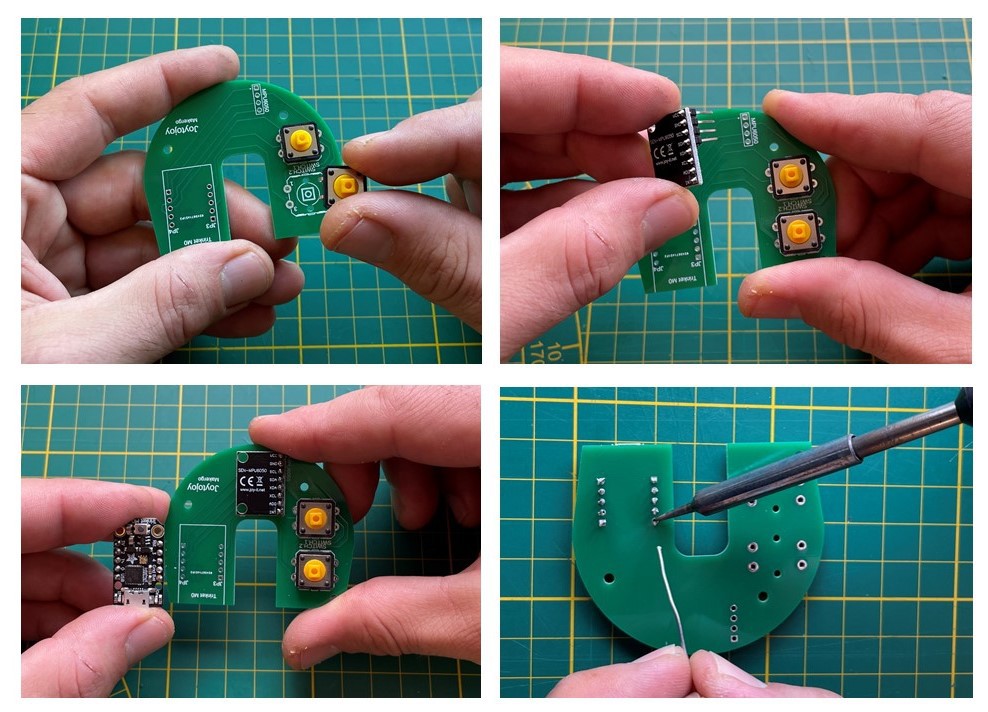

We design a PCB to reduce assembly time and simplify electronic assembly

We adapt the enclosure design, which has grown by a few millimeters, but still remains light and compact.

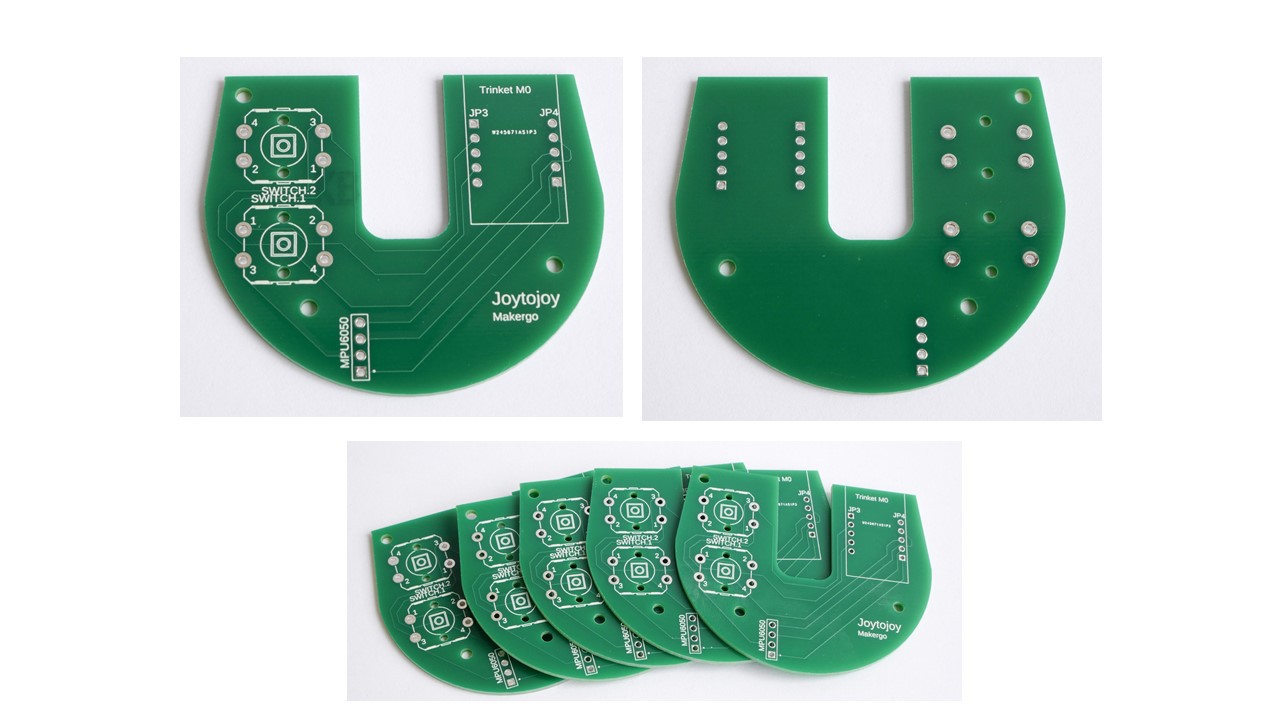

We order a first batch of ten PCBs, and the result is nice

Assembly process is easier and faster (for more details, see instructions)

Users don’t feel any difference in use.

And we can customize it at will

We will soon be able to start tests on a larger scale

Material cost

Our solution have a material cost of 32 $ for one unit.

It's a very affordable stuff for a particular.

Economies of scale can be easily achieved for small series production, especially at the pcb level and round tactile switches.

| Q | Description | Price | Link |

| 1 | ADAFRUIT Trinket M0 | 10,6 | GO TRONIC |

| 1 | Sensor MPU6050 | 3,9 | GO TRONIC |

| 1 | Round Tactile Button Switch Assortment | 7,8 | GOTRONIC |

| 1 | PCB | 6,7 | PCBWAY |

| 1 | 3D printed Enclosure | 3,9 | PRUSA 3D PRICE SIMULATOR |

| Total price | 32,9 |

Julien OUDIN

Julien OUDIN

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.