-

Joystick failure 1

11/18/2022 at 18:55 • 0 commentsAnother idea for preventing tangles is interlocking the mane gear with the power switch.

![]()

Testing of the 1st joystick revealed the motor is too hot at the required current. That might be all for the brushed motors. Testing of the joystick could be done with manual means. There are but 2 L6234's left in the apartment.

Tape decks used a clutch to provide constant tension to the takeup reel without stalling a motor.

![]()

The clutch was 2 plastic disks pressed together by a spring. The disks were lined with felt. This provided very little torque. Brushless gimbal motors should be able to replace this.

The right angle required in the joystick creates a lot of friction & fraying of the string, which causes it to jam. The resistance increases as the spool diameter shrinks. It needs a pulley. If it's going to use a pot, the pot needs to have no friction. There's a big deadband where the string isn't pulling sideways enough to move the joystick.

Another idea is having the complete motor spool assembly on the end of a pivot, electronicals & all. That eliminates the right angle, creates a lot more leverage against the deadband. It folds 90 deg for storage. It requires a large pivot. The feed hole could point diagonally.

-

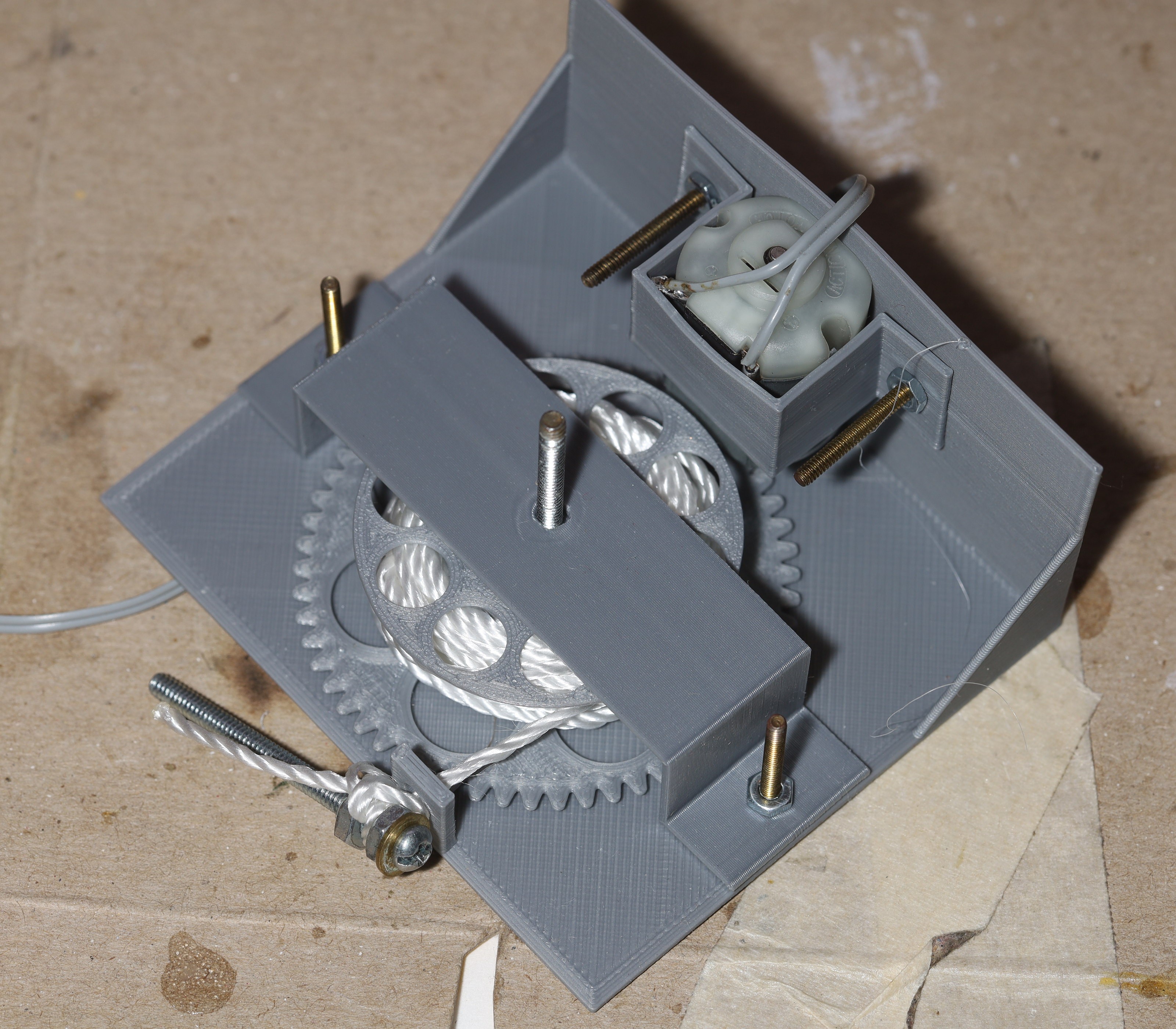

Ridiculous retract mechanism

11/17/2022 at 23:38 • 0 comments![]()

The 1st attempt had a few problems. It was noisy. The motor stalled. The string got stuck on the outside of the torturous path if it moved too fast. A 24mm inner diameter spool was only big enough for 1m of string. The string filled the center of the spool instead of spreading evenly. The torturous path & the motor required a 55mm outer diameter gear. The pinion gear eventually started slipping off the motor as the motor heated & melted the PLA. If the string doesn't retract, the robot won't stop. It has to retract if it's accidentally dropped.

