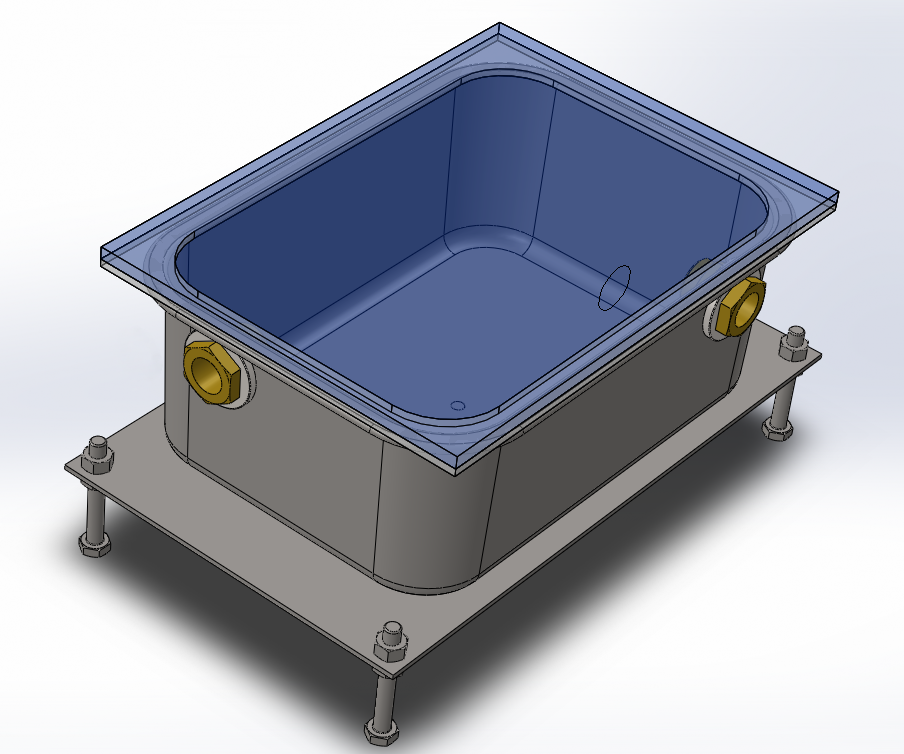

I've finished arranging the parts for the new chamber, and some items have arrived, so I tried to make a rough model.

The 2mm thick base plate and deep tray, the M6 legs are SUS304 (stainless steel), silicon rubber packing and 5mm heat resistant glass are on top.

Brass parts are vacuum exhaust and argon gas supply port.

The point here is the small circle visible in the center of the bottom of the tray.

Spot weld to the base plate only at this point.

The actual thickness of the tray is 0.7mm, so it is expected that the bottom will dent when vacuumed. The motive is to disperse the base plate and deformation stress with this spot welding and endure it.

The flat part of the bottom is roughly 177 x 116 mm, so I wonder if 2 mm of SUS304 will work. (You calculate the strength lol).

The concern is whether the 5mm thick heat-resistant glass will hold up. That being said, I don't want to use quartz glass. . . Please don't break it (You calculate the strength lol).

Koji Tokura

Koji Tokura

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.