Air quality is something that is usually invisible to us so it is easy to ignore but it does have an impact on us from day to day, “carrying respiratory diseases which affect the probability of you getting infections".

The CO2 level in a closed space is “a good indicator of air quality and can highlight the need for ventilation”. Well-ventilated rooms are crucial for reducing the spread of airborne viruses. Lower CO2 levels are also “linked to improved learning outcomes and better cognitive performance”. In today’s world, this suggests that the way we design, equip & operate our shared spaces is more important than ever.

My project is about exploring the concept of a POP-UP Pavilion - A pavilion that could be installed in different locations to provide space & healthy indoor air quality solutions where needed

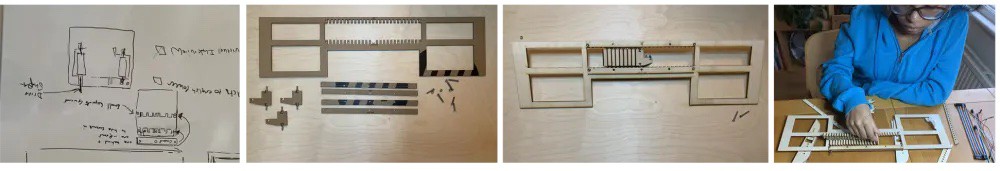

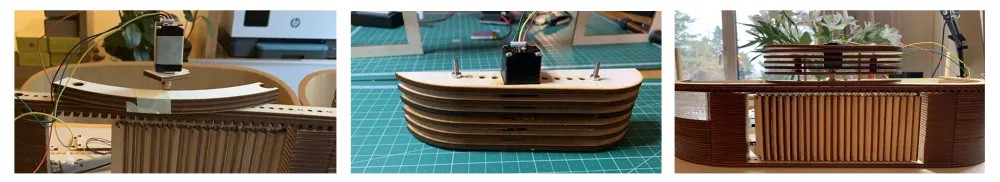

I produced a scaled-down pavilion that uses an internal sensor to monitor & then trigger various reactions to the CO2 levels from inside. The reactions include opening & closing motorized shutter walls, an automatic sliding skylight, a ventilation fan & color-coded CO2 level warning lights.

I have used stepper motors & servos to generate the movement and an Adafruit ESP 32-S2 as the brain stacked with a TFT screen to display the air quality data from the wall of the pavilion. The data is also visualized via IoT on Adafruit IO.

I coded the project using Circuit Python to control the stepper motors, the servos, the Neopixels, the fan, the CO2 sensor, and the TFT screen. I also used CircuitPython to code the visualization of the data on Adafruit IO.

Click on the link below for all details of my Pop-Up Pavilion :

Avye

Avye

Bryan Williams

Bryan Williams

Peter Sinclair

Peter Sinclair

Karsten Fuhst

Karsten Fuhst