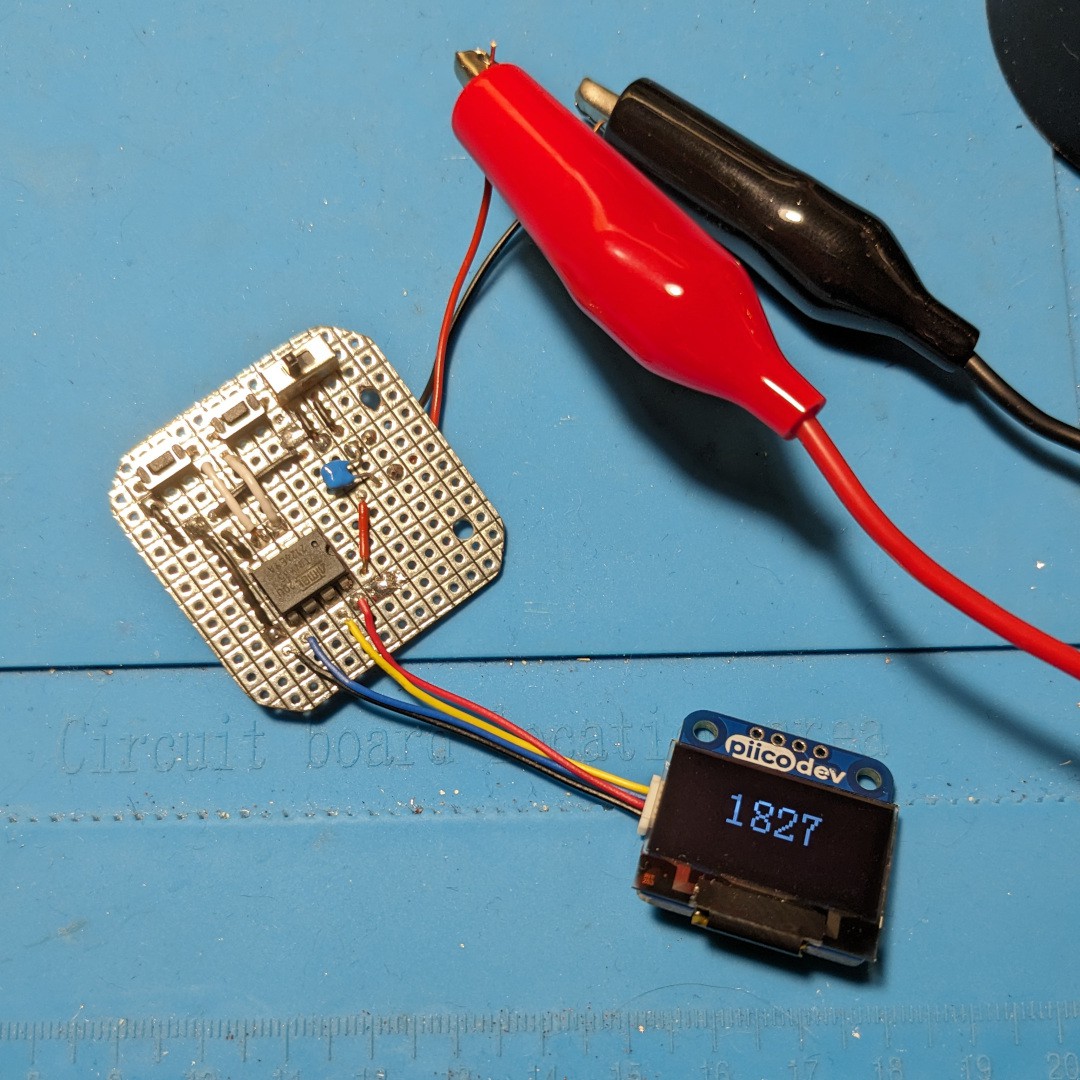

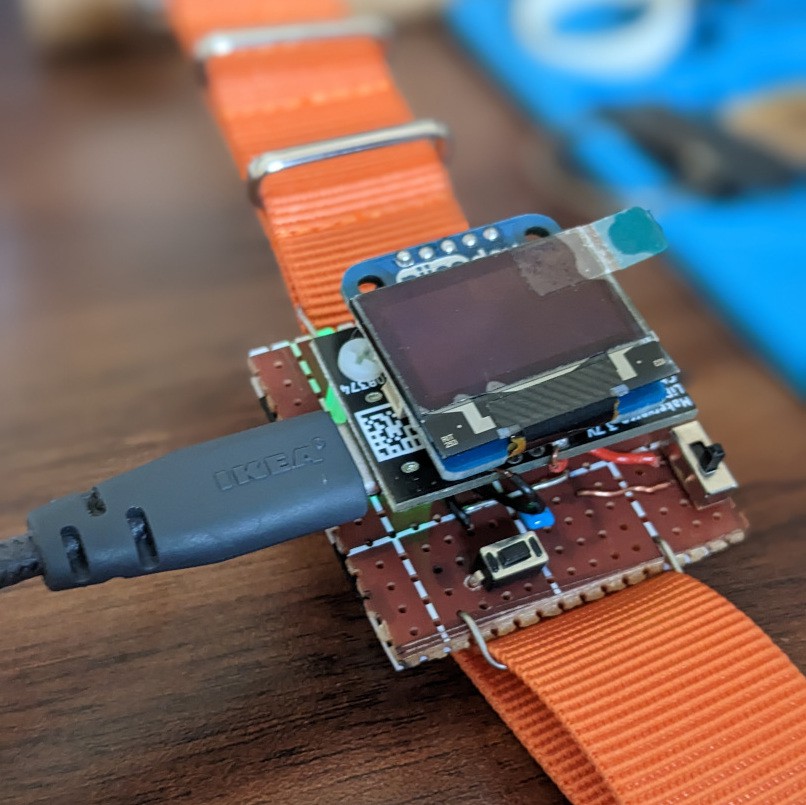

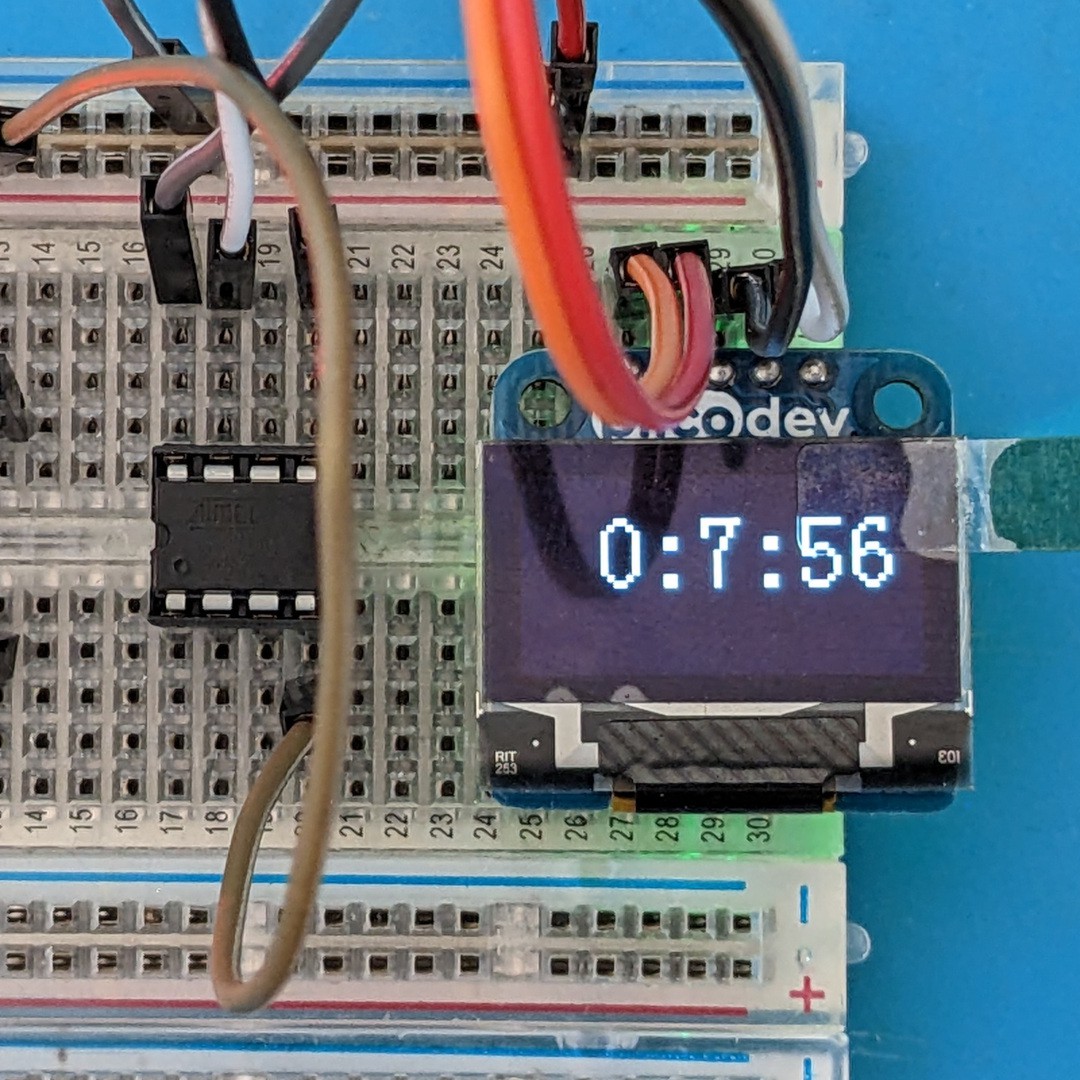

