The drivetrain (at least, by my definition) includes the mechanical components which move the skateboard forwards. This is the most important part of the build, and will drive the requirements for the electronics. The drivetrain consists of the following:

- Motor(s)

- Pulley(s)

- Belt(s)

These components structurally and functionally support, or are supported by the following:

- Trucks

- Motor mount(s)

- Wheels

Before exploring my options for each of these, I want to make it clear that I am hoping to reuse as much of the original setup as possible, only swapping out components which would require irreversible modifications. This is for a few reasons: firstly, to preserve the overall look and feel of the board. Secondly, to keep cost down; and thirdly to add some challenge to the build. intuitively this means hopefully reusing the trucks, but not the wheels as they would need modifying. Also, this means I will be using a belt-drive rather than hub motors or direct-drive motors.

Wheels

ESK8 wheels come in a range of shapes and sizes, depending on the use case. They can even resemble tiny bike wheels for mountainboarding! This guide is, as far as I can tell, fully comprehensive and incredibly useful. As I will only be powering one side of the board, I'd like the driven to resemble the existing ones as closely as possible. The current wheels can be defined as follows:

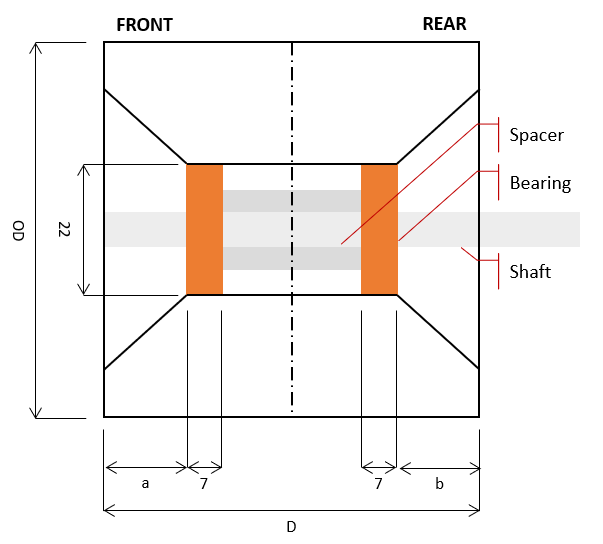

It is important to note however, that a and b are not always the same. Offset wheels (such as my existing ones) and side-set wheels (bearing flush with surface) change the weight distribution across the wheel such that the lateral centreline through the bearings is not coincident with that of the wheel.

| OD (mm) | 70 |

| D (mm) | 51 |

| Hardness | 83a |

| Shape | Conical |

| a - b (mm) | 5mm |

I have toyed with the idea of casting my own hard-cored polyurethane wheels with a 3D printed mould. However, my humble Ender 6 is currently a Frankenstein's monster of r/redneckengineering material due to half-assedly modifying and developing it over the course of the last year. As it currently stands, I don't trust it to produce consistent prints, let alone with more engineering-grade materials which will be safety critical and under significant load. I don't want to have my wheel cores shatter at 20mph downhill! In future I may carry out a project to rectify this.

The closest wheels I can find to these which are commonly available and relatively affordable are the Orangatang Kegel 83a wheels. these have the same hardness and are only 5mm larger in diameter.

Unfortunately they only come in this unnecessarily garish lime green and purple combo which doesn't fit the aesthetic of my board. Therefore I need to look for an alternative.

Unfortunately they only come in this unnecessarily garish lime green and purple combo which doesn't fit the aesthetic of my board. Therefore I need to look for an alternative.

I briefly explored various buy & sell groups, and a selection of different UK/EU ESK8 vendors but struggled to find components. As the ESK8 market is still in infancy, especially outside of the US it seems, most sellers and vendors offer full setups or conversion kits as these appeal to a larger audience. I caved in, and decided to visit AliExpress, where I came across these:

Though not particularly exciting, these wheels match my requirements almost perfectly. They are black, only 8 mm larger in diameter than the stock globe wheels, have a hardness of 80A and have an ABEC style core. They are also very cheap, at only £6.81 per wheel at the time of writing this. I am aware that by limiting the outer diameter of the wheel, which is relatively small in terms of ESK8 wheels, I am trading stability and "momentum" for nimble handling and acceleration - this is driven by the focus on aesthetics. Whether this comes back to bite me or not in future we shall see! I hold some concerns about the quality of the wheel also, as this is an unknown vendor. However, given that I am not planning to use the setup in harsh environments or offroad, these should suffice.

For bearings, I will use the tried and tested Bones Red's that are the standard for almost any skateboard.

Mechanical Architecture

The best place to start would probably be by identifying some requirements. However, figuring out what spec motor to use and building around that seemed more fun so we'll go that route. When I started thinking about the motors, here are some of the questions which came to mind.

- How many motors do I need?

