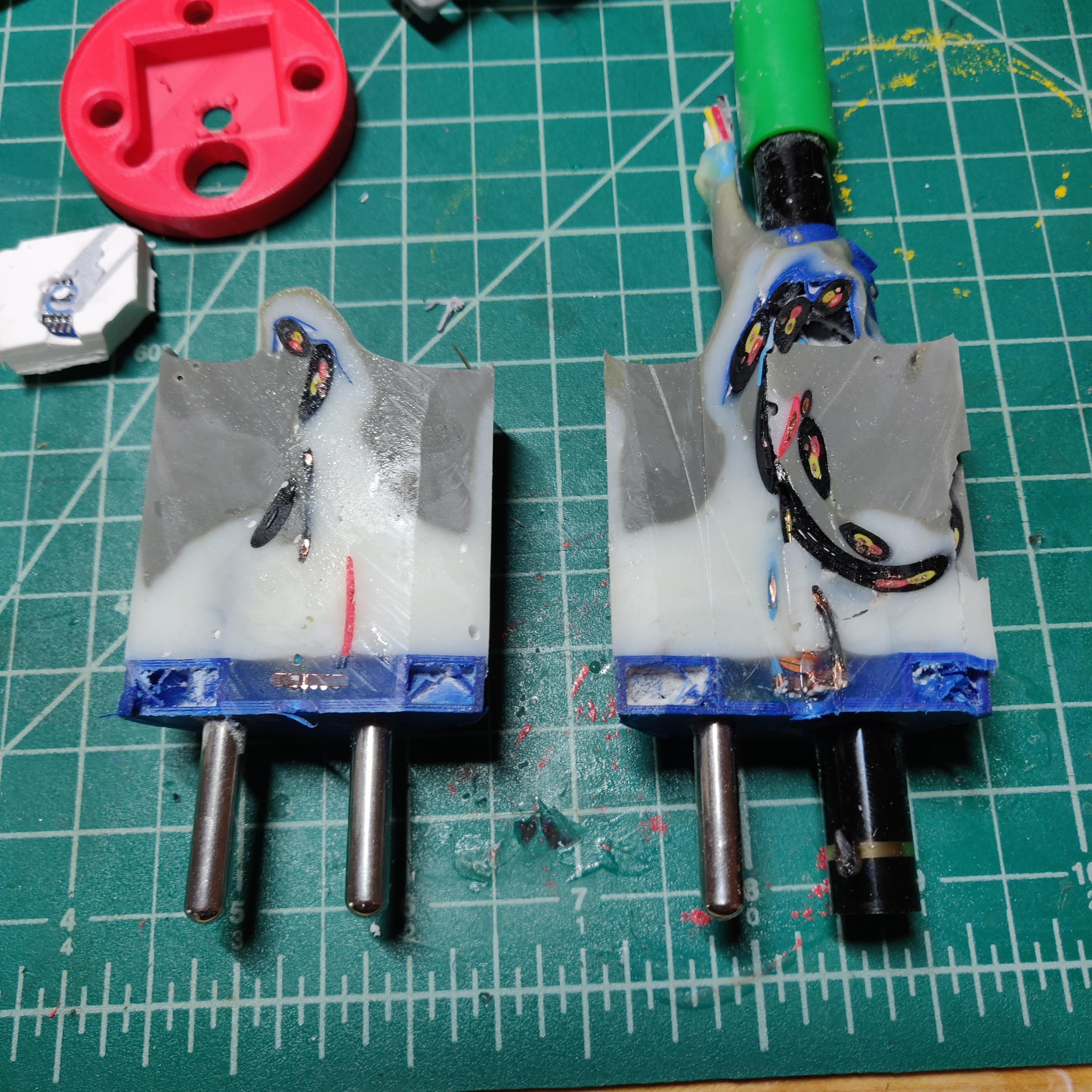

We just finished up a field season deploying OpenCTDs from commercial whale watching boats in New England, giving me a chance to discover all the new and novel ways for these devices to fail. After a summer of CTD casts, this unit finally gave up the ghost and the pressure sensor stopped logging. So I decided to cut it in half and get a look at things on the inside.