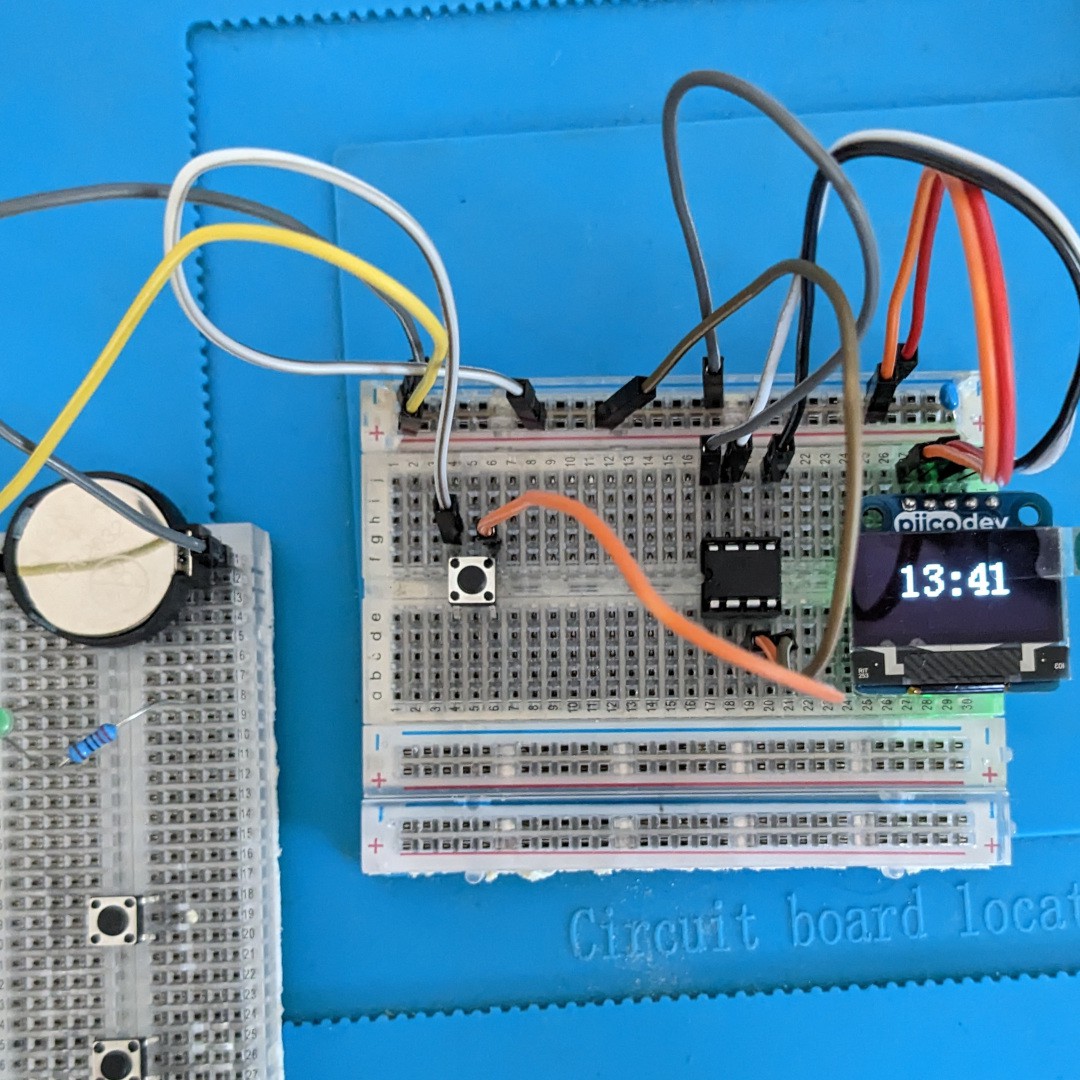

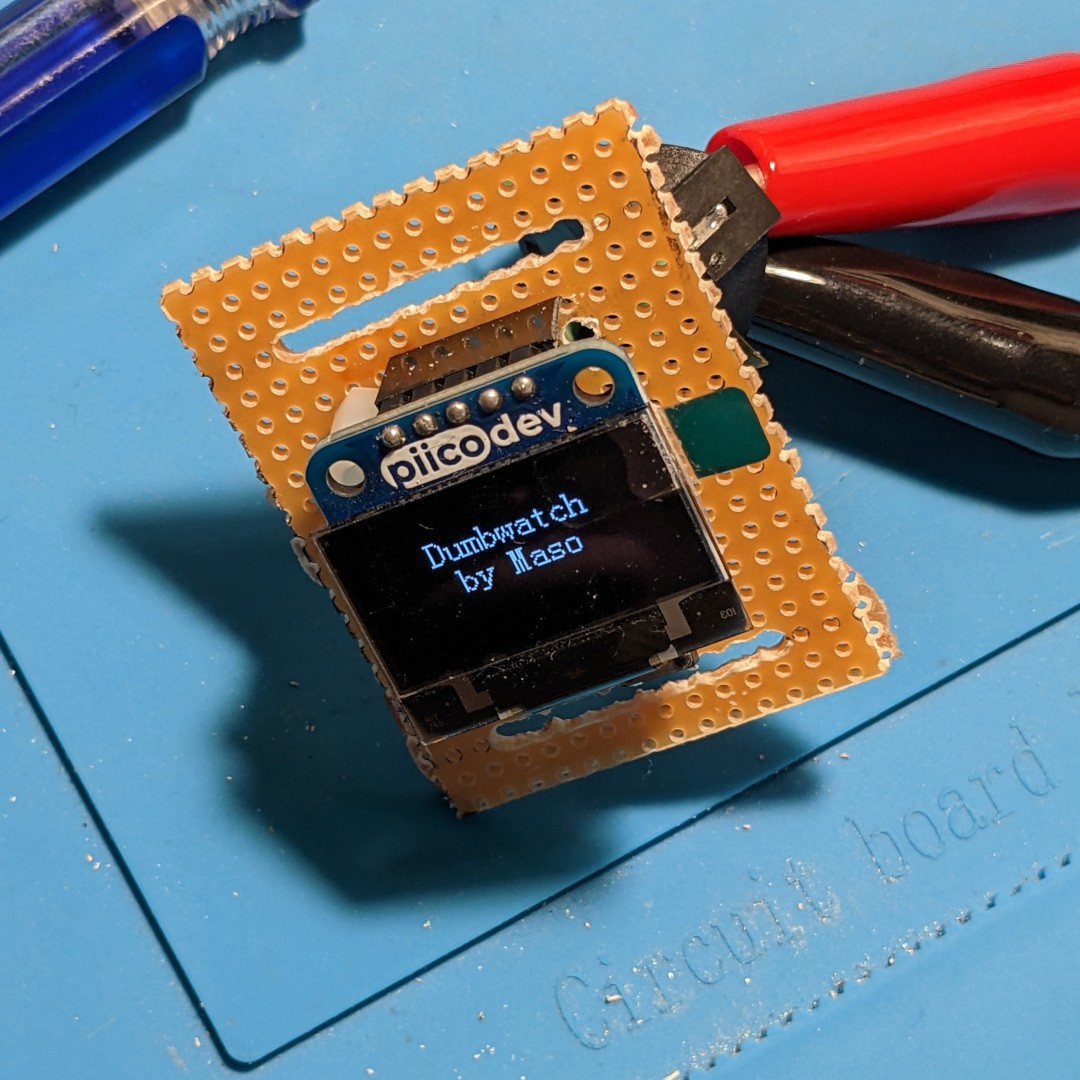

This ATtiny85 based timepiece is an exercise in making the most minimally viable (not accurate) timepiece possible. Building on the I2C OLED/MCU combo of the previous version, this upgrade makes the important distinction of being functionally wearable with minimal fuss.

