i vent ours outside , since it has a lot of contaminants in it

i vent ours outside , since it has a lot of contaminants in it

![]() Probably with some filler in the rubber.

Probably with some filler in the rubber.

co2, fibre, all of them outside you can do it into an active carbon filter as well to help, but its a lot of gas and very small particulate

co2, fibre, all of them outside you can do it into an active carbon filter as well to help, but its a lot of gas and very small particulate

![]() would bubbling through water do the job instead of a filter?

would bubbling through water do the job instead of a filter?

World's worst hookah

World's worst hookah

it'd need a lot of flow, but maybe, waterjets do use the water to help with that too, so its feasible, but there is still the gas depending on what you're cutting

it'd need a lot of flow, but maybe, waterjets do use the water to help with that too, so its feasible, but there is still the gas depending on what you're cutting

Hey @Jonathan Schwartz - we're past an hour now. Want to keep going or wrap it up?

Hey @Jonathan Schwartz - we're past an hour now. Want to keep going or wrap it up?

![]() Aliexpress has some sweet-looking "80 watt" 450nm lasers. How much should I trust the offer? (Assuming incoming power instead of optical.)

Aliexpress has some sweet-looking "80 watt" 450nm lasers. How much should I trust the offer? (Assuming incoming power instead of optical.)

![]() they are reportedly combining power from two diodes.

they are reportedly combining power from two diodes.

![]() it may have multiple chips and beam combining in-module.

it may have multiple chips and beam combining in-module.

![]() I had good experiences with thin white material cutting when the line was dyed yellow.

I had good experiences with thin white material cutting when the line was dyed yellow.

![]() Thank you!

Thank you!

makes a lot more sense when you're watching the youtube too heh

makes a lot more sense when you're watching the youtube too heh

![]() another trick, engraving polyolefins. paint the engraving areas (text) with a black pen, then scan with defocused blue laser.

another trick, engraving polyolefins. paint the engraving areas (text) with a black pen, then scan with defocused blue laser.

![]() translucent material ignores the beam, paint heats and bakes into surface.

translucent material ignores the beam, paint heats and bakes into surface.

![]() TRICKS! Do tell do tell do tell!!!

TRICKS! Do tell do tell do tell!!!

![]() the trick was to make sure text on polypropylene bottles of solvents won't wash off.

the trick was to make sure text on polypropylene bottles of solvents won't wash off.

![]() Any interesting fails? My one was trying to use nascent iodine generated from laser decomposition of iodoform, to etch copper on circuitboards. The copper totally ignored the process and everything stank like an old hospital for DAYS.

Any interesting fails? My one was trying to use nascent iodine generated from laser decomposition of iodoform, to etch copper on circuitboards. The copper totally ignored the process and everything stank like an old hospital for DAYS.

colour is interesting, we managed once to make repeatable colour with our mopa but never again.

colour is interesting, we managed once to make repeatable colour with our mopa but never again.

![]() logical. focal point on surface vs in the middle of the material thickness.

logical. focal point on surface vs in the middle of the material thickness.

its very sensitive to temperature

its very sensitive to temperature

![]() thought. selective surface melting. coat a surface with a powder, eg. plastic or solder, and then raster/trace over.

thought. selective surface melting. coat a surface with a powder, eg. plastic or solder, and then raster/trace over.

which is a big issue with fibres and metal, the work area heats up and changes the cut properties. so much easier with co2 wood/plastic

which is a big issue with fibres and metal, the work area heats up and changes the cut properties. so much easier with co2 wood/plastic

![]() then brush off the unmelted powder.

then brush off the unmelted powder.

![]() you can also engrave atypical stuff. I had success with sugar candy.

you can also engrave atypical stuff. I had success with sugar candy.

i like making keychains :)

i like making keychains :)

![]() what about a 5-axis head for the laser? engraving non-flat objects?

what about a 5-axis head for the laser? engraving non-flat objects?