![]()

Spool with torturous path.

Retractable leashes for pet animals have these problems solved, but they're too big to fit in the robot.

![]()

![]()

A conventional spool retracted the full 2 meters quite nicely. 2m is the longest it's going to be extended. This motor is only a proof of concept. A more robust brushless motor would come later. The mane problem is the string does tend to loosen & tangle when it's off. Shorting the motor terminals doesn't provide much braking. If it had a solenoid, it would be pretty complicated.

As the idea evolved, the smart leash could keep the robot behind the animal or beside the animal. The difference is beside the animal, the joystick angle controls speed while the distance measurement controls steering. It would be less accurate & there isn't enough room on the path, but it could be done.

Designs continued for the tangle proof spool & the joystick. The tangle proof spool involved a torturous path for the string. The joystick won't have a spring, but it'll freely follow the string. It'll have a horn constraining horizontal movement but not vertical movement.

An alternative design could have a 2 axis joystick. The higher the vertical position, the slower it moves. This could neglect the string length, but it must handle the case of the animal dropping the string.

Speed based on string length would drop to 0 if the animal dropped the string. Speed based on string height would go to maximum. It would be a dangerous situation. The leading countermeasure is making an exception when the joystick is centered. In that case, stop moving.

It's unclear if the vertical position could be sensed accurately enough. The string isn't going to stay taught without the string retractor, so any kind of joystick needs the string retractor.

-

Autonomous navigation plan

11/17/2022 at 23:23 • 0 commentsA line projector has been long dreamed of for steering a robot from in front.

Autonomous navigation when walking for short distances has been highly prized for eating. It's just been the real simple problem that tortures by a thousand cuts.

The cowarobot is the most popular robot suitcase. It is not trivial. It has 4 cameras in the handle for bearing & distance. It doesn't work in direct sunlight. They don't use a bracelet for tracking. The bracelet is for notifying when it has lost contact.

The airwheel SR5 uses a bracelet for UWB tracking. The UWB tracking is notably less accurate than machine vision but works in sunlight. The DW1000 is the most famous UWB chip. There is an arduino library for the DW1000 but it only computes distance from signal strength, not time of flight. The general idea is the higher the bandwidth, the more precisely you can measure the time of flight of a packet. Time of flight becomes possible in the 6Ghz range.

For all the vijeos teaching how to program neural networks & win programming contests, it's amazing how little anyone knows about how a robotic suitcase works.

There was once an idea for a leash, for either pulling it up hills or when the battery died. The problem was the size leash it would take to transfer enough force to pull it from far enough away.

If the application is just autonomous navigation when walking for short distances, there could be a smart leash. It would measure axial tension to control speed & steer by detecting sideways tension. It could be very light. The trick is designing a small enough sensor which detects sideways & axial tension.

There are very large strain gauges for 1kg loads.

https://www.adafruit.com/product/4540

There are slightly smaller flex sensors for smaller loads.

https://www.adafruit.com/product/1070

The bare chip sensors found in bathroom scales are unobtanium.

Because of the size of strain gauges, there is more value in connecting the string to a hall effect joystick for steering. Measuring axial tension is a difficult problem. The problem is the animal is not going to manetain a constant distance from the truck. The ideal leash needs to be 2-4 meters with distances from 2-4 meters determining speed.

The leading idea is routing the string through the joystick to the tension sensor. The leading tension sensor is a measuring tape spring with encoder. It adjusts throttle depending on how much string has come out. A UWB sensor could measure the length of string, but it would be redundant when the need to tension the string is factored in.

A spring loaded cable reel with encoder is the simplest idea but commercial ones over 1 meter are gigantic. Farstening a 1m retractable segment to a fixed length string segment & passing it through the joystick would be difficult.

Because of the low usage & low power, a brushed motor could tension the string, but it also has to be fast. A sensored brushless motor would provide tension & encoding but require a motor driver & heat sink. The l6234 is no longer made.

It might be easier to have the user hold a retractable string & the truck to just have the joystick, but it would entail a transmitter worn by the user. There's still a user worn retractable string with a load cell on the joystick.

For testing, a toothbrush motor can create tension with 2V at 1.5A. A large diameter brushless motor would be a long term solution. The problem is the string isn't always under tension, so it's going to want to tangle.

lion mclionhead

lion mclionhead