I designed a simple USB micro breakout PCB for my programming needs. Suffice to say this project is going to need a lot of firmware updates, and I'd like to do that on my laptop "out in the field". Since the project is meant to be installed into the tiller assembly, I'll need a way to reprogram / update firmware without tearing it apart each time.

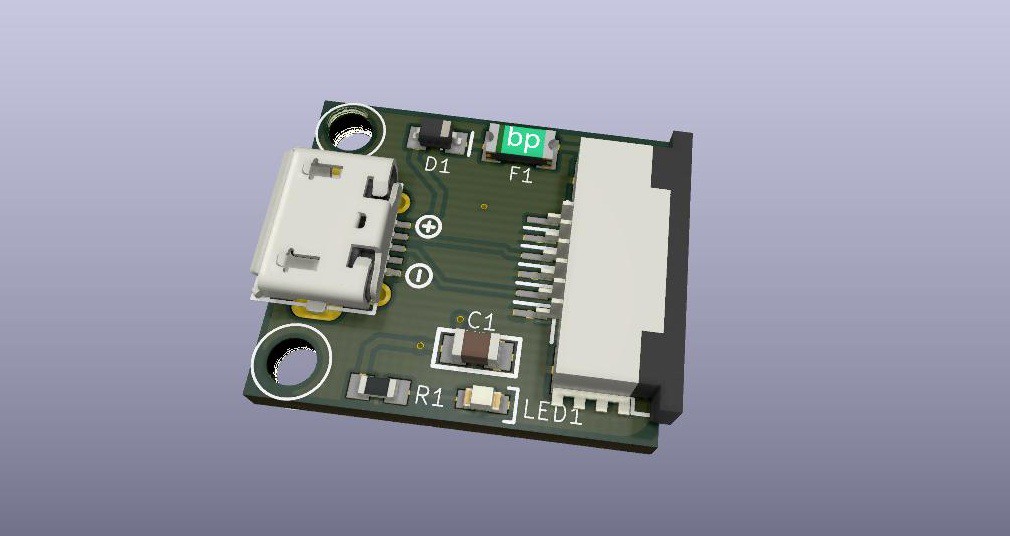

There's nothing too fancy here, just a diode to prevent power feedback, a PTC fuse, power LED, and decoupling cap. I probably should have included a spot for TVS diodes (transient voltage suppressors which absorb voltage spikes) but I've honestly never had a project that needed them and I can also add em to the main MCU PCB down the road or update this one later on. Optimizing this project for speed at the moment!