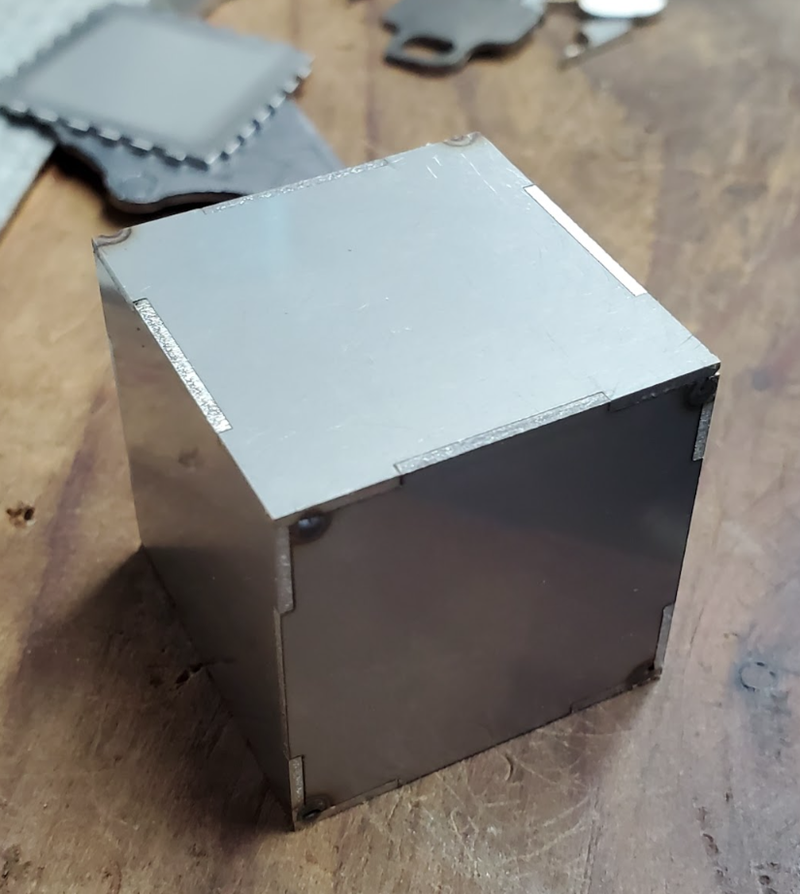

carbon steel

carbon steel

yes

yes

3/16th

3/16th

in the garage

in the garage

LA

LA

sure , i'm in northridge

sure , i'm in northridge

![]() that's a SWEET machine!

that's a SWEET machine!

![]()

https://www.improwis.com/projects/food_LaserEngravedCandy/

Laser engraved candy

Because, why not? Does everything need a justification? This was the inspiration: Bittersweets, the despair.com Valentine candies A 40W CO2 K40-III laser cutter was employed. A test image ("test" text) was used for the engraving. The candy used are the kind consisting of pressed sugar, with some added starch, citric acid, flavorings and dyes.

1kW fibre

1kW fibre

![]() could it be done via 3d-scanning the object, then autogenerating the paths of the 5-axis thing to deliver beam perpendicularly to the object where desired?

could it be done via 3d-scanning the object, then autogenerating the paths of the 5-axis thing to deliver beam perpendicularly to the object where desired?

sure, we are usually hanging out saturdays and doing stuff

sure, we are usually hanging out saturdays and doing stuff

![]() g-code is the easy part. gcode is nothing but positions of the machine. a bit of math. brain-melting math at times but still just math.

g-code is the easy part. gcode is nothing but positions of the machine. a bit of math. brain-melting math at times but still just math.

you can laser weld too

you can laser weld too

![]() 3d gcode (and multiaxis) can get crazy. i never got beyond 2.5d yet, and failed to understand CAM software correctly so mostly just generating the toolpaths in python.

3d gcode (and multiaxis) can get crazy. i never got beyond 2.5d yet, and failed to understand CAM software correctly so mostly just generating the toolpaths in python.

do you mean the 3d capture obama project?

do you mean the 3d capture obama project?

ahh ok, i meant this one https://www.bbc.com/news/av/world-us-canada-30306967

ahh ok, i meant this one https://www.bbc.com/news/av/world-us-canada-30306967

![]() femtosecond lasers are fun too. any knowledge of them?

femtosecond lasers are fun too. any knowledge of them?

