-

Air passage through sample

10/23/2022 at 02:26 • 0 commentsOne of the questions that has been posed is how is the air traveling through the sample. The assumption in our paper (https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4148065) is that the CO2 is dissolving in the water to become carbonic acid. And this is happening throughout the sample.

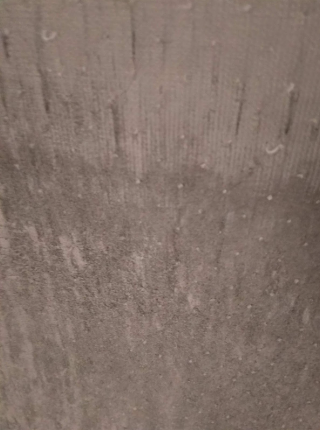

The material is very porous, and here is a video I captured using a clear container to show the micro bubbles which pour from all parts of the sample. -

Closeup of the samples

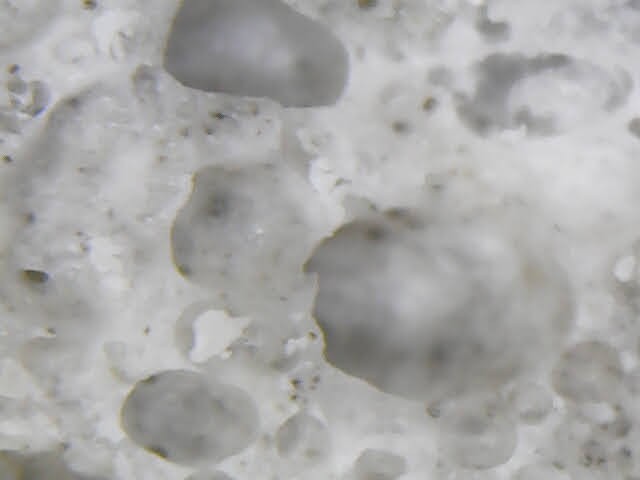

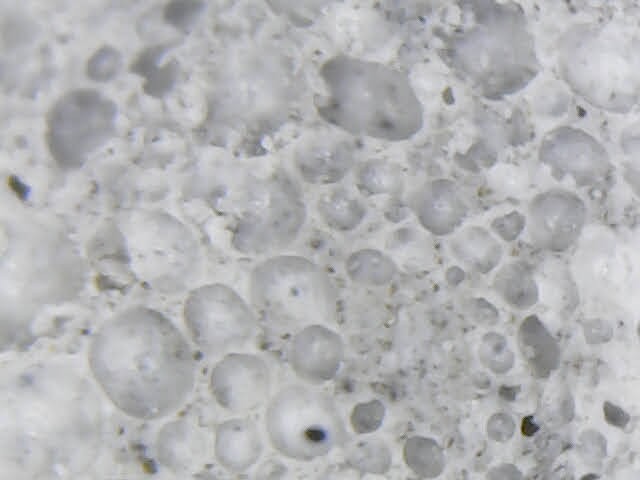

10/23/2022 at 02:21 • 0 comments![]()

![]()

![]()

Control samples

![]()

![]()

![]() Processed samples

Processed samplesHere are closeup images of the samples. The first 3 are the unprocessed samples and the last three are the processed samples. There are notable appearance changes in the material in addition to the weight gain and compressive strength increase.

-

Measuring CO2 Absorption

10/23/2022 at 02:18 • 0 commentsWhen we first started experimenting, we measured CO2 absorption by submerging and then oven drying and weighing the samples. If the sample gained weight, the assumption was it was CO2.

