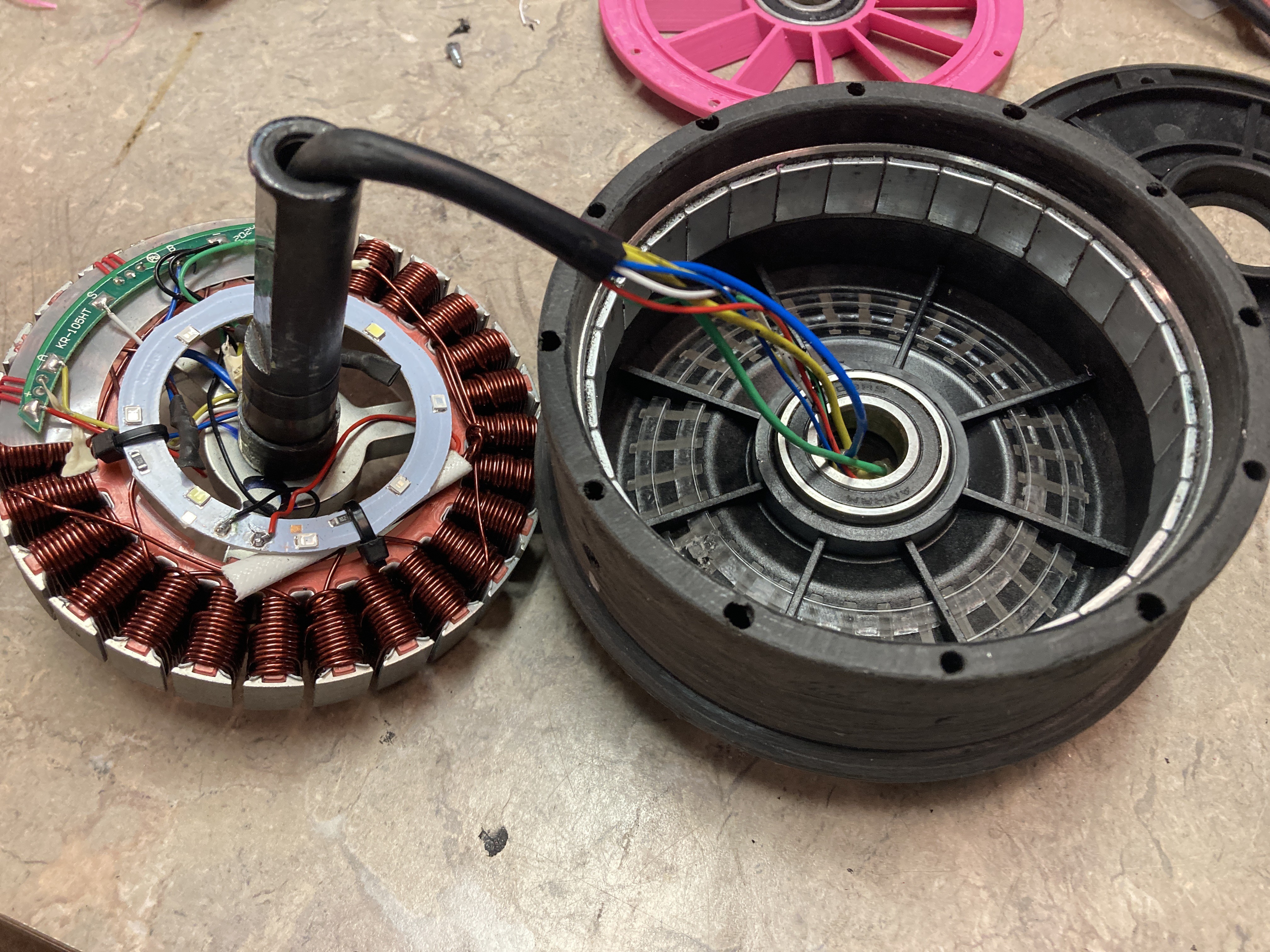

Original configuration on the right new configuration on the left.

The shaft ends have been swapped, by swapping the bearings and drilling a hole to allow for flipping the shaft out the pretty side.

The wheel lights were relocated from the far side of the armature to the near so they can shine out the shaft side now. They are powered from the hall effect sensors (as per original design), which also means I can't turn them off without adding a wire. Not adding a wire.

Every other screw hole on the original hub was drilled straight through. The hub was flipped and the new pilot holes were used to make some countersunk screw holes. Then every other hole was drilled to full screw depth to accept the screws without distorting the hub.

The result is that I now can join the halves together with great force by using 12, 3in drywall screws. This is good because at 40psi, the two halves of my hub are being pulled apart with 800lbs of force.

A valve stem has been epoxied in and ported out to a reasonable spot.

