Using a header as a substitute connector is good, but not mechanically sound.

The header leads are bent at an angle, and the header tends to push up out of the connector well and be loose. It would be useful to have a "clip" of sorts that holds the header against the connector pins.

Fortunately, the connector itself is made to accept a clip-type mating connector.

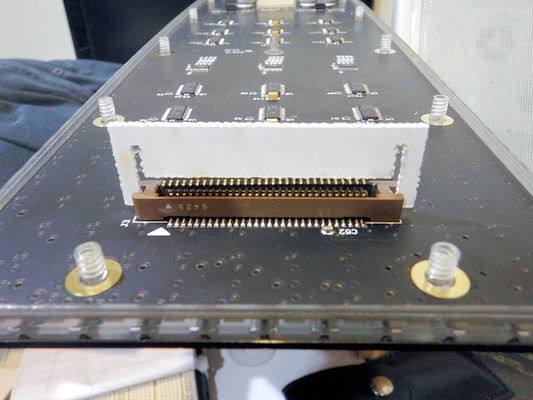

Some initial attempts were made in cardboard to home in on the final design, then an actual clip was cut from thin polystyrene (white, in image below) using a laser cutter.

There's nothing special about polystyrene, it's just what I had on hand. Anything that's thin (thinner than the clip landing on the connector) should do. The landing is roughly 1mm wide, so any laser-cuttable scrap of plastic should work.

I'm guessing that a clip could be 3d-printed, probably the features are too small for FDM but SLS could do it.

The clip works well. It snaps into place, doesn't come out, and gently presses the header pins onto the connector pins.

At this point I could mount the header on a PCB and then firmly mount the PCB into the project (whatever the project turns out to be), but I want to start with Bodge wiring.

I'm not sure yet how the wiring should go, and I need to verify Connor's pinout.

Peter Walsh

Peter Walsh

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.