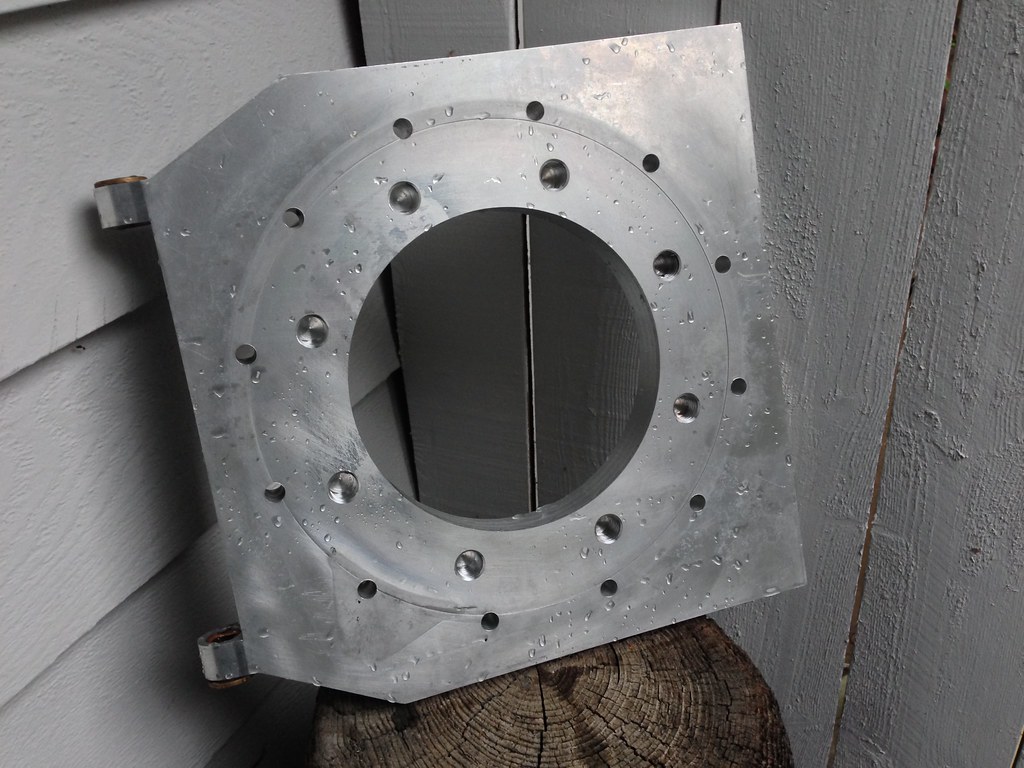

I got a piece of aluminum from a friend for the next part of the adapter, this was an lid from an old plasma etcher. Its a piece aluminum about 14x14 and 1.25" thick. Pretty perfect.

I decided to leave it square, no reason to make it circular in the greater scheme of things. Milled out the chunk in the center leaving the core for the base for the telescope. Spotted and drilled all the holes, 7/16" on the small ones and 5/8" on the large ones. Had a little fun with the 7/16" ones, had a bit explode on my when I lost coolant. Oops.