First note: this is one of our twice salvaged units from the 2020 field season, where we tested E-40HP (white) as the potting compound and discovered that it really sucked for this application, so there's a whole second layer of E-90FL (gray) in there, too. That was a rush fix and you can see how failed to fill some voids.

We go overkill on epoxy though, so as gnarly as this looks, it didn't leak.

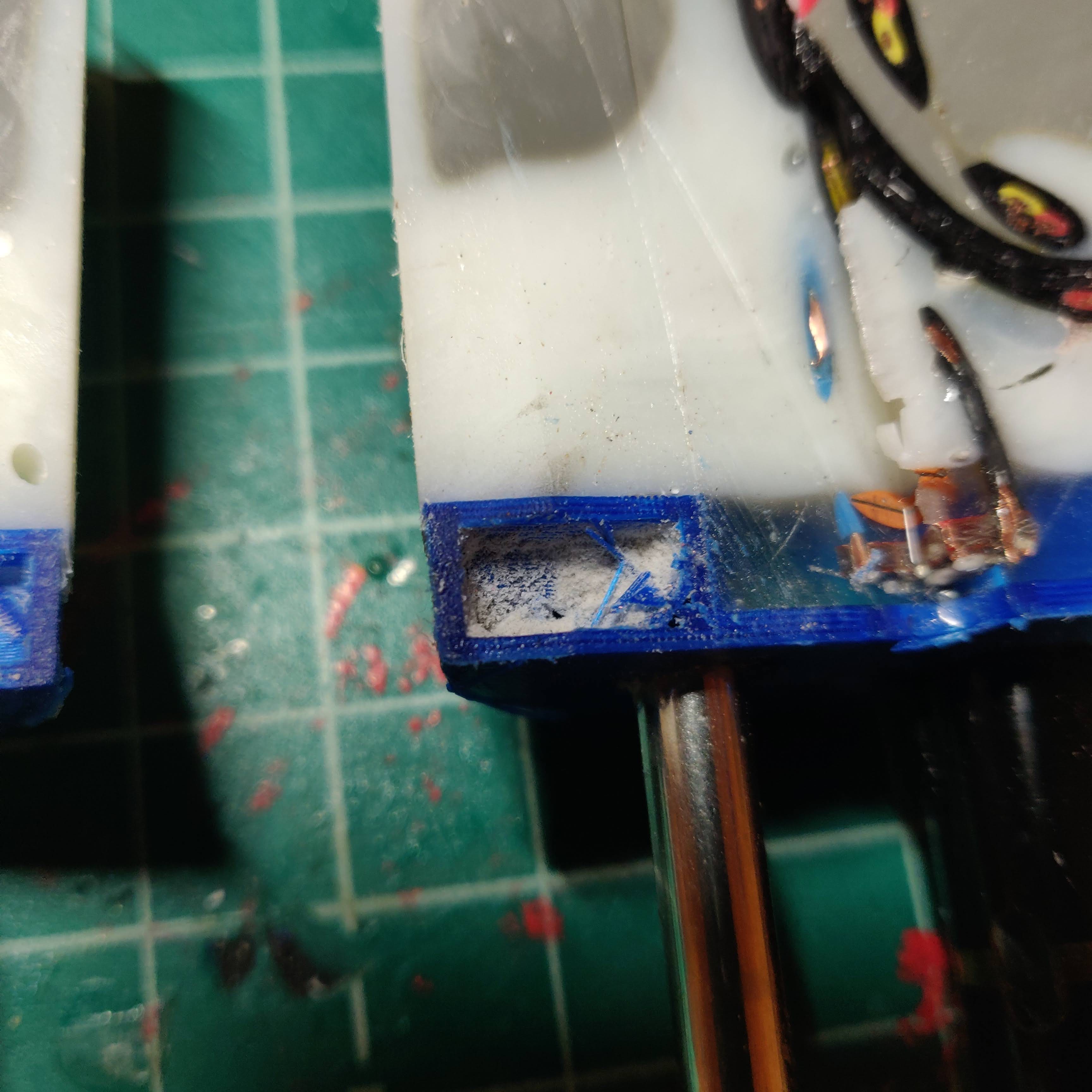

You can see that the infill on the 3d printed baseplate did fill with seawater, and there's tons of salt crystals in there. This isn't a structural component, but it seems sub-optimal, so we'll be printing this part with 100% infill from now on.

