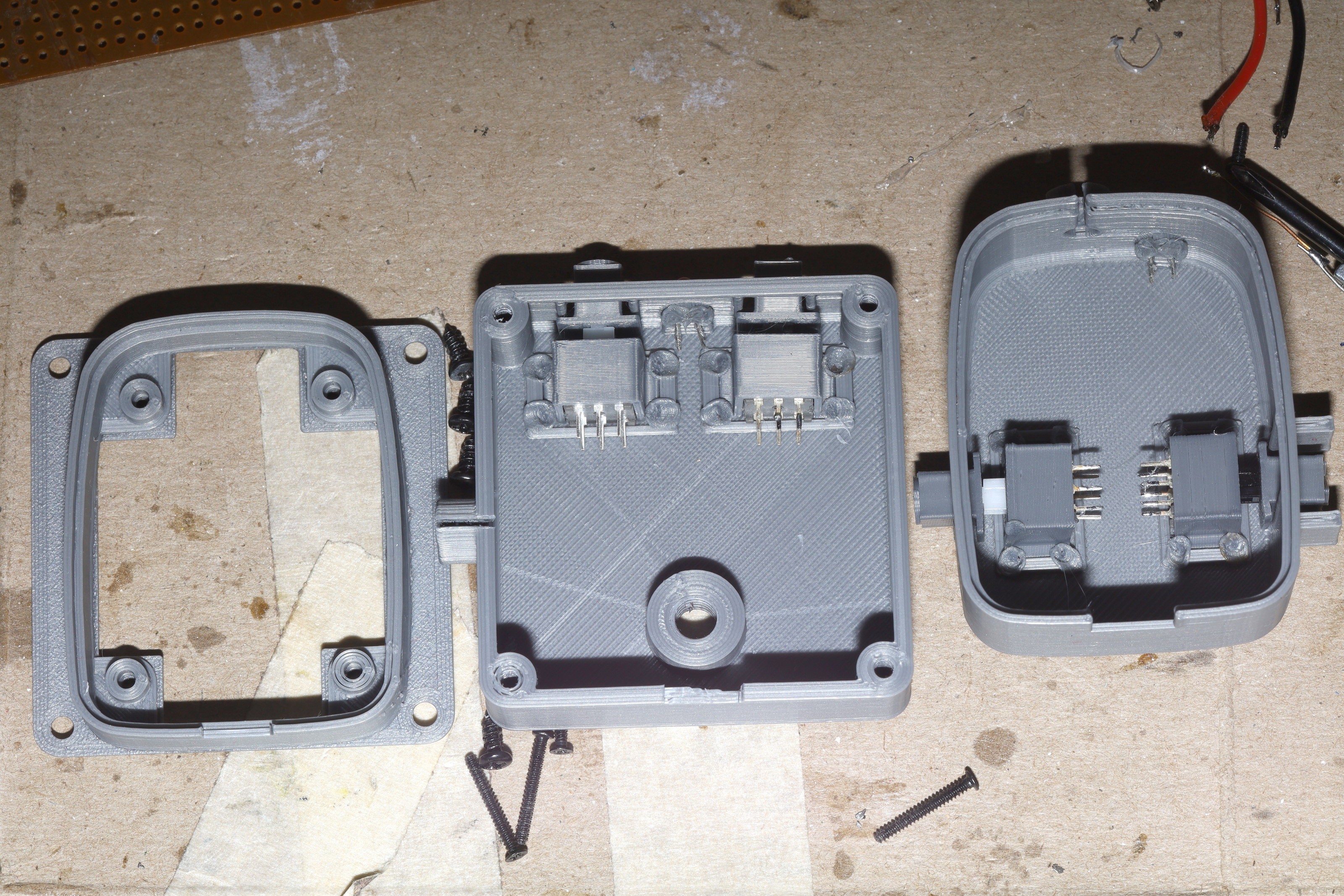

This was the lion kingdom's 1st attempt at using plastic rivets to replace all the hot gluing. Plastic rivets are truly hated in commercial products because they don't allow any servicing without destroying the enclosure, but not so when you can just print a new enclosure. Plastic rivets take a lot less space than hot glue. Many printed designs could use plastic farsteners that melt into position.