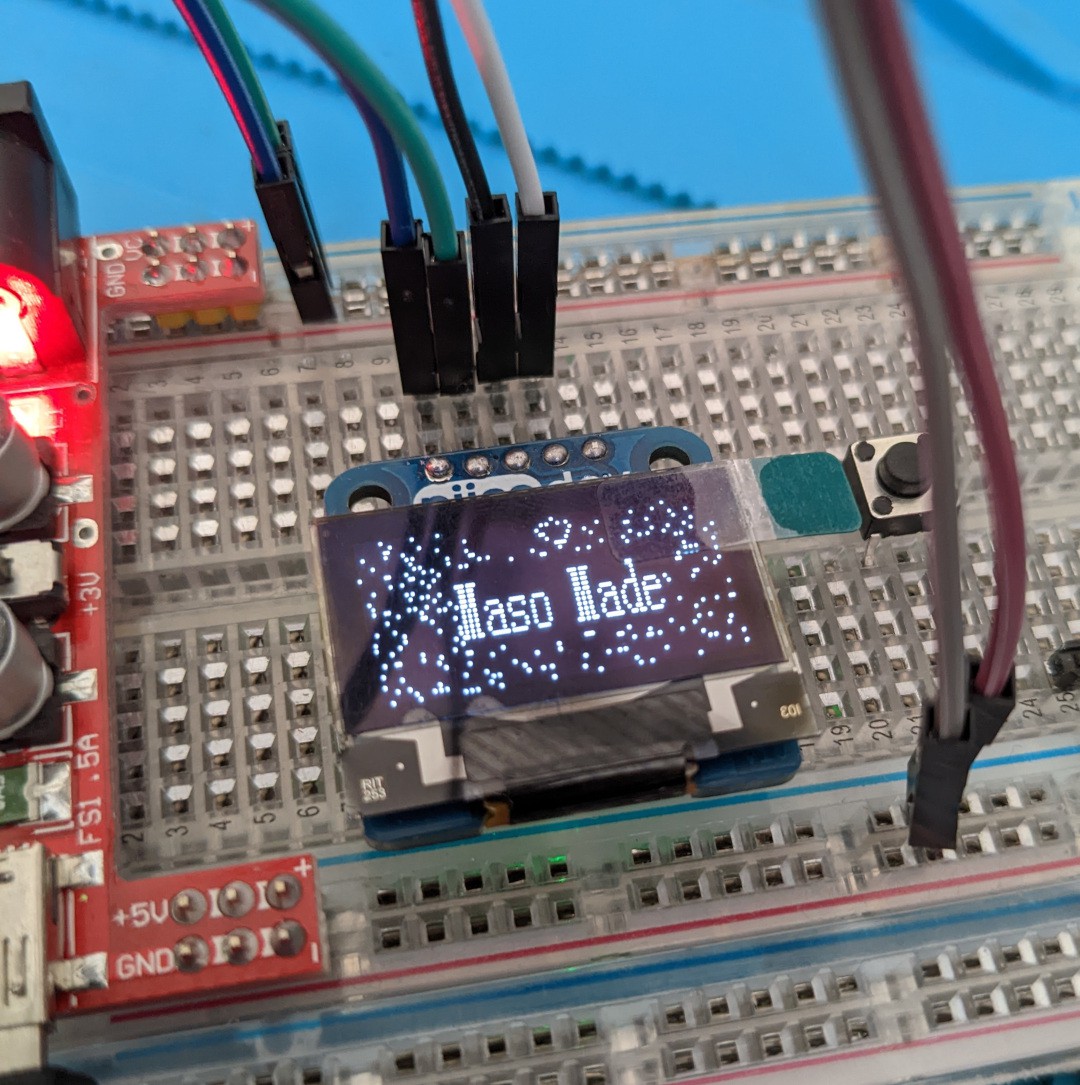

In it's current form, the watch time is manually set with a single tactile button located just below the display.