![]() or the copper-vapor ones?

or the copper-vapor ones?

would love to get a femtosecond

would love to get a femtosecond

![]() short pulsed lasers can vaporize material before the underlying layers can even notice something is happening.

short pulsed lasers can vaporize material before the underlying layers can even notice something is happening.

@Jonathan Schwartz - thanks so much for your time today, this was really helpful. And thanks to everyone for the great questions!

@Jonathan Schwartz - thanks so much for your time today, this was really helpful. And thanks to everyone for the great questions!

FYI, I'll post a transcript in a few minutes, along with a link to the YT video. Thanks all!

thanks a lot!

thanks a lot!

Jonathan, I joined late but the info you shared was very useful, I will be rewatching this one.

Jonathan, I joined late but the info you shared was very useful, I will be rewatching this one.

![]() also you can cut biomaterials. lasers are used in medicine.

also you can cut biomaterials. lasers are used in medicine.

![]() co2 as a scalpel. got hand in a beam, and it healed nicely.

co2 as a scalpel. got hand in a beam, and it healed nicely.

so neat

so neat

![]() yup, tattoo removal lasers can be used for welding if the q-switch gets removed.

yup, tattoo removal lasers can be used for welding if the q-switch gets removed.

cheers

cheers

![]() cheers!!

cheers!!

yeah ebay cheap tattoo removal lasers :)

yeah ebay cheap tattoo removal lasers :)

stryropyro style

stryropyro style

![]() lasers don't care what they are used for. if you do not tell the tube it is for medical uses, it will happily deliver its scalpel-cauter like work.

lasers don't care what they are used for. if you do not tell the tube it is for medical uses, it will happily deliver its scalpel-cauter like work.

![]() blue laser works too, though I am a wimp and tried it only on a piece of ham instead of myself. (the CO2 test was accident.)

blue laser works too, though I am a wimp and tried it only on a piece of ham instead of myself. (the CO2 test was accident.)

![]() ...should try melting acrylic powder (eg. the nail-art material) into surface of clear acrylic.

...should try melting acrylic powder (eg. the nail-art material) into surface of clear acrylic.

![]() ...or cocoa powder into white chocolate.

...or cocoa powder into white chocolate.

heh

heh

![]() food shenanigans have the advantage that you can easily dispose of the fails. (and the successes too.)

food shenanigans have the advantage that you can easily dispose of the fails. (and the successes too.)

i wonder if i can slice pizza

i wonder if i can slice pizza

![]() wisconsin uni tried to cut cheese. turned out you need a uv laser for good cut, without melting more than cutting.

wisconsin uni tried to cut cheese. turned out you need a uv laser for good cut, without melting more than cutting.

![]() lasercut pizza will be on youtube. i think i saw it.

lasercut pizza will be on youtube. i think i saw it.

yeah its amazing how many folks think, laser, food lets try it .. our hackerspace had many varied smells

yeah its amazing how many folks think, laser, food lets try it .. our hackerspace had many varied smells

the fat

the fat

![]() how much cooling does the kilowatt machine need? how big/heavy it is?

how much cooling does the kilowatt machine need? how big/heavy it is?

it has a dedicated water color fan thing thats a decent size

it has a dedicated water color fan thing thats a decent size

i ahve some pics somewhere i think

i ahve some pics somewhere i think

![]() a water chiller?

a water chiller?

https://gweikecnc.com/product/107.html its a gweike, who pretty much supply most everyone these days

https://gweikecnc.com/product/107.html its a gweike, who pretty much supply most everyone these days

yeah it runs water to the head

yeah it runs water to the head

and relative size

and relative size

![]() sweetie!

sweetie!

the two tanks were the best we could get on a saturday of n2/o2 persuaded a local brewery supply shop to sell us them, but replaced them with much larger ones

the two tanks were the best we could get on a saturday of n2/o2 persuaded a local brewery supply shop to sell us them, but replaced them with much larger ones

![]() saw the oxygen separator zeolite beads on aliexpress. for pressure-swing separation.

saw the oxygen separator zeolite beads on aliexpress. for pressure-swing separation.