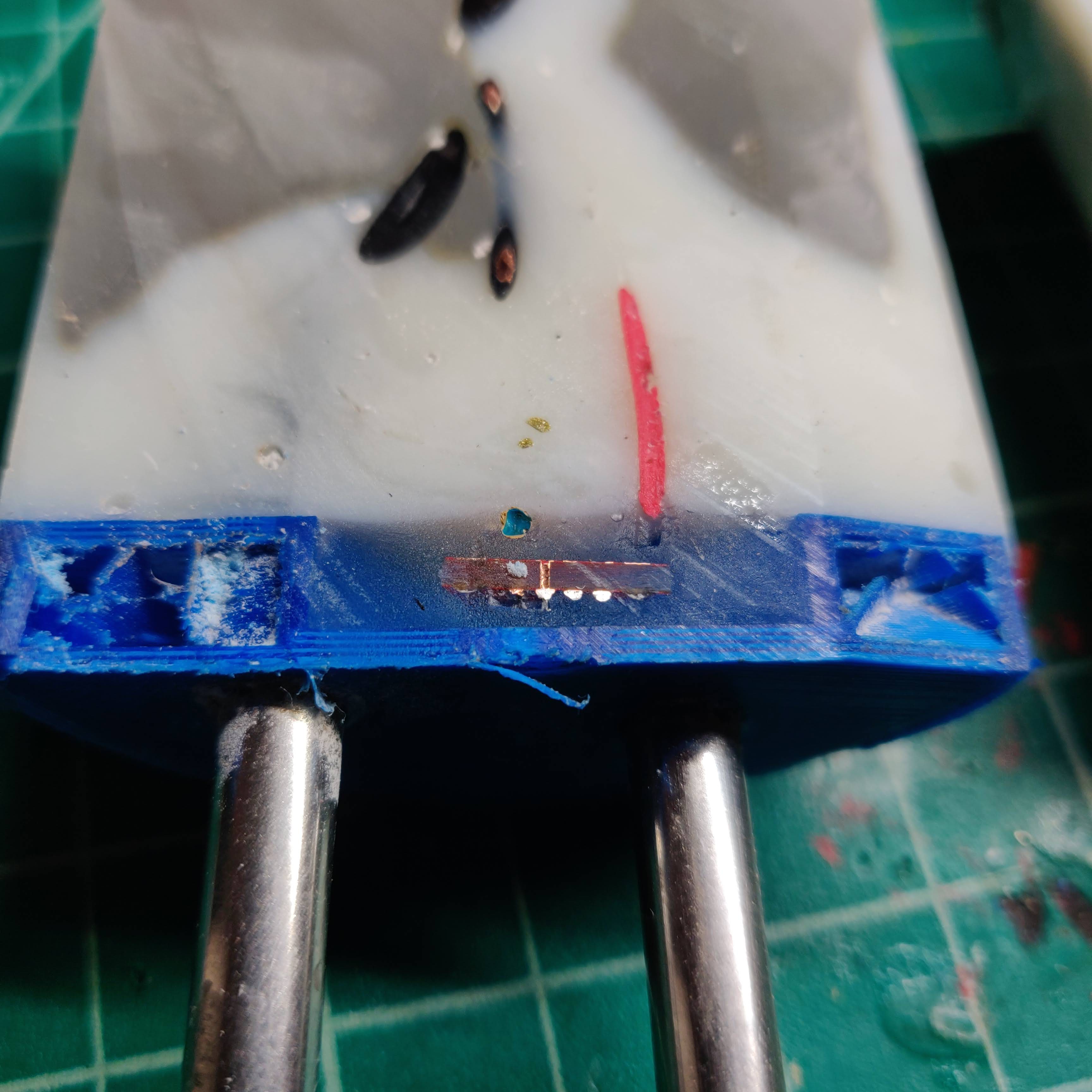

And you can see the other other layer of clear 5-minute epoxy that we use to waterproof the pressure sensor components. it looks like wit didn't completely fill the voids, which is a problem that I believe we've fixed with a redesign of the baseplate that changed how the pressure sensor sits and how the epoxy flows around it.

And yes, we're doing something about that tangle of wires.

andrew.david.thaler

andrew.david.thaler

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.