Hey folks,

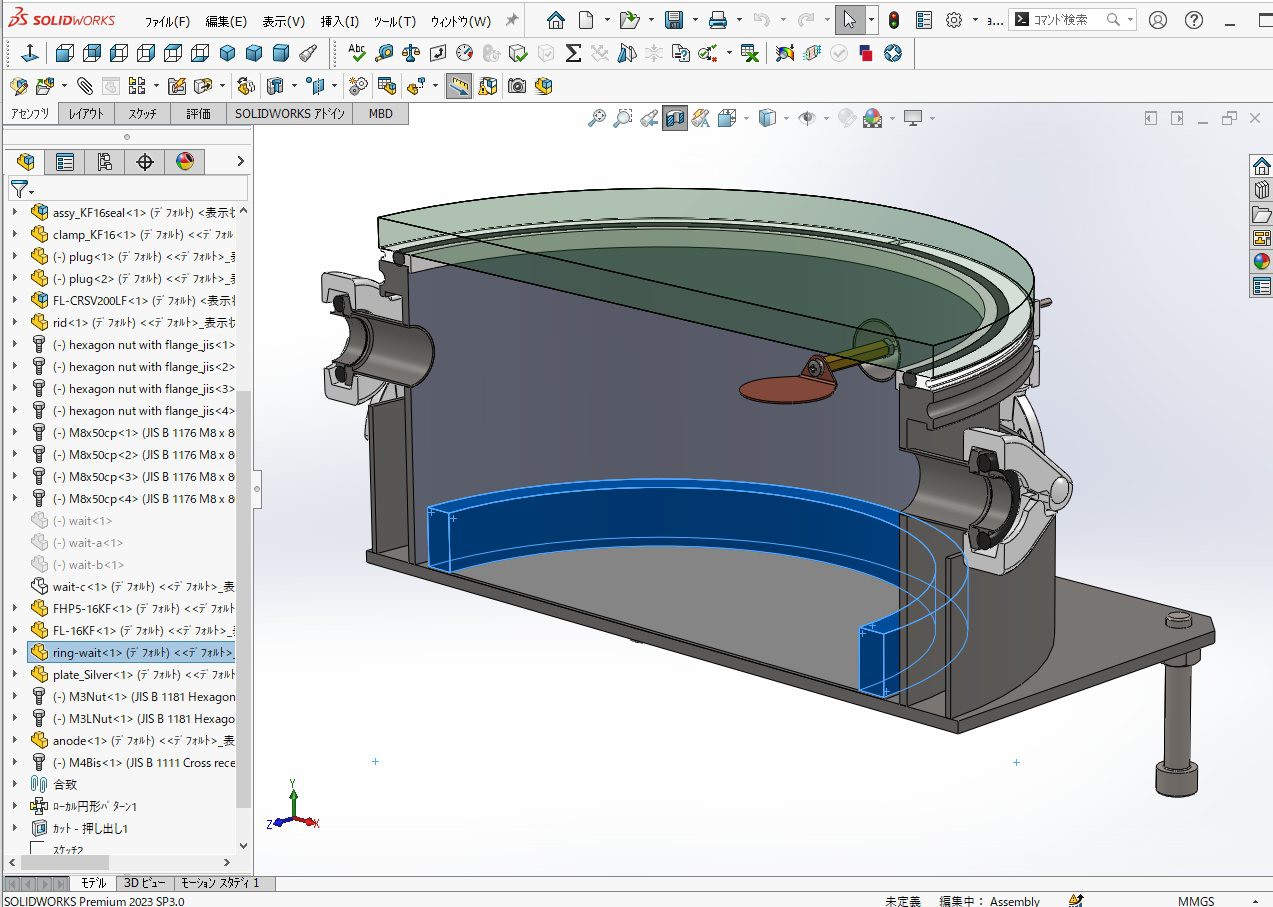

Check out my 4th-gen sputtering chamber.

Back when I started doing DC magnetron sputtering @home, my first two generations of chambers were built around these cute little heat-resistant glass containers I picked up at the dollar store. The base plate was an aluminum slab with an O-ring groove machined into it.

But those setups had issues—persistent arcing and probably poor vacuum levels.

One major problem? I was relying solely on a rotary vane pump for vacuum, which led to oil mist backstreaming into the chamber.

I’m a mechanical engineer, but I jumped into the vacuum world without much background—so I didn’t initially understand some of the weird and wonderful phenomena that happen in high vacuum.

Can you believe it? Even so-called “vacuum-grade” lubricants can evaporate under vacuum, travel a whole meter backwards from the pump, and contaminate your plasma.

Once I figured that out, I finally started reading up on vacuum tech and learned that I needed a turbo molecular pump (TMP)—a beast of a pump.

Check out my third-gen chamber and the TMP startup vibes!

This thing is basically a jet engine. The turbine blades (or whatever they are) spin at near-sonic speeds. You need a backing pump just to get it started, and if you suddenly vent it to atmosphere while it’s running, the blades can explode.

As you might guess, TMPs are insanely precise machines—a new one will set you back around $5000. That’s way out of my hobby budget, so I went hunting for a used one.

And yeah, buying a second-hand jet engine? You can imagine the risks.

But hey, I got lucky on eBay—and now it’s running like a charm.

Alright, so here’s the deal: I’ve finally unleashed the ultimate creation—the 4th-gen chamber. Sourced a vacuum equipment manufacturer on Alibaba, sent over some 3D designs, and had them craft a proper, near-professional-grade vacuum chamber.

Koji Tokura

Koji Tokura

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.