The general idea is to have a tall & a short piece side by side. Create an overhang over the short piece by melting the tall piece. It requires a hoof tip at 300C. The trick is to move slowly so a blob of plastic forms in front of the soldering iron & doesn't get pushed to the side. If it's 2 PLA pieces, they can be fused together. If it's a PLA rivet with an electronic part, you have to push the overhang over the part without getting too close to the part.

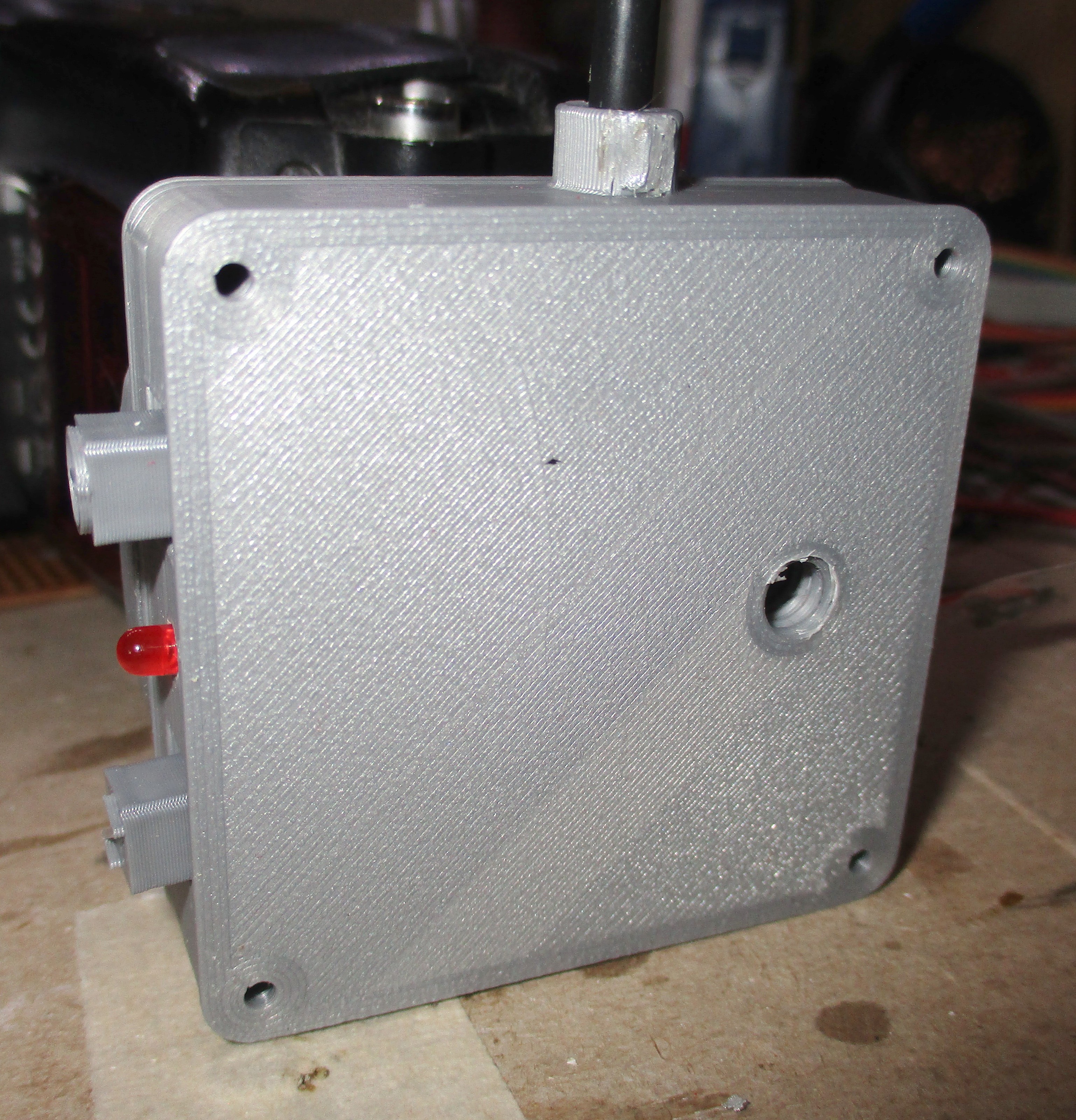

An attempt was made at a PLA tripod head, threaded with a 1/4-20 tap originally bought for rethreading motors. It went through PLA a lot easier than aluminum. This showed promise for at least flashes.