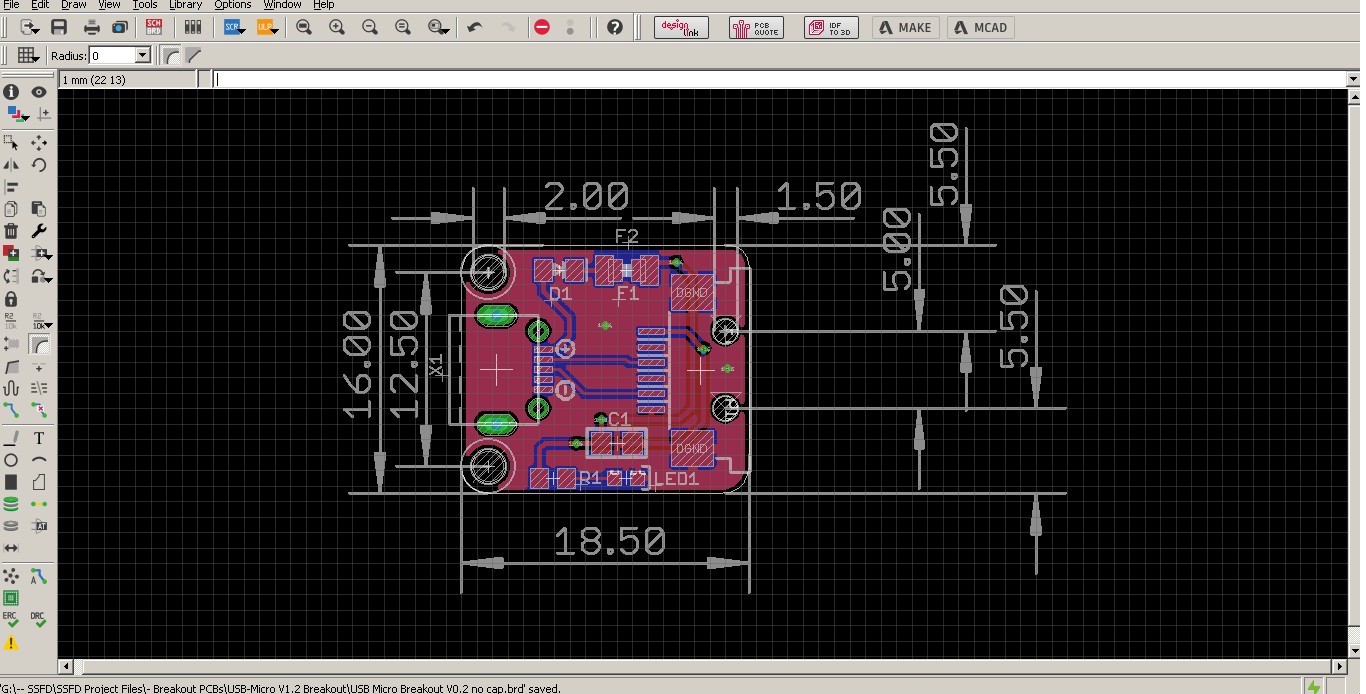

I did get creative with one thing here though - 2x secret cutouts under the FPC connector. I can model the mount this board goes in to take advantage of those holes for some sneaky structural support while keeping it still at only 2x screw mounts :)

This micro PCB will eventually be enclosed in a custom panel mount 3D printed enclosure. Ive designed these before, and they come out very nice. It's always a shame to me that more panel mount parts aren't produced these days, as so much has been streamlined for a waste economy of large scale manufacturing. Anyone remember all the cool panel mount jacks they used to have at Radio Shack and such?

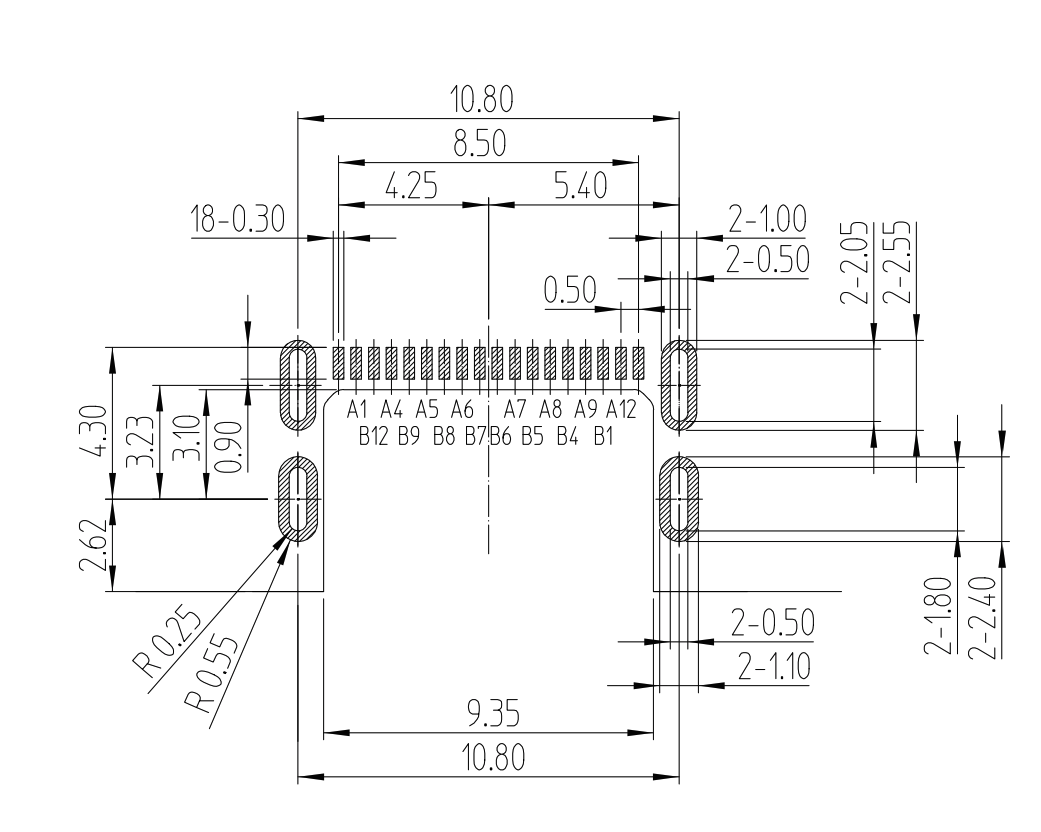

I went with micro USB since the footprint for USB-C is a frustratingly small pitch:

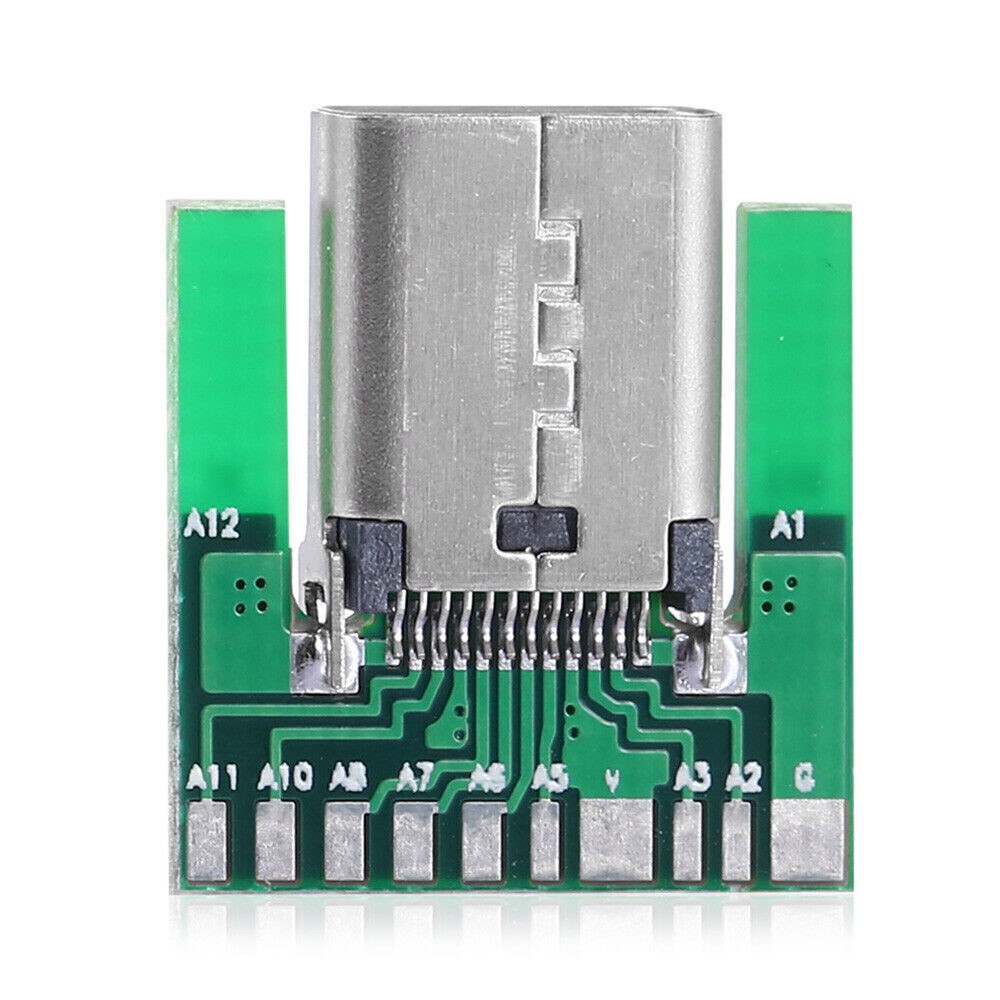

Even the breakout kit resorts to an edge mounted jack, because of how fine this footprint it. Seriously, look at the land pattern spec:

This is a standard right-angle PCB mount USB-C connector. You see that pin pitch? 0.30 milimeters! That is significantly finer than QFNs or TSSOPs (0.50mm/0.65mm). I mean c'mon, that's just cruel and unusual punishment to the hand-solderers out there!

So yeah, USB-C programming is a breakout-only affair for my home manufacturing for now. Thus, the old reliable USB Micro :)

[to be continued...]

CriptasticHacker

CriptasticHacker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.