![]()

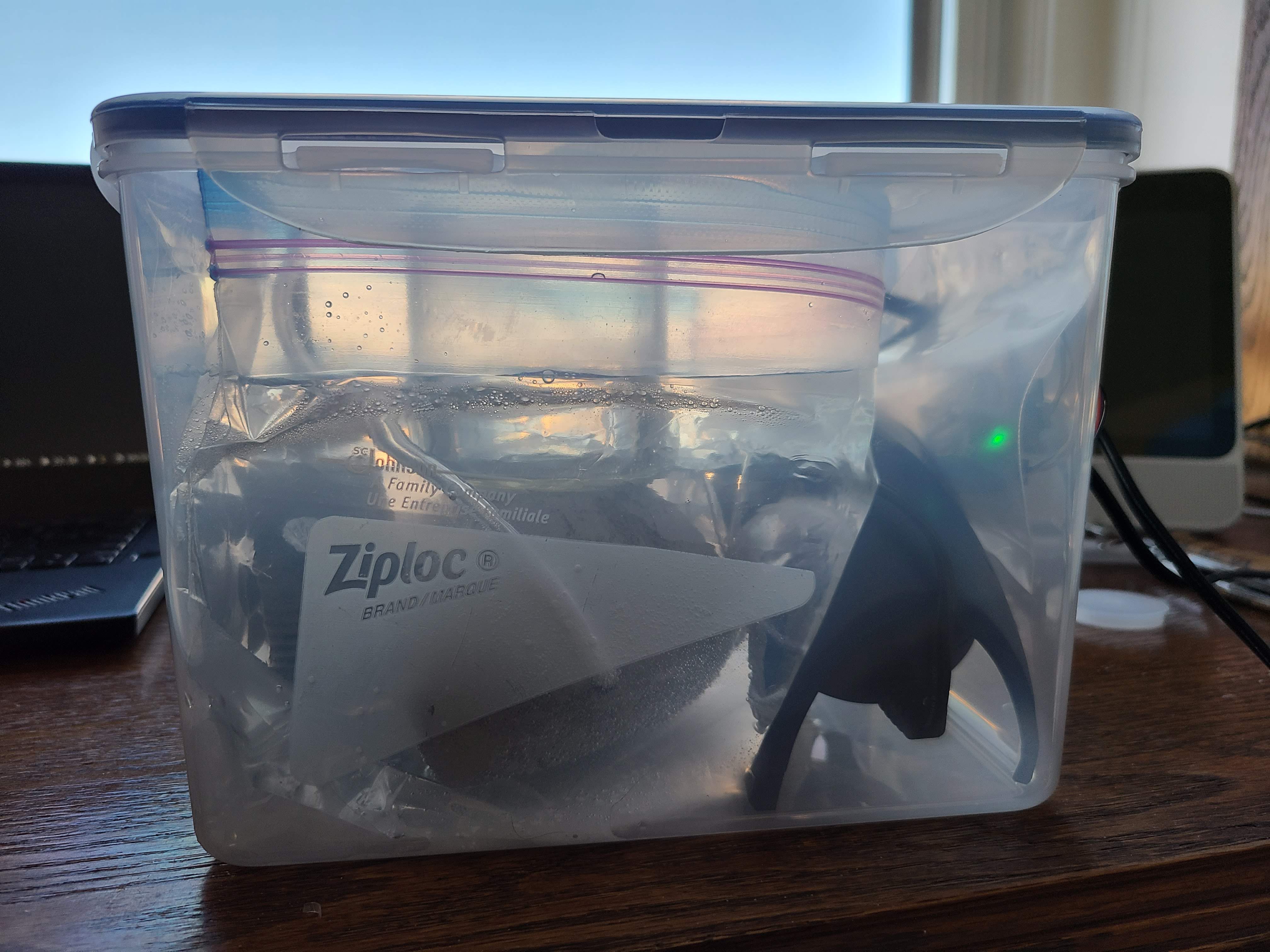

In order to get more data, we purchased a sealed container and put the air pump, sample and solution in the sealed container. We also added a true CO2 sensor https://www.adafruit.com/product/4867 to the sealed container.

We showed in our paper that yes, the CO2 in the sealed container decreased in the air from 800ppm+ to less than 100 ppm. We also repeated with control examples like plain water, water with solution etc.