- FWD, RWD or AWD?

- What effect does the voltage have on the overall performance?

- What effect does the current draw have on the overall performance?

- Should I opt for sensored or sensorless motors?

Let's start by figuring out how many motors we need. Most belt-driven ESK8 boards appear to use only one or two motors. Cost is a large driver here - with more motors I will need a larger battery, more ESC's and it will become very expensive very quickly so I will rule out 4WD.

I found this video which provides a good comparison. This thread also has some good information.

Assuming the same battery capacity, 2WD provides more torque than 1WD but not more speed as the two are running in parallel. With a 2WD setup the setup is also balanced in terms of the weight and forward force. This doesn't necessarily matter at lower speeds - with 1WD, a user with skateboarding experience or good balance can counterbalance any drift towards one side but this may prove to be an annoyance. At higher speeds however, this drift would become more pronounced and lead to "speed wobbles".

1WD is technically more efficient than 2WD due to natural inefficiencies in the power delivery route being doubled. This is not significant enough to make a decision on, as I will design the battery to have more capacity than necessary to build in redundancy.

2WD also provides redundancy. If one motor fails, the other can pick up the slack, albeit at a lower speed. The same goes for braking too - if one pulley snaps under hard braking, the other motor can provide braking capacity. For me this is important - I wouldn't want to get halfway through my commute and have to carry a heavy board home, which I would probably have to do as belt-driven setups are known to have significant rolling resistance.

I will settle on 2WD for the above reasons, and also because it provides more scope for upgrading the battery and wheels in future if necessary.

Now I must decide whether to use FWD or RWD.

With motors at the front, you lose traction going uphill as your weight is distributed further back. On the flip side, FWD allows you to go much faster downhill for the opposite reasons. As I plan to use this board for transport rather than speed I would rather the traction (especially with small PU wheels) so RWD is preferred.

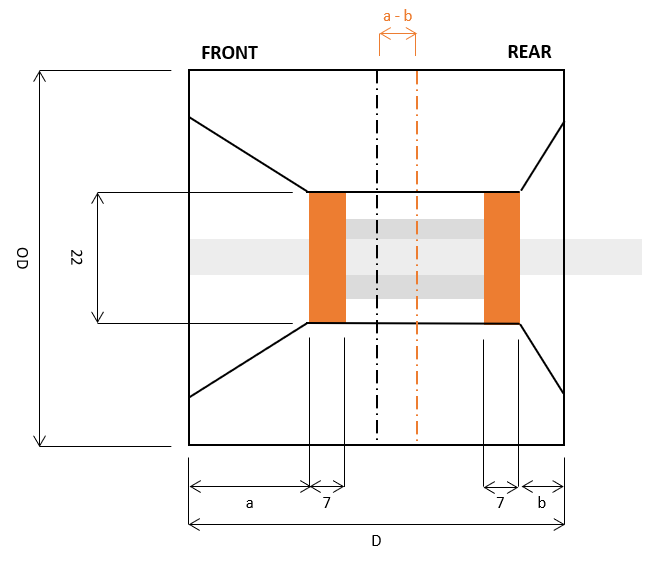

Now I need to decide what configuration the motors will be in.

A and C face the opposite direction to the centre of the board where the electronics will be. This will make cable routing more difficult. Although the range of movement for the trucks would be greater in these configurations, as they will not touch the board during turning, they also expose the motors more and increase the risk of them being damaged. Therefore they can be ruled out.

Option D allows for larger motors, but limits what size wheels can be used. It also exposes the motors, and increases the risk of damage. Therefore, although the motor dimensions will be limited, I will proceed with option B.

After writing this, I realised that options C and D would be invalid regardless, as the pulley would not reach the wheels...

