My second hall sensor is now flaky.

This one I damaged when I swapped the wheel left to right and so had to remove and re-install the wiring. So now I get to pry out my epoxied in hubs. Glad I can still split them first. That would really suck (and was considered).

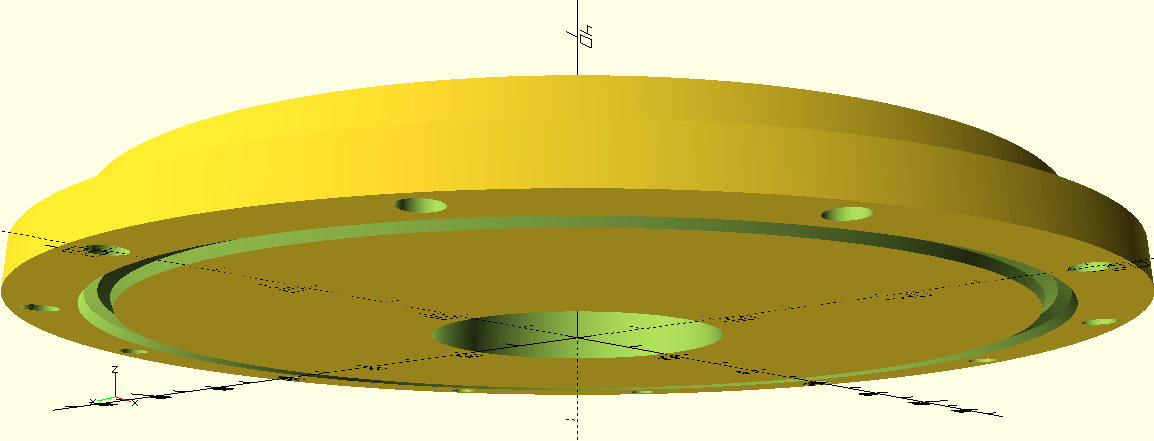

I was also thinking about just printing the bearing plates for the hubs as 15% grid infill, as a solid.

<edit> Like this

</edit>

It may perform better...

Earlier I had mentally tossed around the idea (and never mentioned it) of putting a tablespoon of mineral oil in each hub, hence the previous vaned/open design. Oil pump for my oil cooled hubs.

I think dead space might serve me better as the cooling surface is all at the opposing face anyway, opposite where my hub is. Less oil would do more work and less sloshing around and getting in the way of rotation.

If they start to get hot, they are getting a bath. I can inject the oil after assembly through the shafts, after I seal the wires within the shaft and add some capillary tubing.

Rebuilding/reprinting the hubs. Disassembly later.

<edit>

Build plate not perfectly level. Big, flat part. Part lifted on the back corner.

Re-leveling.

</edit>

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.