We are now using thermogravimetric analyzer (TGA) to study the samples and provide further data points as the the absorption of CO2 in the sample -

Small scale testing of sequestration

10/23/2022 at 02:14 • 0 comments![]()

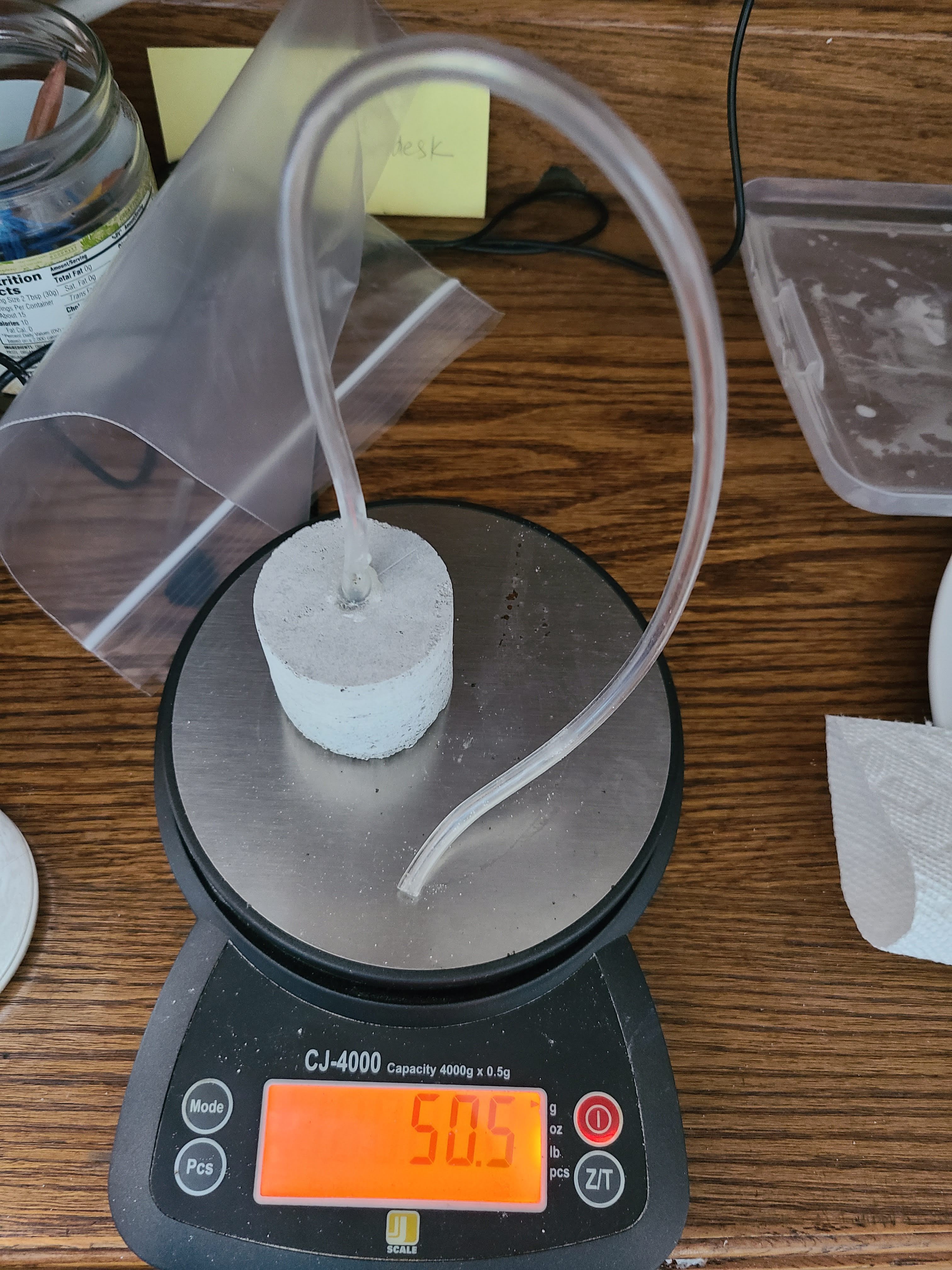

For testing how much CO2 the material is absorbing, we started small with our tests before progressing to the complete buildings. We detail all of this here https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4148065