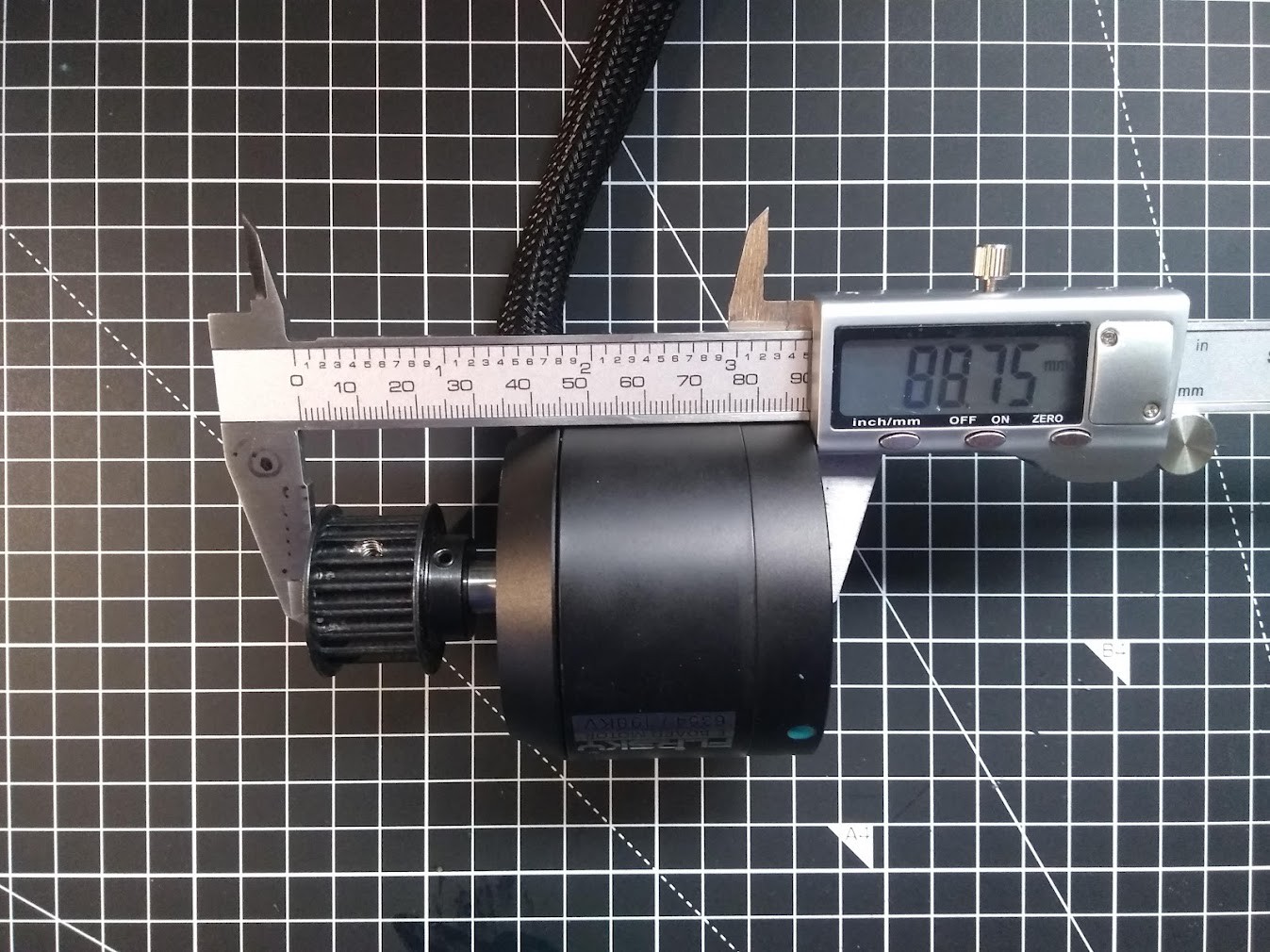

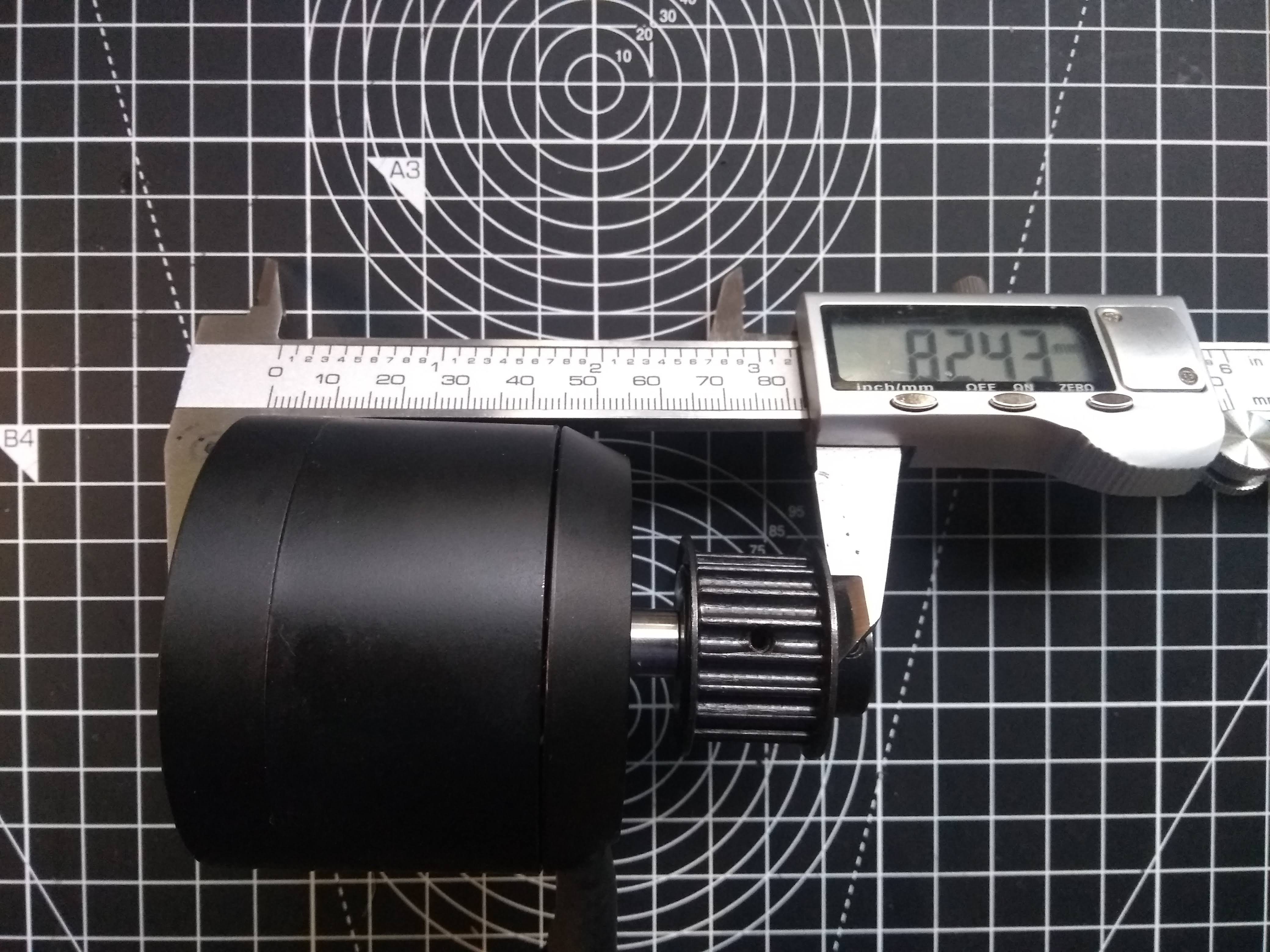

The wheel offset and motor mount position will drive the available motor space. However, as there is no information about the wheel offset within