When I started these around the start of the year I just wanted to get a basic pivot design and see what kind of weight it would need to be to fly with some tiny cheap motors.

Seems like there are some 2s 7.2v 0820 coreless motors. but the set i ordered are 15000kv. so 3.2v rated at 49krpm.

Anyways I made a simple test stand, realized I could connect a motor module directly.

- v1 - Small taper design - 1s lipo = < 6g

- v2 - Larger intake taper (about 25%) - same battery = > 21g!

- This means for one the duct design is very very important!

- basic sanity check means 21g x2 = 40g max excess thrust

- so the whole heli should weigh less this for good handling/low batt flying.

- The test stand shows each motors thrust - (module weight) since it is balanced.

- Motor + duct (v2) + prop = 12.85g = 13g.

- "Test" electronics about 13.5g

- battery 11.5g

- servos about 4g each

- = 33g + Printed frame. = no flying yet...

but if v1 -> v2 can get 350% increase maybe I can find another 10g of thrust per motor?

guess I will print a ductless motor holder to see what the baseline is...

While I was waiting for the print I modeled a rocket nozzle from October Sky...

printed ok but not perfect, sound change but maybe something there...

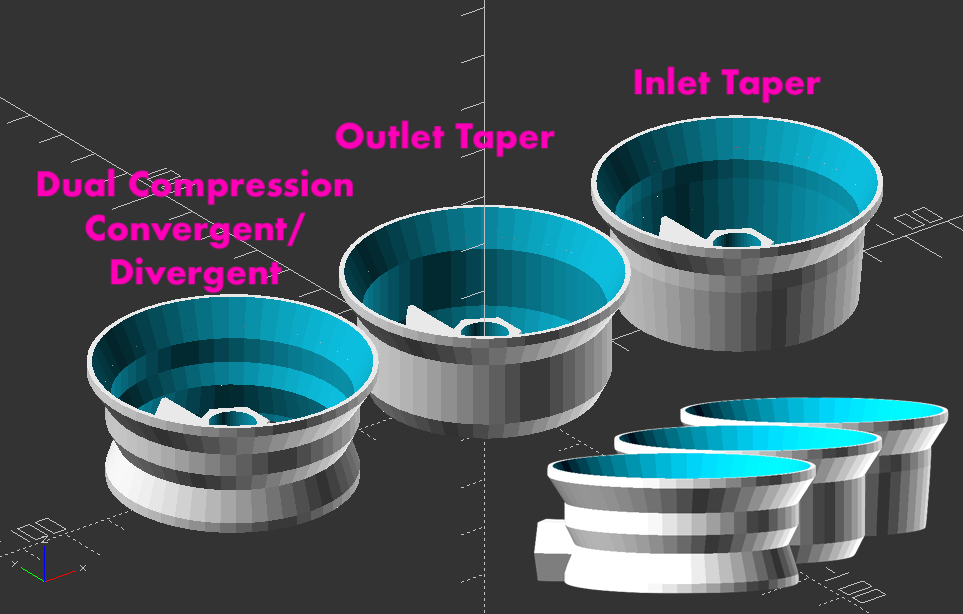

Edit: 2 more Duct Variations.

- single taper (cone section)

- Inlet taper + 2 mm negative taper on h/2

- inlet taper + cylindrical middle + 4mm negative outlet taper

- inlet taper x2 + Positive outlet taper. (integrated convergent/divergent)

Theres also variations based on inlet increase vs over taper.

A1V1 = A2V2

will probably try to curve the profile as well. im sure that will help when this hardware becomes a plane...

Saul

Saul

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.