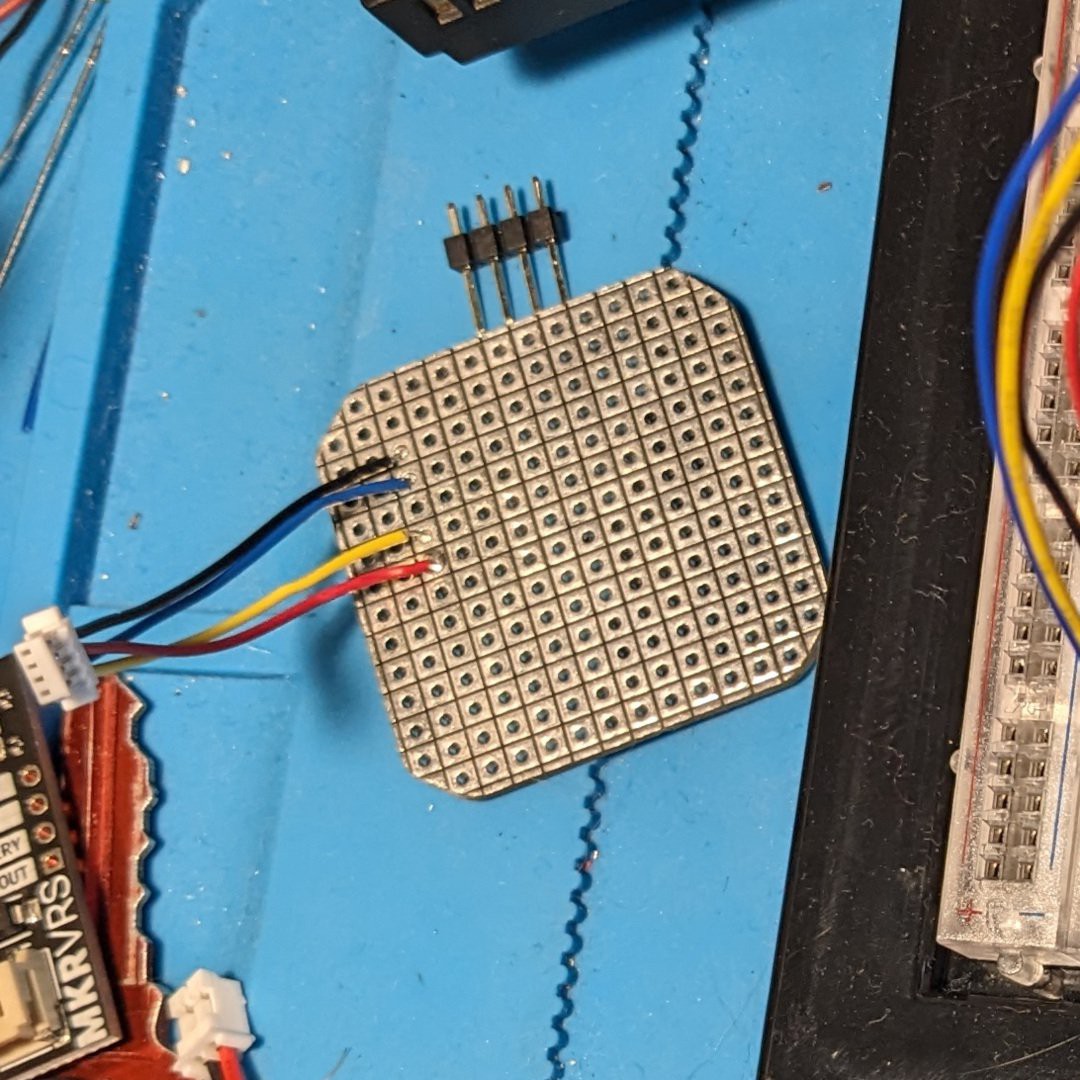

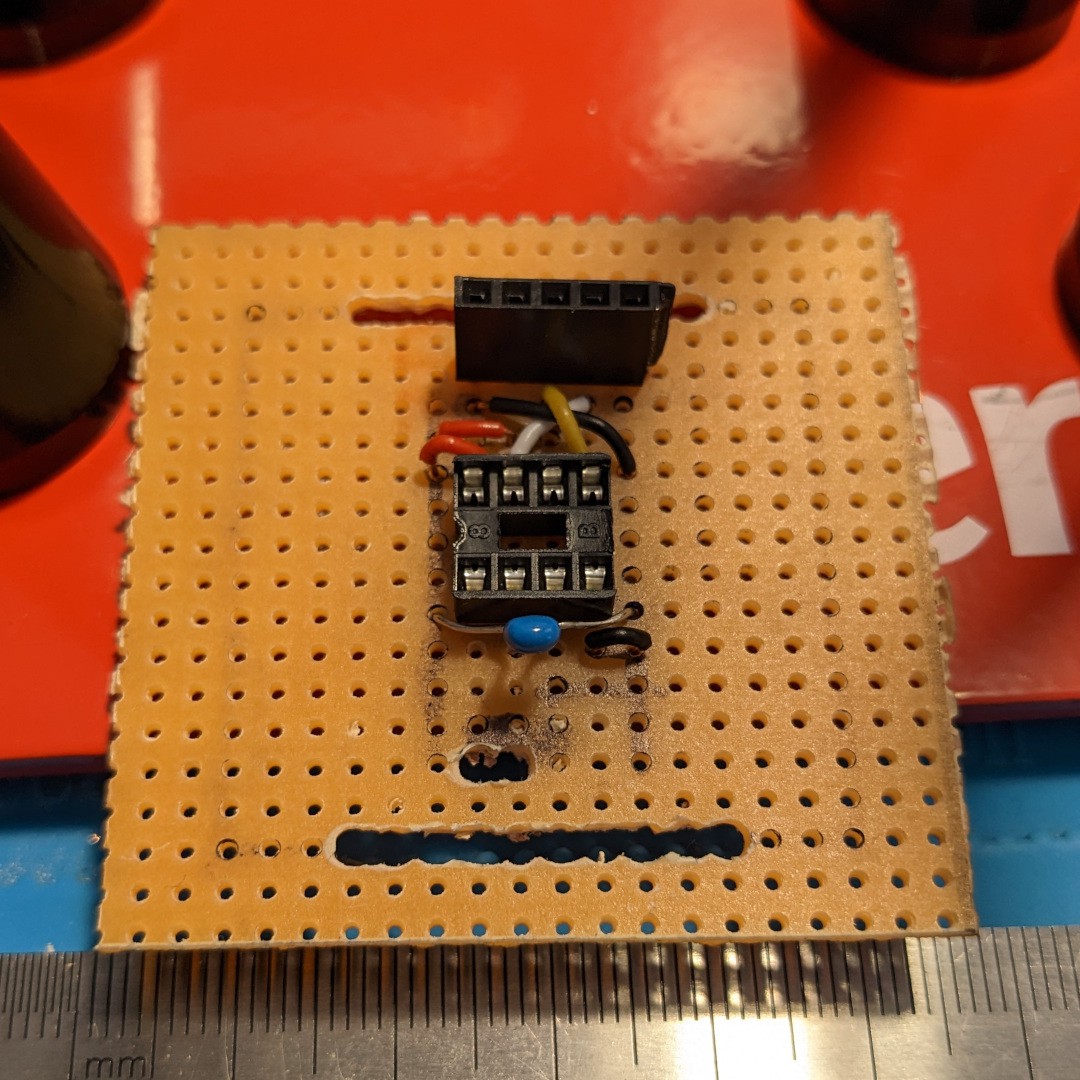

This watch is built with the intention of being a base to iterate new revisions as easily as possible. Hence, the OLED and ATtiny are socketed making it easy to flash new firmware and possibly swap out displays.

Maso

Maso