The sheet metal cases were designed in onshape and created using the sheet metal tool that exports a nice flat pattern in dxf.

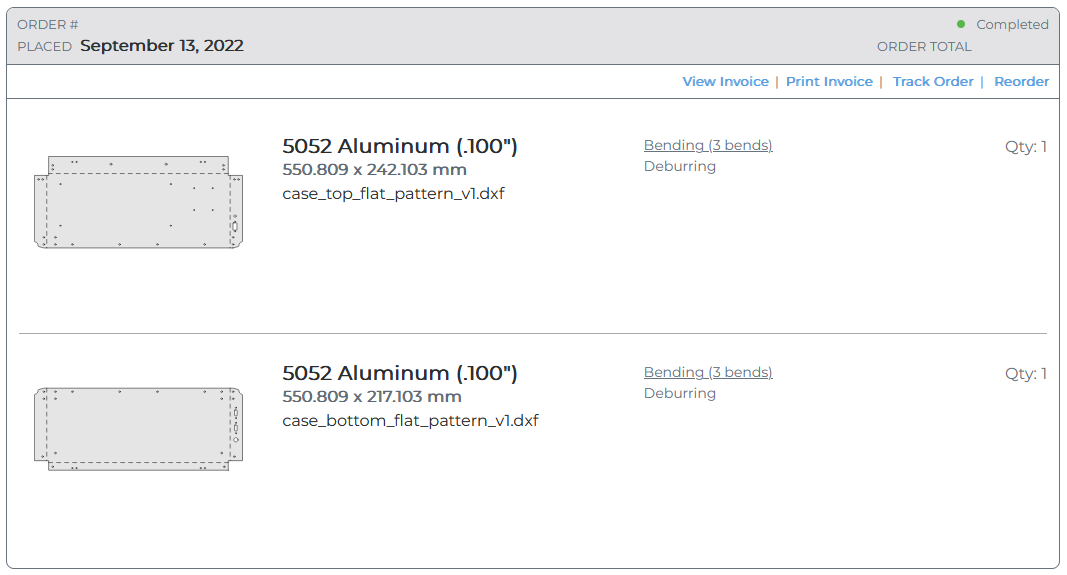

I ordered them through Sendcutsend which also offers bending for an extra price (turns out its per part).

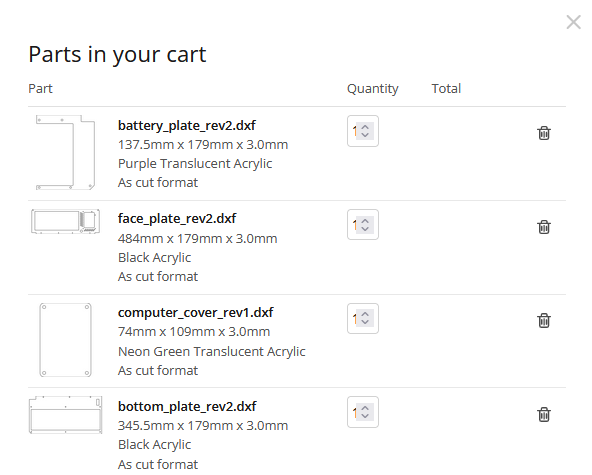

Next I ordered the laser cut parts from Ponoko.

