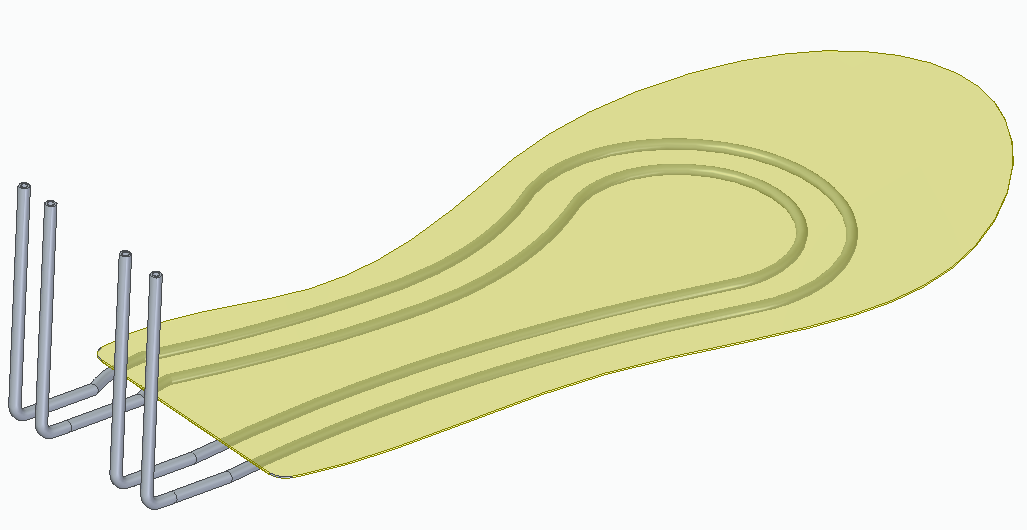

The insole design was simple.

The cooling pipes run through as much as the area of the feet.

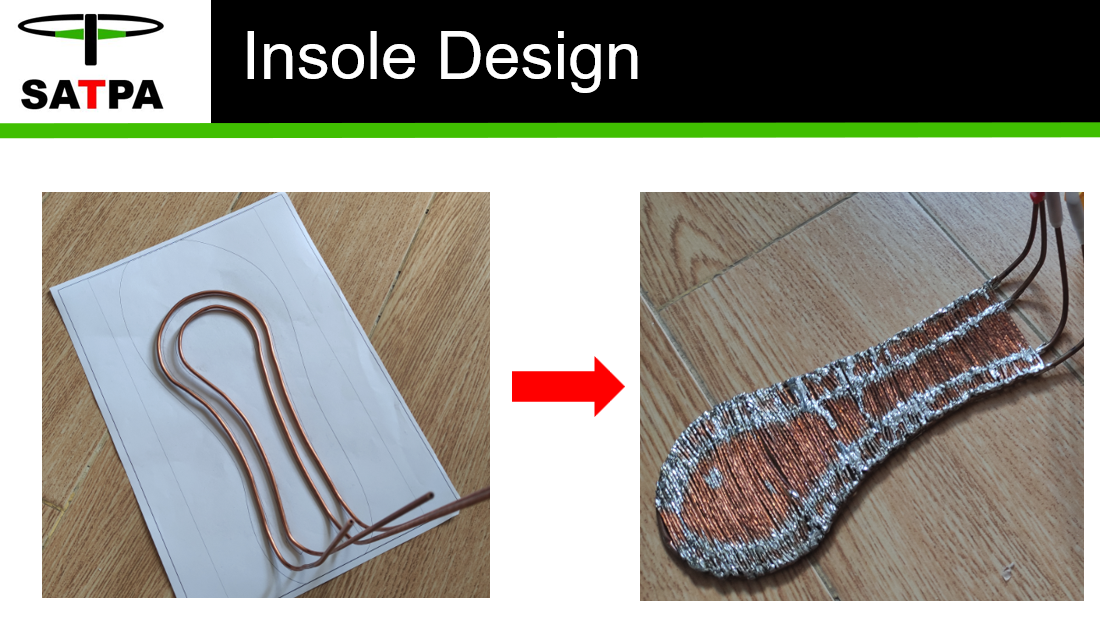

Attach a copper plate to the pipe

However, the cooling area may not be able to extend to the whole feet, and also the flat copper could be designed better to further increase the surface area. Therefore, the copper wires were used instead of the copper plate. As the copper wires were soft, the feet would have better contact with the insole.

The insole was welded and grided. After testing, the wires were able to deform a little bit to adopt the shape of my feet. I am happy with the design, of course, it can be better and that will be improved next time.

Revoxdyna

Revoxdyna

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.