My friend Emma at Cut Clover Flowers sent me an email a couple months ago titled "Not a vacuum tube but could be fun anyway?" She operates an independent flower farm about a half hour drive from her home. The farm has a greenhouse with sides (aka curtains) that roll up and down with a crank to maintain the temperature inside. She wanted a way to maneuver them automatically when the greenhouse temperature reached certain levels.

There are systems to do this available on the market. They replace the hand cranks with roll motors, which are operated by control boxes with built-in thermostats. These systems can cost over $4K. Emma wanted to know if I could do it cheaper.

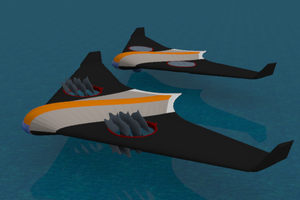

Each roll motor attaches to a trolley that travels along a guide pipe positioned vertically next to the greenhouse, one for each side. The motor turns a long metal pole that travels the length of the greenhouse, around which the curtain is wrapped. The motion of wrapping or unwrapping the curtain moves the motor up or down along its guide pipe. For more insight, check out the images and video on this page.

Emma pointed me to the following videos which feature much less expensive DIY systems. They operate on 120VAC line power. There was no power available at Emma's greenhouse, so she needed a solar powered system.

- Automatic greenhouse side curtains - Farmer Keith

- Automatic greenhouse side curtain wiring - Farmer Keith

- Greenhouse roll-up sides DIY - The Hodge 101

I selected the Advancing Alternatives LVM60 curtain motors. Cheaper motors are available but Emma wanted to go with a trusted brand. I calculated the number of watt * hours required, assuming the curtains would need to travel up and down once per day. I used this online calculator to find how many solar panel watts and battery amp hours we would need.

Armed with this information, I selected batteries, a solar panel, and a charge controller. The motors require 24VDC, so I chose everything to match this voltage. I realized late in the game that the greenhouse had two curtains instead of one, so I ended up buying four 12V, 12AH batteries when two 12V, 20AH batteries would have sufficed. The charge controller was not a trusted brand, but it drew the least amount of current (10 mA) of any I could find.

For controlling the motors, I used the same thermostat used by Farmer Keith in the videos above, taking care to wire it as he suggested (switching the load, not the source). Industrial thermostats like this one are mechanical and require no power (so cool!). This one has a unique double pole, double throw (DPDT) relay that makes it ideal for reversing the polarity to the motors, causing them to move in the opposite direction. I was worried because this thermostat is rated to switch AC current, not the DC current needed by the motors. DC currents are more capable of damaging switches than AC, especially when using inductive loads like motors.

I decided this was not a problem however, because the thermostat would only be used to turn on the motors, never to turn them off. The motors have built-in, adjustable limit switches that stop them when they have rotated to a certain position in each direction. There are diodes in parallel with each limit switch that allow the motors to move in the opposite direction if the current is reversed after the switch has been tripped. The motors would be turned on by the thermostat and then stopped by the limit switches when the curtains made it all the way up or down. Therefore the limit switches would be solely responsible for opening the circuit, and the thermostat would only be used to close it. The danger when switching inductive loads comes from the collapsing electromagnetic field when a switch opens while current is flowing. The field can create an arc between the switch contacts which can damage them. The risk is minimal when a switch applies power to an inductive load because the field has not been created...

Read more » Justin Scott

Justin Scott

ken.do

ken.do

Jarrod

Jarrod

Hi, Emma shared this with the MD cut flower group and I’m trying to replicate it on my 96’ tunnel. Any tips/updates? I want mine to remain open until it hits 40F. I worry about fluctuating winter temps making it go up and down a lot.

Let me know if you feel like driving up into MD to install another! I am in a sticky situation this winter and need to have this operational. Thanks for any advice!