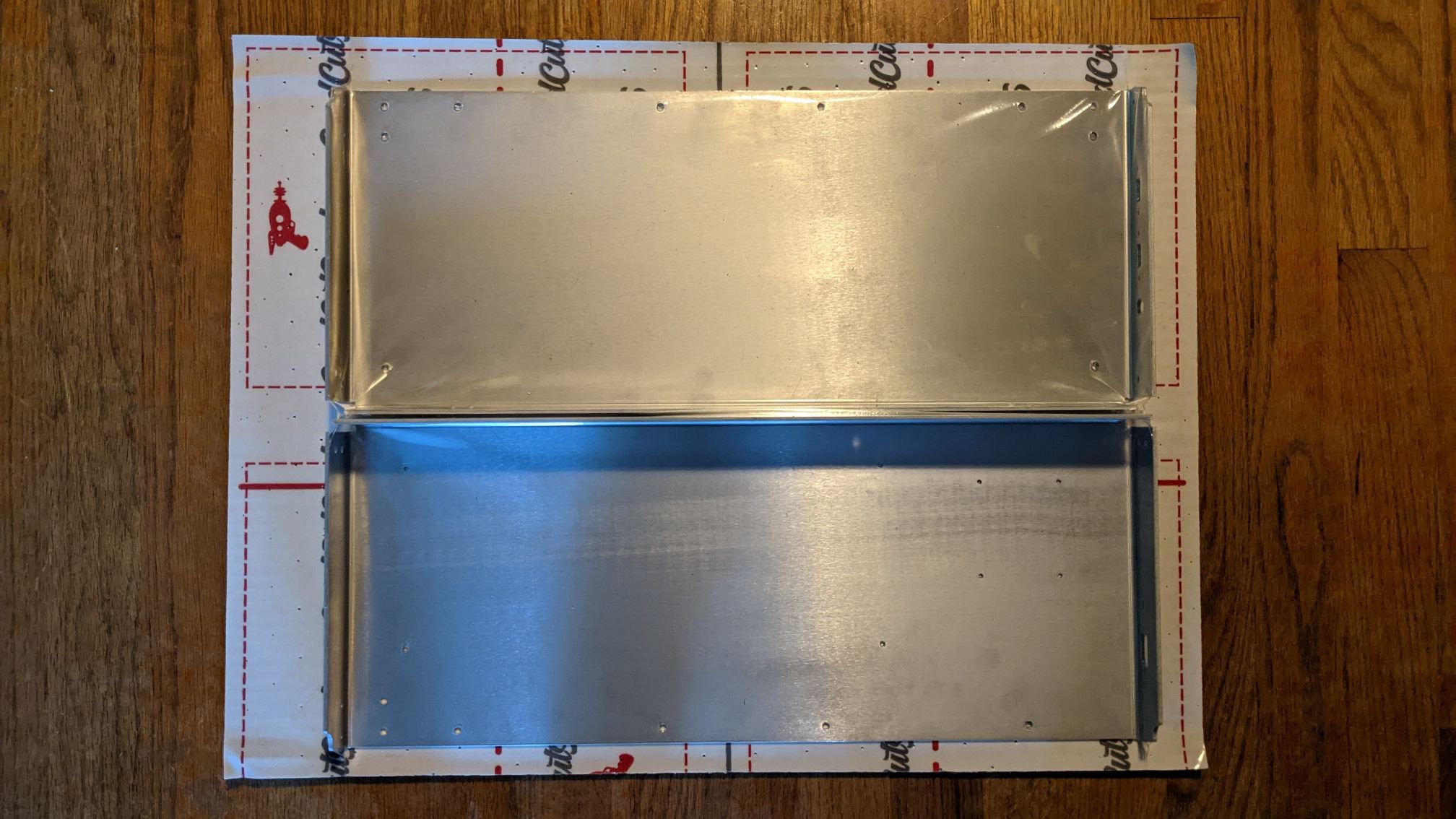

After about a week, they were delivered.

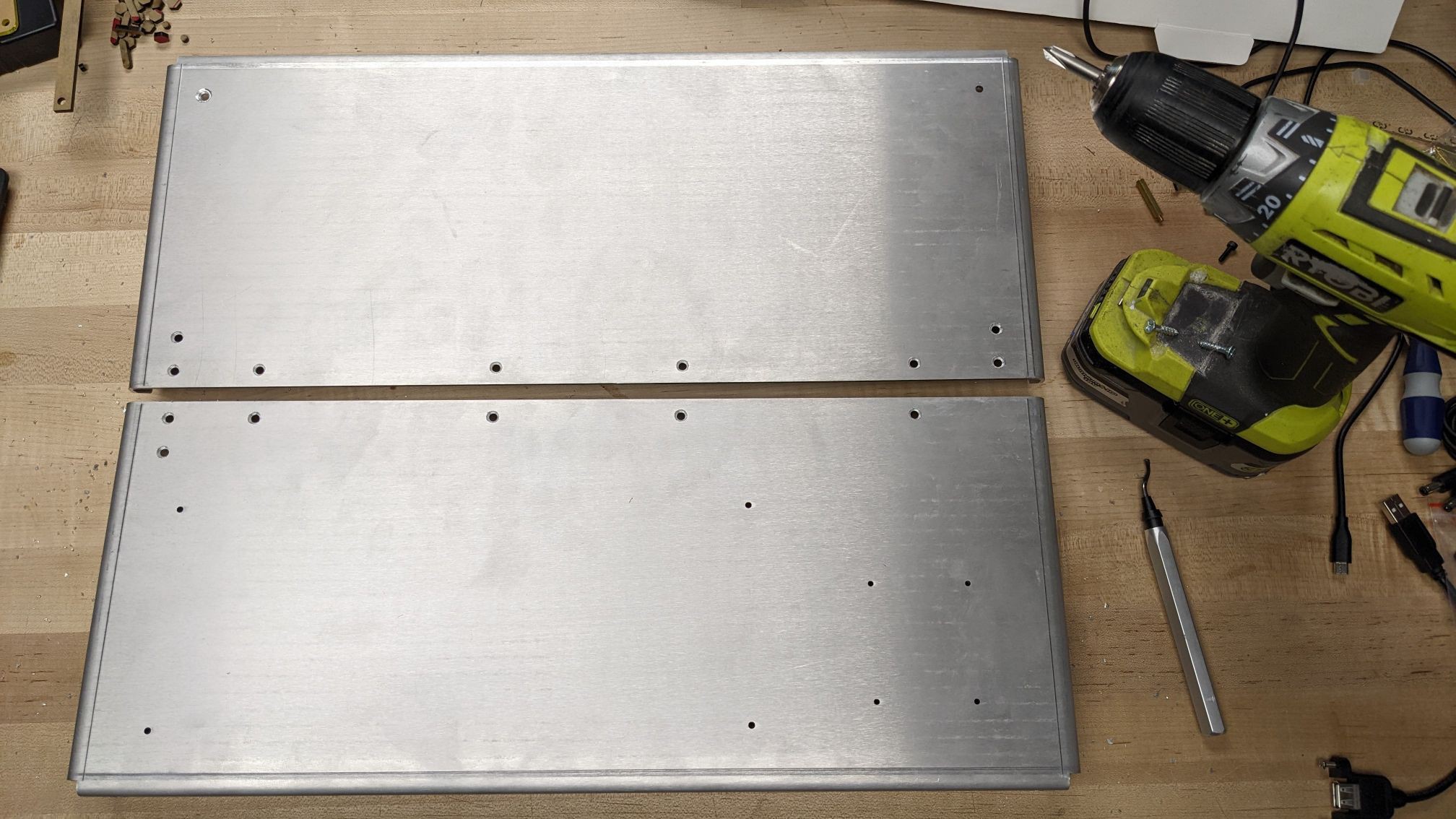

I then drilled all the countersinks for the flathead m4's that are used on 90% of the design.

After countersinks it was test fitting the acrylic from Ponoko.

Next they got painted semi-gloss black (in hindsight, I would paint them matte).

Conceptual Hardware

Conceptual Hardware

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.