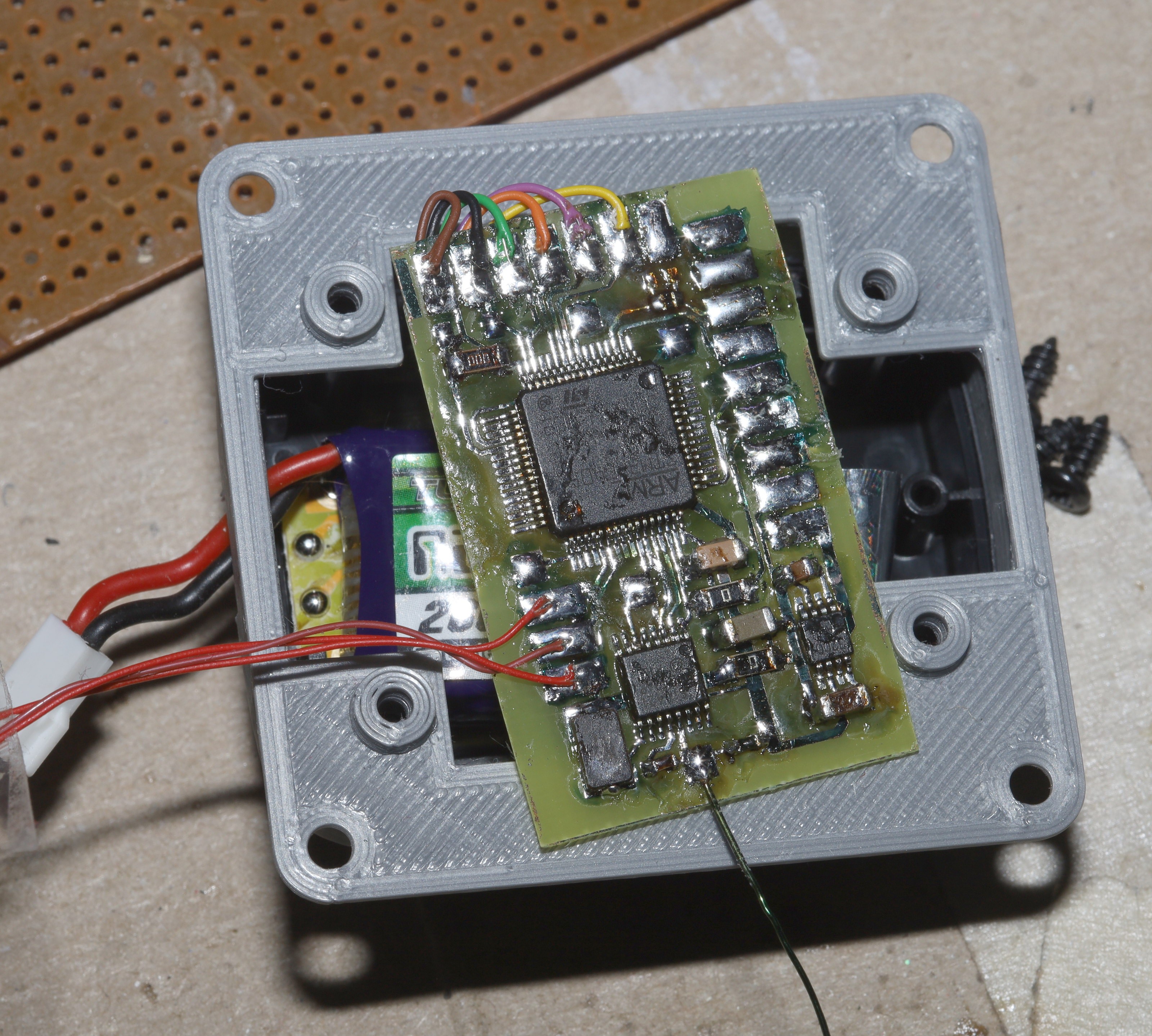

Removing the scotch from the camera side would require a nasty side mounted board carrier. The flash side required a nasty board carrier & side mounting the board to clear the standoffs.