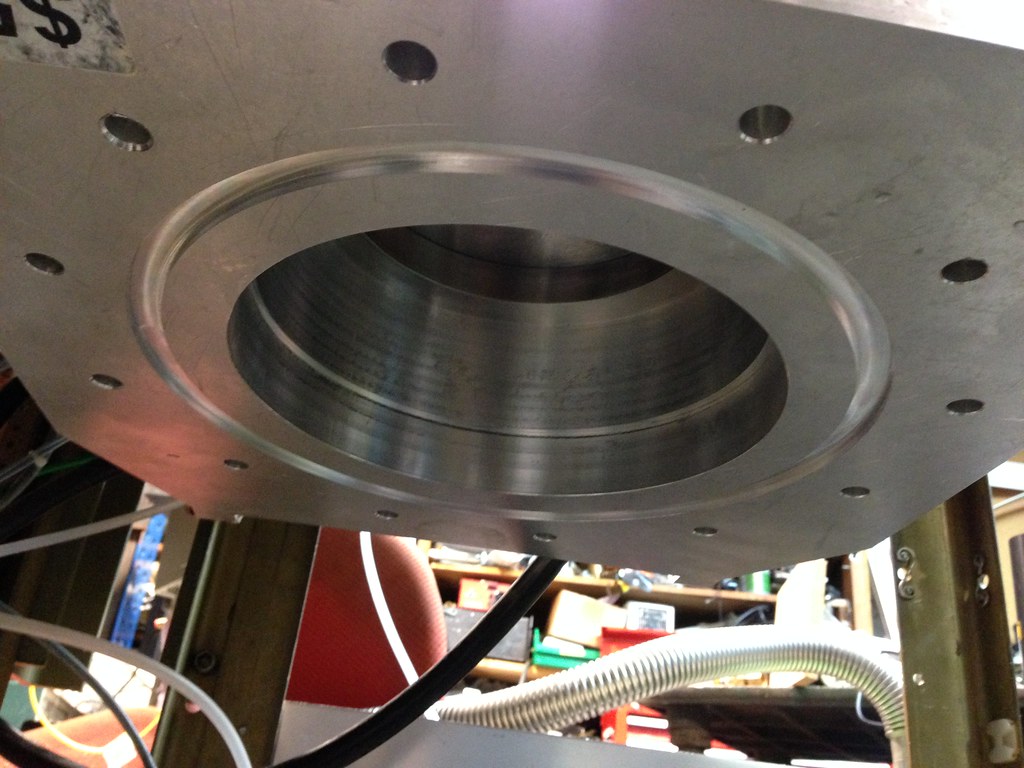

The 5/8" holes were cleaned up with a mill and then thread milled to 3/4"-10. This was my first attempt at thread milling, one goof and a $80 bit is toast. But it all worked out and had nice, straight threads in a blind hole all the way to the bottom.

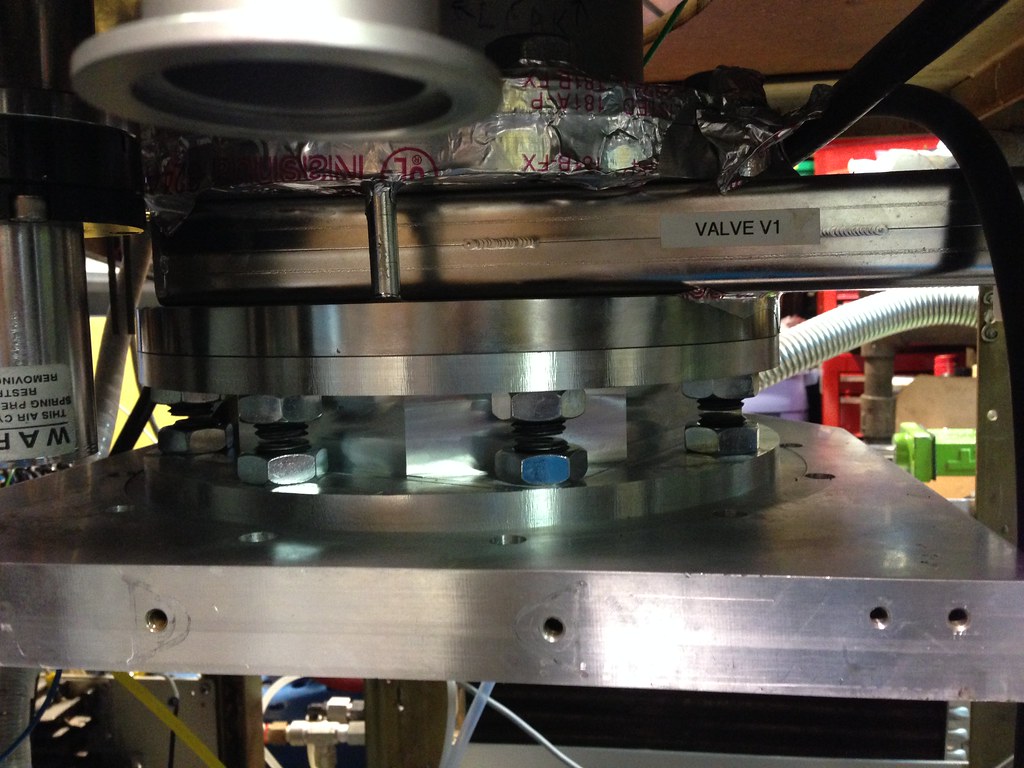

After that I cut a groove for the centering ring/seal for the ISO side. I had ordered some new o-rings, 3/4" threaded rod, and half nuts from mcmaster which arrived today. I cut up the rod on the lathe and bolted it all together. Here's hoping it does not leak!

Next up is to clean up the gate valve that is going to hang off this adapter and then hand it. Both the gate valve and the turbo are 150lbs each so I need to figure out a way to get them up in place. I am thinking a hydraulic motorcycle lift.

Jerry Biehler

Jerry Biehler

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.