the product description, I have bought the wheels so I can take measurements myself.

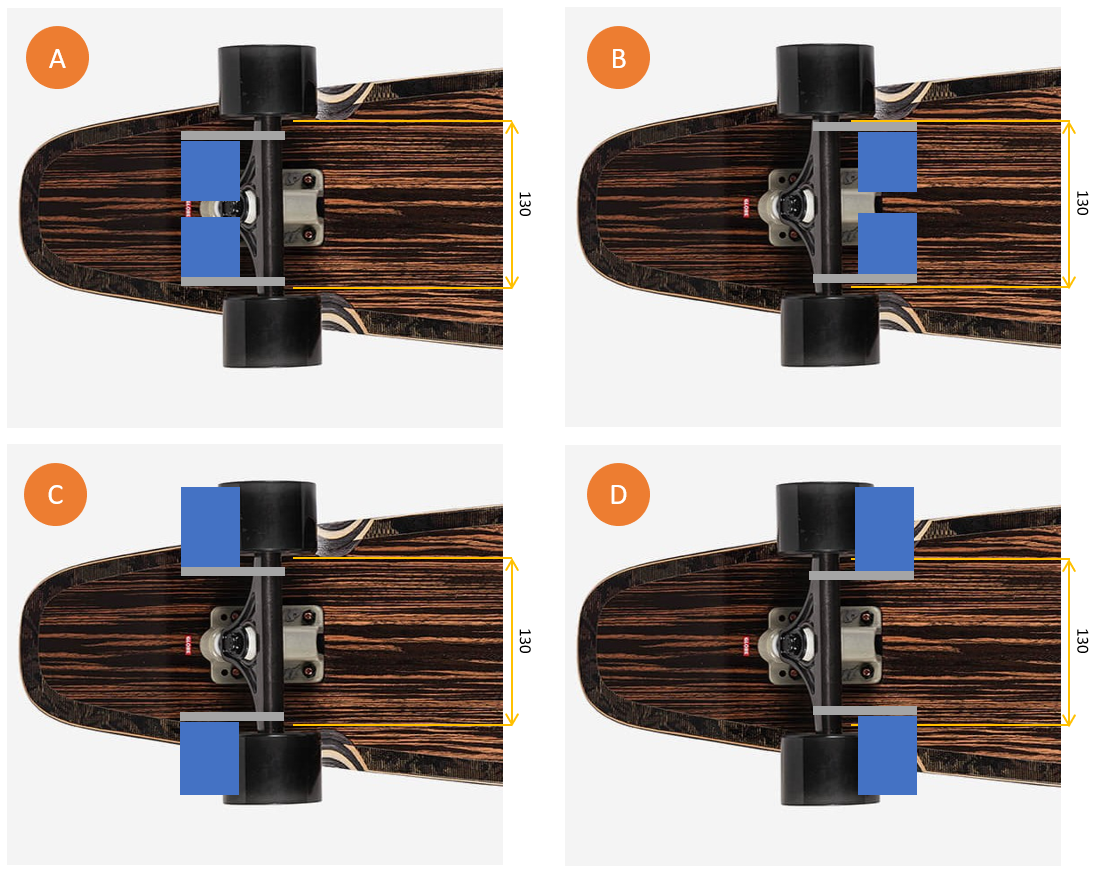

2 days after finding them on Amazon, I assembled them, only to discover the rear offset is even larger.