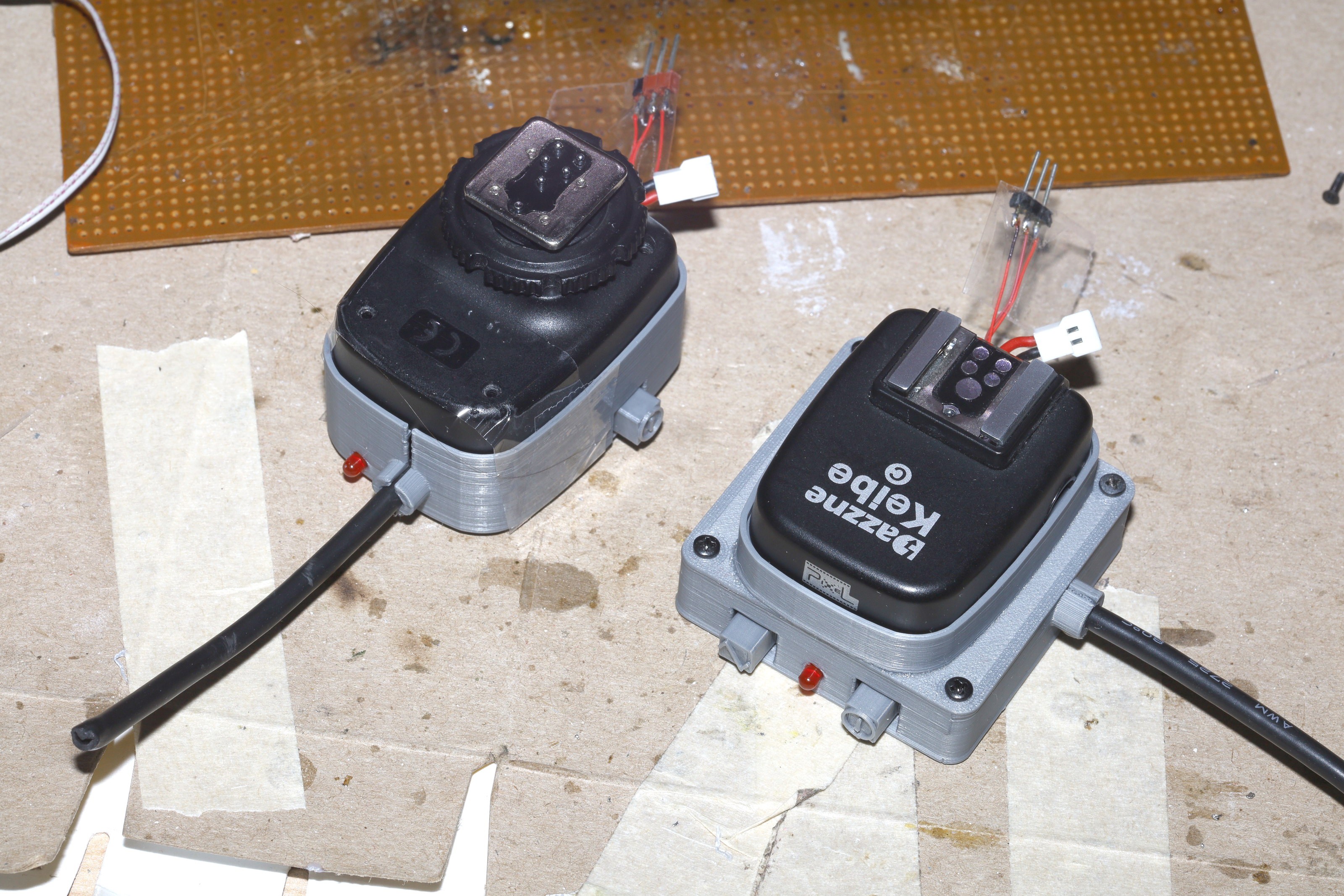

The antennas would ideally both point straight ahead. It's not worth building new boards with repositioned radios. The flash side would have to get 2mm taller to not rotate the board but it would get narrower. The 2 enclosures could have board carriers with forward facing antennas & no scotch. Then, the switch assembly on both enclosures could be straight lined.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.