Made a nice battery mount. Gives my lights some more clearance and a better spot to mount. Heat bent some poly carbonate. This is actually really, really simple. Draw a line on the material, and then heat with a micro-torch right on the line, on both sides, with a little more time spent in the middle. If you start to get bubbles, you are too hot or concentrated. Five minutes later, bend against something hard.

It is intentionally over sprung a bit to be pulled into tension when the batteries are mounted.

I removed the front crossbeam and replaced it with a smaller one. The headlight was not fitting nicely with the old one as it is mounted at a 15 degree angle and takes up the full height of the deck.

I sized the rim on my 6in wide tire. I had a 4in wide before, but I didn't like it. The bead area on the tires is about 1/8th in too small in diameter to fit the hubs straight away. Careful grinding with a sanding disc on the angle grinder brought it to the right size. This grinding was pure art honestly. The rubber turned in to rubber cement as it was ground and so this was a sticky blind cutting mess that came out beautifully.

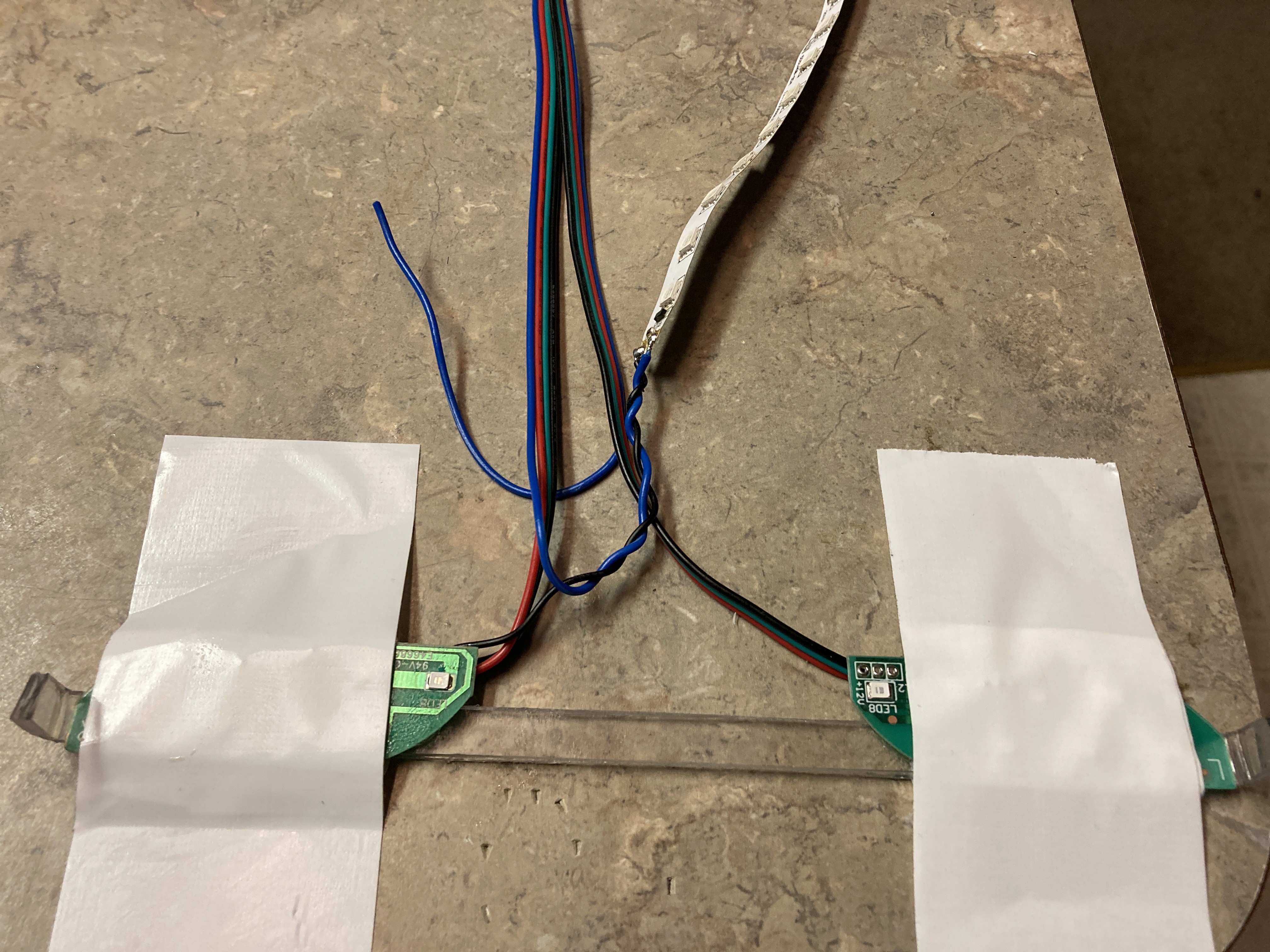

I extended the wiring for the tail-lights, made some kind of mount for them, and add the ground effect LED lights, reflector, and diffusion material.

Preliminary tests prompted me to move the lights higher up into the body to give the lights some more depth for better diffusion. Internal reflection isn't nearly as nice as my mylar light sabre tubes.

I actually have some proper sheets of diffusion material from disassembly of back-lit LCD panels. We will see if they show up before final assembly.

I decided to not add another layer to the top. It was going to be 3 layers at some spots. Now the only place that is happening is the rear lip. This means my top cover can be a single sheet, which means if I have the exact profile for the tire I can do a perfect cutout. This could eliminate the need for a fender.

I have not done final assembly on the tire/hubs/o-ring combo.

I got some iron filings up in the motor somehow. Given I glued the hubs together, I will need to get creative to remove them. This is after wiping the entire thing down with adhesive tape to ensure no stray filings were floating around, and then covering the opening with tape. There must have been some filings inside the tire when I assembled it last. Argh.

I think the pressure washer probably has enough oomph to knock the filings free of the magnets. I will need to be careful to not cut into my hub though with the high pressure, and they will likely just re-attach to the other side until I get lucky enough times.

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.