This is a problem because the motor mount, which I estimate will be about 5mm thick, and belt drive, which I estimate will be about 20-25mm thick including the motor shaft, leaves me with enough room for only 1 motor:

From here, I begun to overcomplicate things:

- Could I cut the wheel laterally to reduce the offset, such that it resembles something closer to a side-set wheel?

- This would reduce the contact area and therefore reduce traction, in a setup already unsuited for ESK8 scale speeds due to the narrow wheelbase.

- Could I design a custom motor mount and pulley system - first prototyping with a 3D printer before committing to machined parts?

- This would be significantly more expensive than just buying ESK8-style trucks and the reliability of the system can not be vouched for without extensive testing.

I tried explaining this whole predicament to my girlfriend, who then proceeded to metaphorically slap me back to reality with how much I am overcomplicating this and how unsafe it could be. My priority is keeping costs down. Hers is making sure I get back from work in one piece.

Much of the lessons learned even up to this point could have been quickly figured out by simply following the advice of the online forums and videos, and trusting the collective knowledge and experiences. However, I have always believed it is much more fun to work these things out for yourself (hence why I'm a mechanical engineer I guess!) and helps you develop a better understanding of the design choices other people have made.

On the plus side, this gives me much more design freedom with less constraints to work around. Let's delve deeper into the motors as this will drive the size of our trucks.

Motors

The best place to start would probably be by identifying some requirements. - Jamie 2022

Let's follow that advice so I don't end up rushing into things again. Here are the main things (in no particular order) to consider:

- Dimensions

- This is exactly what it says on the tin. Electric skateboard motors follow a consistent naming convention to define the external diameter and length.

- For example, a 6368 motor has a 63mm diameter, and is 68mm long.

- Larger diameter motors may reduce the range of motion: on the side where the board leans towards the ground, the motor may contact the underside of the board, preventing the user from turning.

- The length of the motor drives the choice of trucks.

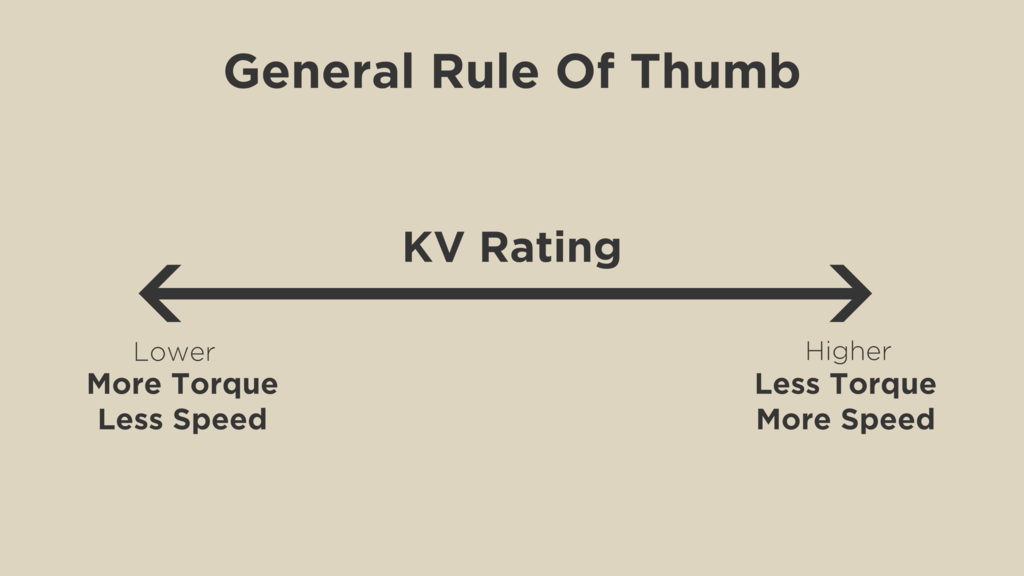

- Kv rating

- Kv (RPM per Volt) is not to be confused with KV (kilovolt).

- For motors of approximately the same shape and size, the rule of thumb is that lower Kv equates to higher torque and lower max speed, in contrast to high Kv which equates to lower torque and higher max speed.