![]() could work for both oxygen generation and nitrogen-enriched stream.

could work for both oxygen generation and nitrogen-enriched stream.

yeah the o2 is very low pressure so that tank we've had since the start, the n2 though you go thru like crazy

yeah the o2 is very low pressure so that tank we've had since the start, the n2 though you go thru like crazy

![]() pressurize some air, then cycle compression-decompression through cylinders with the zeolite.

pressurize some air, then cycle compression-decompression through cylinders with the zeolite.

![]() electrochemical medical oxygen sensors can be bought (annoyingly expensive) too. going up to 100% o2.

electrochemical medical oxygen sensors can be bought (annoyingly expensive) too. going up to 100% o2.

n2 runs about 12 bar

n2 runs about 12 bar

![]() what is its role in the process? mechanical blowing off stuff from the cut?

what is its role in the process? mechanical blowing off stuff from the cut?

yeah we looked at medical ones, but the pressure and the amount they generate per cost, i think it was about 5K USD for one that makes a very small amount, so going with the rotary compressor with a fridge/dryer setup

yeah we looked at medical ones, but the pressure and the amount they generate per cost, i think it was about 5K USD for one that makes a very small amount, so going with the rotary compressor with a fridge/dryer setup

for o2 it helps it burn, the n2 shields

for o2 it helps it burn, the n2 shields

so deeper cuts/nice cuts

so deeper cuts/nice cuts

![]() there are also industrial ones. same principle, bigger size, no medical nonsense paperwork/certs/price.

there are also industrial ones. same principle, bigger size, no medical nonsense paperwork/certs/price.

yeah iirc the issue was the pressure

yeah iirc the issue was the pressure

![]() flow speed? as the pressure converts to speed in the nozzle?

flow speed? as the pressure converts to speed in the nozzle?

we found a chinese compressor for 4K new that can run upto like 25 bar

we found a chinese compressor for 4K new that can run upto like 25 bar

![]() not bad!

not bad!

tank pressure, since for the n2 upto a 3mm nozzle with 12 bar

tank pressure, since for the n2 upto a 3mm nozzle with 12 bar

so a 300 tank lasts maybe 12-15 minutes and thats around what 140 bar?

so a 300 tank lasts maybe 12-15 minutes and thats around what 140 bar?

![]() there are also membrane-based nitrogen separators.

there are also membrane-based nitrogen separators.

yeah we looked at a whole range of medical supply ones, they just didnt generate anywhere near enough for the cost,since medical

yeah we looked at a whole range of medical supply ones, they just didnt generate anywhere near enough for the cost,since medical

![]() a pair or three medical oxygen generators is sometimes used as alternative to bottled oxygen for smaller-scale glassworking.

a pair or three medical oxygen generators is sometimes used as alternative to bottled oxygen for smaller-scale glassworking.

like terra https://www.terrauniversal.com/portable-nitrogen-generator-2700-99.html

like terra https://www.terrauniversal.com/portable-nitrogen-generator-2700-99.html

![]() we had a big-ass generator for gas assist in a plastic moulding factory.

we had a big-ass generator for gas assist in a plastic moulding factory.

so like 6 scfh

so like 6 scfh

yeah this is what we bought

yeah this is what we bought

![]() like with an electric car battery, you could have a nitrogen production unit running 24/7 and feeding a tank and taking out of the tank as needed at higher flow than the generator would give.

like with an electric car battery, you could have a nitrogen production unit running 24/7 and feeding a tank and taking out of the tank as needed at higher flow than the generator would give.

three phase, 15HP, just have to find a place to put it

three phase, 15HP, just have to find a place to put it

![]() a second floor of the garage. :P

a second floor of the garage. :P

![]() or a basement under the garage.

or a basement under the garage.

i think its going outside in the garden heh, no basements here

i think its going outside in the garden heh, no basements here

![]() bad geology?

bad geology?

yeah northridge, earthquakes, liquefaction zone

yeah northridge, earthquakes, liquefaction zone

![]() yuck.

yuck.

yeah you know its bad when you live in a place that has a quake named for it

yeah you know its bad when you live in a place that has a quake named for it

![]() fun! get shakin'!

fun! get shakin'!

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.