I drilled straight through from the outside parallel to the surface until I breached the rim area. This angle avoids any conflict internally with the armature, lights, or windings.

This was expanded to intersect the screw holes, the breach was sealed with epoxy, and a new hole was drilled at an appropriate depth from the rim.

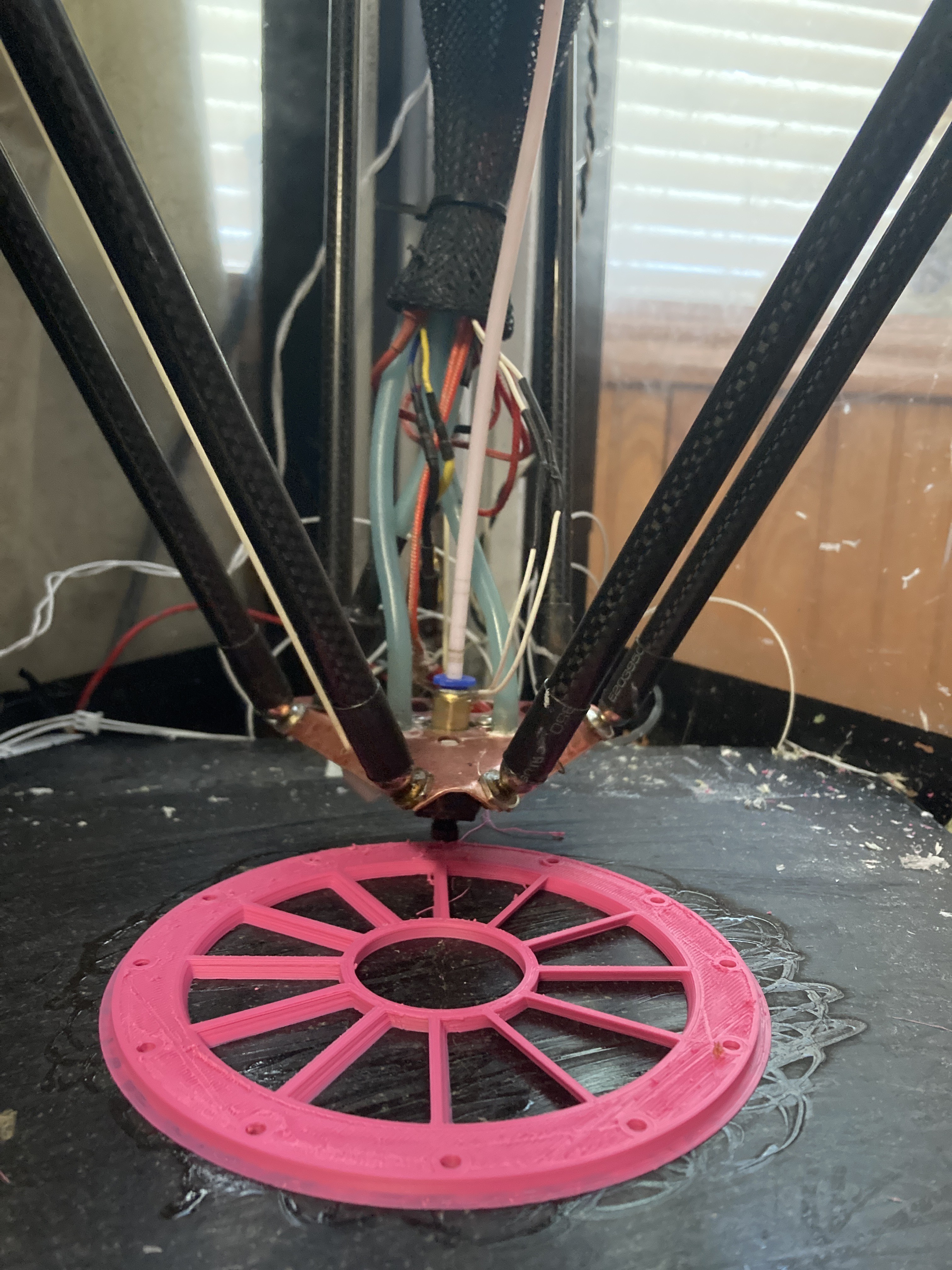

Winning version of the hub end cap replacement, designed in OpenSCAD.

The thickness puts the outer bearing just engaging the centering spring when flush with the outer surface. This allows me to screw them together, face to face, inside the tire.

I plan on bonding them more or less permanently to the hubs with ABS pipe cement. The chosen dimensions are a friction fit for the hub and for the bearing after light sanding.

You can see the hexagonal groove designed to fit an o-ring to seal the two halves when assembled.

Sealing the two halves needs to happen inside the tire, so other solutions (v grooves on hub parts and loads of black RTV) have proven *inconvenient*.

Models will be up when I'm done, or when I get nervous enough to push the project.

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.