- ESK8 motors will generally range from 140Kv to 220Kv. This video by MBoards states that the "sweet spot" is between 180-200Kv for a good balance of torque and speed.

Maximum current draw

Maximum current draw

- Beefy motors are more power hungry and will require higher current-rated components to avoid causing damage to the electronics. This may be avoided by using a current-limiting VESC but this is a topic I will delve more into later.

- Typically this value will range from 50 - 100A.

- Running the motors at high speeds or up steep inclines for an extended period of time will draw lots of current, and therefore drain the battery very quickly. It will also make everything much hotter which could damage other electrical components.

- Maximum voltage input

- This linearly relates to the maximum speed of the motor.

- Imagine you have a 200Kv motor running at 10S (36V). It is attached to 70mm wheels via a 2:1 pulley reduction. Assuming the system is 80% efficient, this gives you a top speed of approximately 24mph.

- The same setup, running at half the input voltage, 5S (18V) has a top speed of approximately 12mph

- You can use this calculator to estimate your top speed as I have done.

![The Music Telegraph] Ohm`s Law](http://www.themusictelegraph.com/imgdata/themusictelegraph_com/201901/2019012940453364.png)

- Sensored or sensorless

- Sensored motors use hall effect sensors within the motor housing to determine the internal rotor position, which is fed back to the ESC and allows a "smooth start" from standstill. This is particularly useful for boards where the user is strapped in (i.e. mountainboarding).

- Sensored motors provide extra data and customizability to the setup, at the cost of increasing complexity, reliability and price.

- Sensors will add potential failure points to the system. For example, if the sensor comes loose or is damaged during riding, it may prevent the motor from working. If this occurs suddenly it could be dangerous to the rider.

- Sensorless motors are just like me - simple. They take a power input, and spin. No fancy data, no added complexity. They are cheaper and more reliable.

- However, sensorless motors may not be suitable for more casual riders who have no prior skateboarding experience, or struggle with their balance and want to start from standstill.

- With sensorless motors it is advised to push-off to get them moving, otherwise they may get damaged, or provide a sudden change in momentum which leaves the rider writhing in agony on the pavement.

Cost is one of the largest drivers of this project, therefore my decision on which motors to use will ultimately boil down to the price/performance ratio. However, as my board will mostly be used for cruising on smooth, paved surfaces without too many hills, I know to look at the less expensive end of the market.

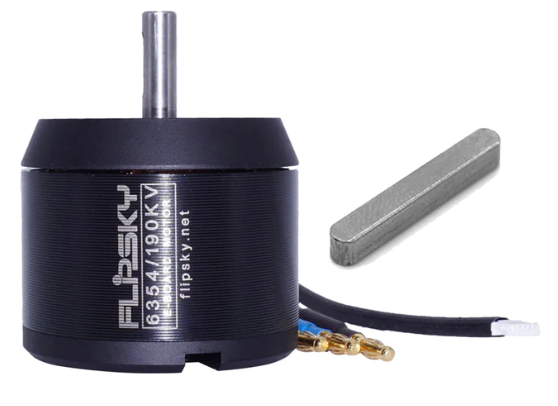

Having compared a few different options, I decided on this absolute beast of a device:

The Flipsky 6354 BLDC motor has the following specs:

The Flipsky 6354 BLDC motor has the following specs: | Specification | Value |

|---|---|

| Diameter | 63mm |

| Length | 54mm |

| Kv Rating | 190Kv |

| Maximum Current Draw | 65A |

| Maximum Voltage Input | 12S ( ~ 43V) |

| Sensors | Hall Effect |

Not only does this motor pack an absolute punch for its size and price, but it is also "battle hardened" which is marketing speak for enclosed, to prevent debris from damaging it during operation, and can run in sensorless mode.

Not only does this motor pack an absolute punch for its size and price, but it is also "battle hardened" which is marketing speak for enclosed, to prevent debris from damaging it during operation, and can run in sensorless mode.

I was slightly trigger-happy and accidentally ordered the default 15mm belt, 16T pulley with it. I see this as a positive as it is probably cheaper than buying a pulley separately, and means I have less decisions to make.

On a side-note, I had actually written a much more comprehensive guide for this section, including an in-depth justification of my motor choice. But, in clearing my browser cookies I also cleared 2 hours of progress in this log... Besides, if you're looking to build an electric skateboard of your own, you can gather more accurate and concise information by scouring more experienced ESK8 forums and guides than from here.

Trucks

With the current motor and pulley combo, the hanger width will need to be approximately 210mm or more.

I decided to visit some ESK8 forums to see what trucks other people have used with a dual Flipsky 6354 setup. As with most electric skateboard builds, the Caliber II's seem to be the most common trucks. This is for a few reasons:

- They have a squared-off hanger profile, which makes them ideal for mounting motors to.

- They are reverse kingpin trucks, which makes them stable at higher speeds.

