The piezo-strapped-to-a-heavy-block approach didn't work very well. It was surprisingly quiet, and I struggled to get anything out of my quietest (most expensive) watch. A bit of research, and the general consensus seems to be that adding mass broadens the frequency response at the cost of sensitivity. So, with that in mind, I made a version 2: instead of a heavy aluminium lump, a small piece of 4mm plywood. Stiff enough to give the fragile element some much-needed mechanical support, but light enough not to hammer the sensitivity. Also, a bit 'soggy' to help dampen any resonances.

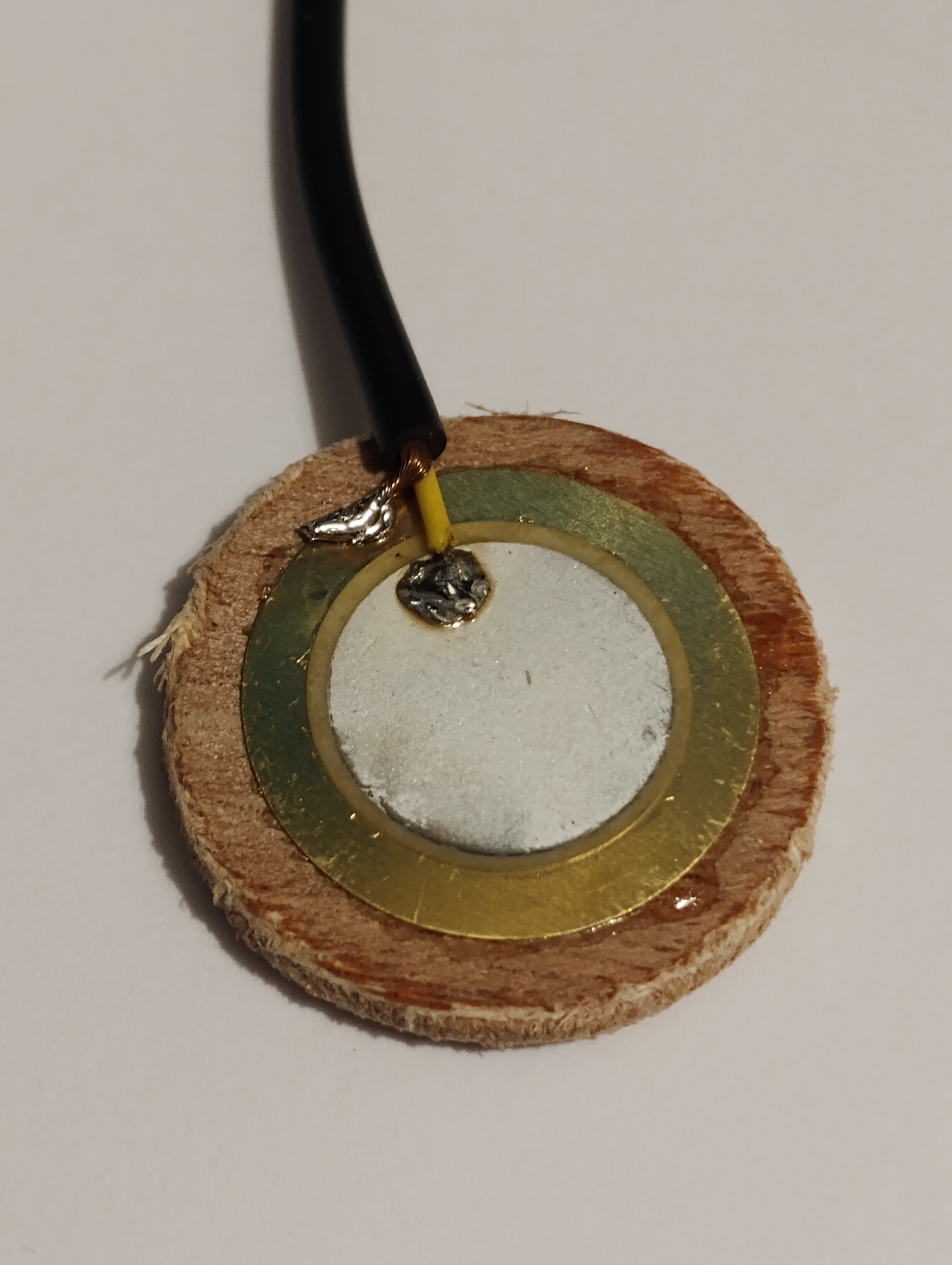

First, superglue the element to a circle of ply. I used a 25mm hole-saw with the centre drill removed. Solder the connections to some screened cable.

Apply some tape (I used Kapton) to cover just the centre electrode - leave the brass base exposed.

Cover with copper tape, then trim back to leave just a little of the brass base showing. Tack solder in a few places to make a good shield against stray interference.

Finally a dot more glue to keep the cable in place and give it some strain relief. There's a new .stl file for the main body of the holder, which has an upright portion that you can glue the mic assembly to.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.