But first we started with samples of concrete as above. We glued tubes into a hole drilled through the center of the sample.![]()

Then we mounted samples to test stands and connected the aquarium air pump to continuously bubble air through each sample. For each test we added vary amounts of Cation material such as CACL2 to the mix. And submerged the samples for varying amounts of time.

-

We have signed up for XPrize for Carbon Removal

10/23/2022 at 01:47 • 0 commentshttps://pop.xprize.org/teams/10787/overview

We have joined the XPrize https://pop.xprize.org/prizes/xprize_carbon_capture/overview for carbon removal!!

-

testing compressive strength of samples

10/23/2022 at 01:32 • 0 commentsIn our paper, https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4148065 we reference the increase in compressive strength that comes from the sequestration of CO2 in the building.

Any university laboratory and some commercial concrete testing sites will be able to do a compression test. Google "concrete compression test lab"

However, when you are quickly iterating, you will want a cheaper and faster method for getting some initial numbers.![]()

We built a simple test stand out of wood.

We use a 10 Ton bottle jack and a load cell to measure the compressive strength. This is a fast and inexpensive method. You can purchase load cells on Amazon

1. https://www.amazon.com/gp/product/B01HO1GACE/

2. https://www.amazon.com/gp/product/B082MPLRCS/ circuitry to connect to load cell

You will have to calibrate the load cell with a known load cell. -

Outer Wall Finish

10/23/2022 at 01:26 • 0 commentsOne question we often get is what is the finish on the building? This is up to the person building. You can cover with stucco, siding, brick, etc.

We prefer to leave the formwork in place, see picture below, why? It provides a perfect waterproofing and also building envelope sealing.![]()

However, some people have asked if it can be stripped to raw concrete for architectural reasons.

![]()

Yes. This is an example. However, in order to allow for the continuous pumping of air and water for the sequestration, the formwork has to stay in place.

-

SSRN published Sequestration Paper

10/23/2022 at 01:13 • 0 commentsWe have published an early version of our CO2 Sequestration paper here

https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4148065 -

Pumping Concrete

10/23/2022 at 01:11 • 0 commentsFor our larger structures, we have been renting a Putzmeister line pump and pumping concrete from our local readymix company.

However, for AirCrete for this project we wanted to experiment with less expensive to rent pumps. There is no one perfect solution.

1. https://www.westmarine.com/dometic-12v-t-series-waste-discharge-pump-410878.html This diaphragm pump is designed for marine sewage applications. It works quite well and is relatively inexpensive for DIY. However, the Gallons per Minute is too slow for larger buildings.![]()

2. The WackerNeuson diaphragm pumps https://www.wackerneuson.com/us/products/pumps/diaphragm-pumps-of-the-pdi-series are high volume, low cost, and perfect.

![]()

Of course, you will have to washout all of these pumps with water and make sure to clean between each pour. -

AirCrete: What kind of concrete?

10/23/2022 at 01:05 • 0 commentsWhen we started constructing out larger buildings we used a standard readymix company ( https://www.cranesville.com/) in our case and rented a concrete line pump. However, for this project we wanted to use a aerated/cellular/foamcrete ( goes by many names) so that we could experiment with carbon sequestration.

When we started with AirCrete we used these plans https://www.etsy.com/listing/552397572/foam-mate-pdf and simple 7th generation soap. This worked OK and we used it to create small structures like below, these were early prototypes.

![]()

However we switched to the Domegaia system for mixing AirCrete.

Automatic Construction: Inflatable Building

Automatic Construction inflates concrete buildings that sequester CO2. Cheap but durable buildings that save the world

Alex Bell

Alex Bell

Processed samples

Processed samples