- They are relatively inexpensive.

So, I went online to buy some Caliber trucks. Thankfully, they are not difficult to find and there is a huge variety of different colours and configurations. However, I couldn't seem to find any with a hanger width greater than 184mm. As my wheels have a 15mm offset, it would be impossible to use these.

How on earth are people building their electric skateboards with dual 6354 motors and Caliber II's if the hanger isn't wide enough?

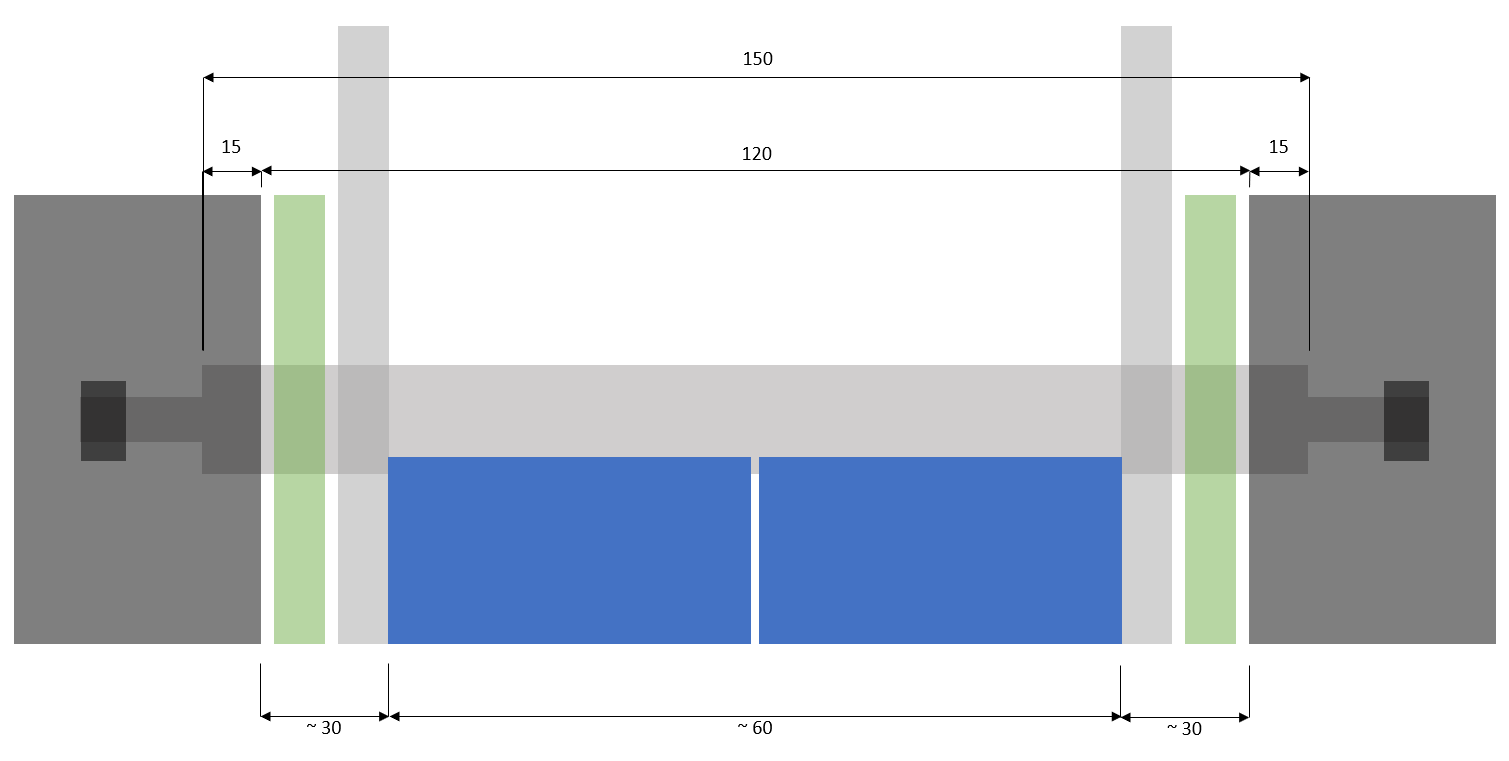

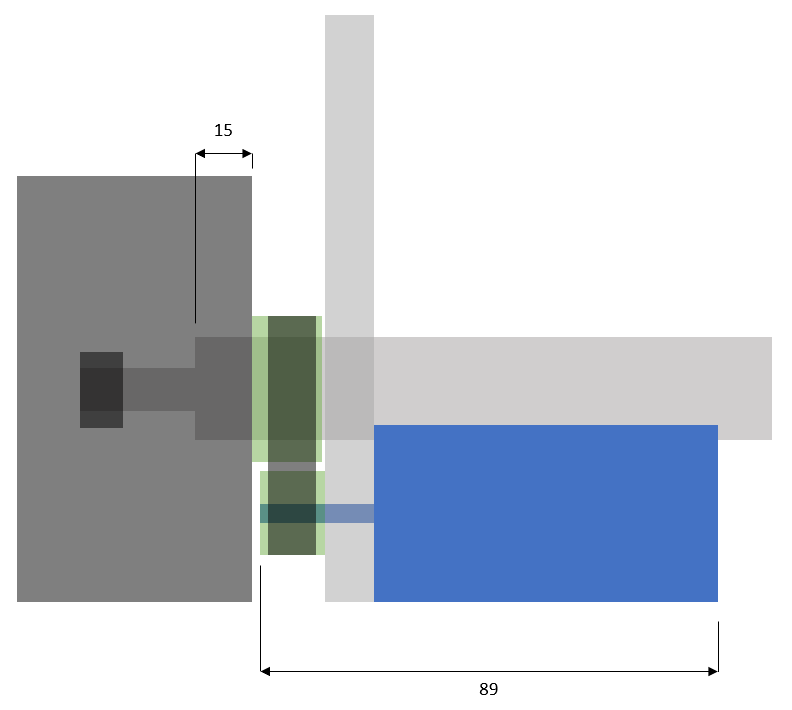

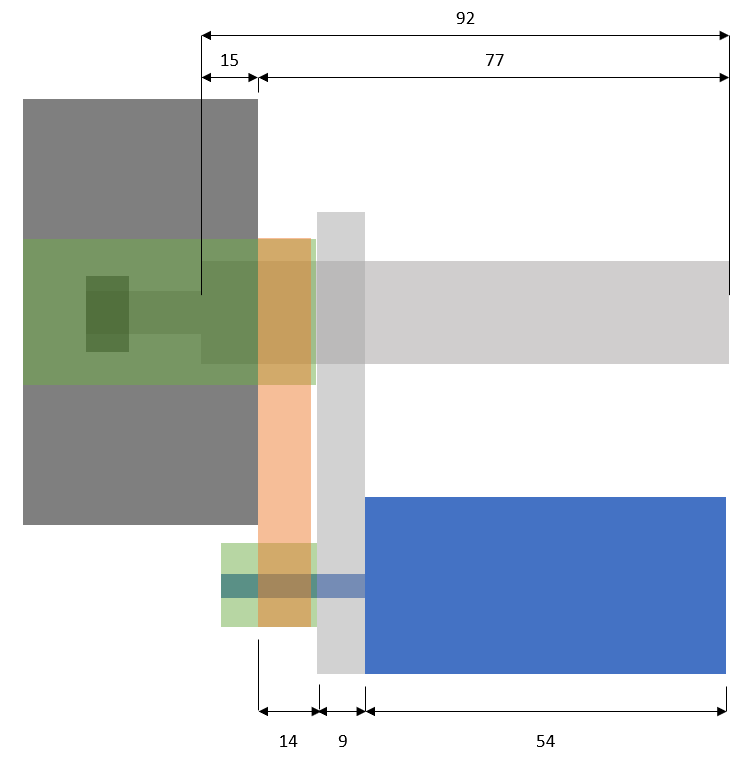

Firstly I flipped the pulley. This saves 7mm:

I then created a diagram to build a better understanding of how everything will be assembled:

It is clear now that with the Caliber II's, I would have about 14mm (give or take 1mm, my measurements were rough) for the belt. Although this means I cannot use 15mm wide belts as the pulley is designed to, I should be able to get away with 12mm belts or similar widths.

It is clear now that with the Caliber II's, I would have about 14mm (give or take 1mm, my measurements were rough) for the belt. Although this means I cannot use 15mm wide belts as the pulley is designed to, I should be able to get away with 12mm belts or similar widths. So now it has been validated that the hanger width is sufficient, I need to decide which variant of the trucks I will use. For this, I need to understand a few things about longboard trucks.

From raked vs unraked hangers, to 44° vs 50° baseplates, to ball vs cylindrical pivot points, and more: there is a huge range of parameters to decide between. This guide does a fantastic at explaining them all.

I am going for raked trucks, rather than unraked trucks, as I can experiment with positive or negative rake. Rake is a difficult concept to grasp, but essentially, negative rake provides a more linear turn, which makes it predictable and less "carvy". It also lowers the ride height, which could potentially cause the motors to touch the board prematurely and prevent tighter turns, but this can be solved with riser pads. Positive rake provides a "diving" feel as you lean into a turn, making the board more manoeuvrable.

Jamie

Jamie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I like your writing style. Keep up the good work.

Are you sure? yes | no

Thank you, it means a lot to hear that. I am trying to document it with authenticity so people can see that it's not such a straightforward experience and there's certainly a learning curve!

Are you sure? yes | no