Motivation and other existing solutions:

If you have a practical usecase for any kind plotter this project isn't for you. Unlike with 3d printers where you might argue that a $1000 voron in some categories outperform commercial offering at similar price category, the market for various kinds commercial plotters and vinyl cutters is much more mature.

Small size (~300mm work width) vinyl cutter costs $150-$500 and should have good performance and reliability in a user friendly package. Should work great for small size vinyl cutting and other crafts projects.

Large size (500-1000mm) vinyl cutters. There are models available in the $300-$1000 range. Might not be the best thing out there but probably still better than any DIY solution. Less suitable for misc crafts projects. While the price is still somewhat accessible there is little reason for hobbyist to buy one unless you have very specific needs.

Hanging plotter designs. Very simple and cheap to make, large working area. High spped and acceleration may cause the tool to swing around due to being partially constrained by gravity. Unless very carefully designed positional accuracy might suffer as the amount of string on spools vary. Very compact when not in use.

DIY and semi DIY pen plotters with cross or H style X/Y axis. In some categories one of the better options for plotter art kind of stuff. Can be relatively simple as a DIY project. Making the tool reliably move (for a DIY devicee) in X, Y direction is much easier than any kind of roller based system. Also not a bad option for medium/large size plotter art stuff. Probably the biggest downside is that it takes as much table space as the paper you are drawing on. Although when not in use cross style designs like Axidraw can be somewhat compact, might be even possible to create one which easily disassembles or folds when not in use. Since the paper isn't moving as long as steppers don't skip steps (which shouldn't be a problem for reasonable speeds) there shouldn't be any shifting during drawing. If necessary you can lightly tack the corners with little bit of tape. No risk of smudging from the rollers even if you are using slowly drying ink. No fussing with cutting mat being too sticky or not enough sticky, or paper jams. Unlike roller based systems thickness of paper shouldn't be a problem, both very thin and very thick paper should be fine.

How is this project worse than everything listed above:

In terms of cost this project is probably more expensive (at least when taking into account money spent on iterations) compared to all the commercial solutions listed above.

In terms of performance and ease of use, one of the 3 options above will probably be better (assuming you know your usecase).

Reliably moving paper back and forth with rollers isn't easy. I am still fighting with occasional shifts and some kind of backlash like direction dependent offsets. Also thinner paper without a backing mat tends to bunch up or otherwise crumpling. As much as people like to laugh about inkjet printers being unreliable, I am starting to feel much more respect for their designers.

Top rollers introduce risk of smudging the drawing.

Initial design goals/wish list:

- be able to draw on A2 sheets (at least with thicker materials) ✔️,

- be able to work with material from rolls (at least with thicker materials) -> not tested

- 25 inch width -> should fit ✔️,

- be able to work with thin <80g/m2 paper without cutting mat -> unclear whether I will succeed in this

- no 3d printed parts -> ❌ failed

- usable for cutting vinyl stickers, paper and thin cardboard ✔️,

Future posts TODO:

More detail descriptions of current design and early failed iterations

Cleanup the CAD model from third party components with unclear licensing and publish it

Software

Demonstration of test output

- BOM

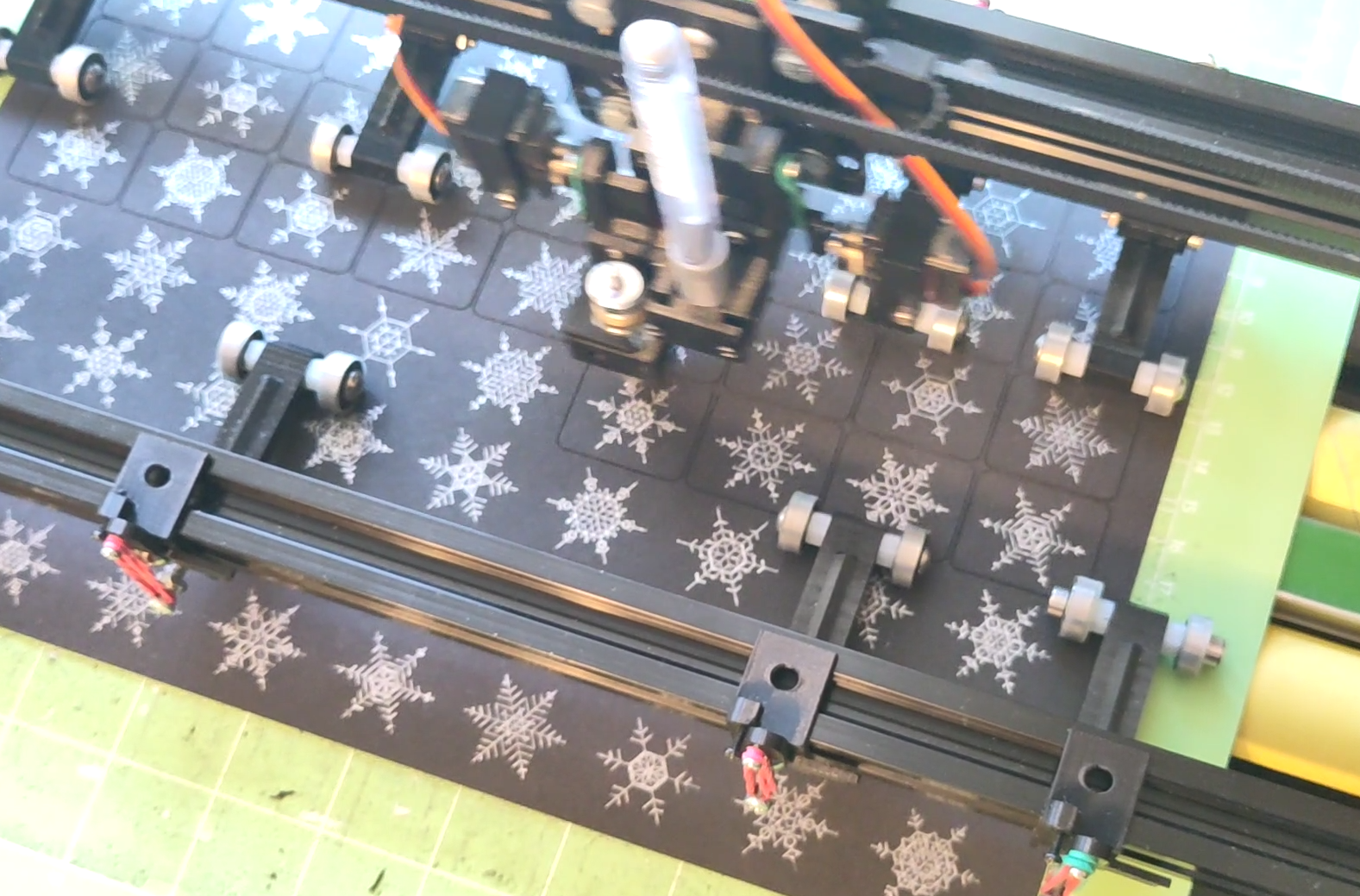

Bonus picture. Drawing and cutting a devilish winter themed memory matching game. Snowflakes generated using tool made by https://revdancatt.com/

Kārlis

Kārlis

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.