The remaining problem to solve was somewhat more dangerous, the machine's casing was live and would often shock the audio engineers, to look for the fault the amplifier was dissasembled and probed while running idle.

This showed the power stage heatsink was live at 100V DC.

It should be noted that this should not necessarily always be a cause for concern since some amplifier heatsinks are live by design, this is because power MOSFETs dissipate their heat better, away from the die and into the heatsink, if theres a direct connection from it's die to it's metalic pad which unfortunately places the die's voltage into the heatsink.

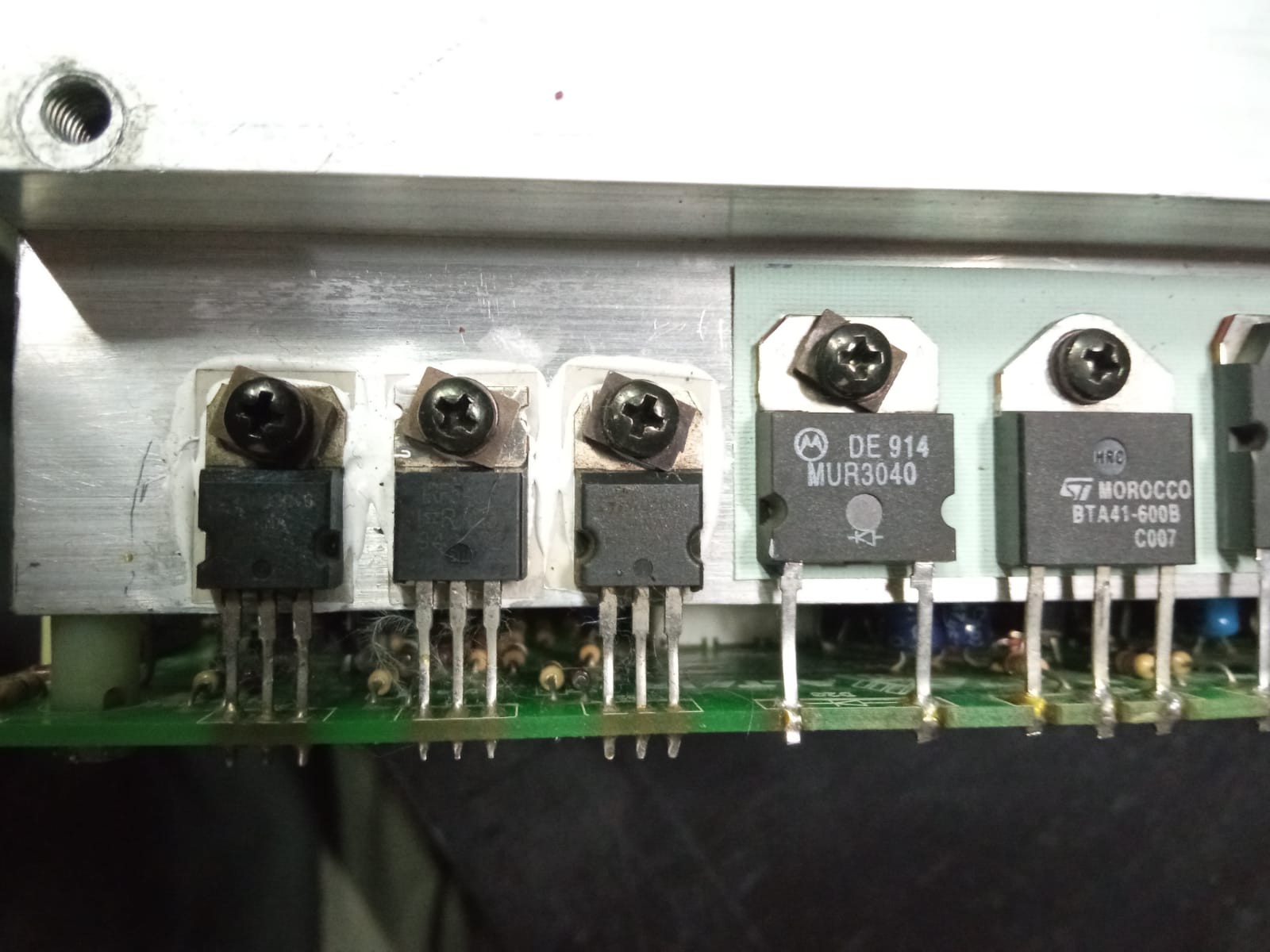

However this could not have been intended since all of the components attached to it had been electricaly isolated with silicone and mica pads. This indicated some isolation had failed and the fault was found probing for shorts (with the machine shut down) with between the components and the heatsink.

The rail tracker transistors (pictured above) were the ones at fault, their mica pads were replaced, new thermal paste was applied and thus the voltage dissapeared from the heatsink and casing.

Finaly the machine was given a cosmetic treatment, the worn out paint was sanded down and repainted, the frontal sticker was sourced and replaced.

guilldeas

guilldeas

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.