For the single M3 grub screw that actually went all the way in, it looked fine.

For all the other ones tho...

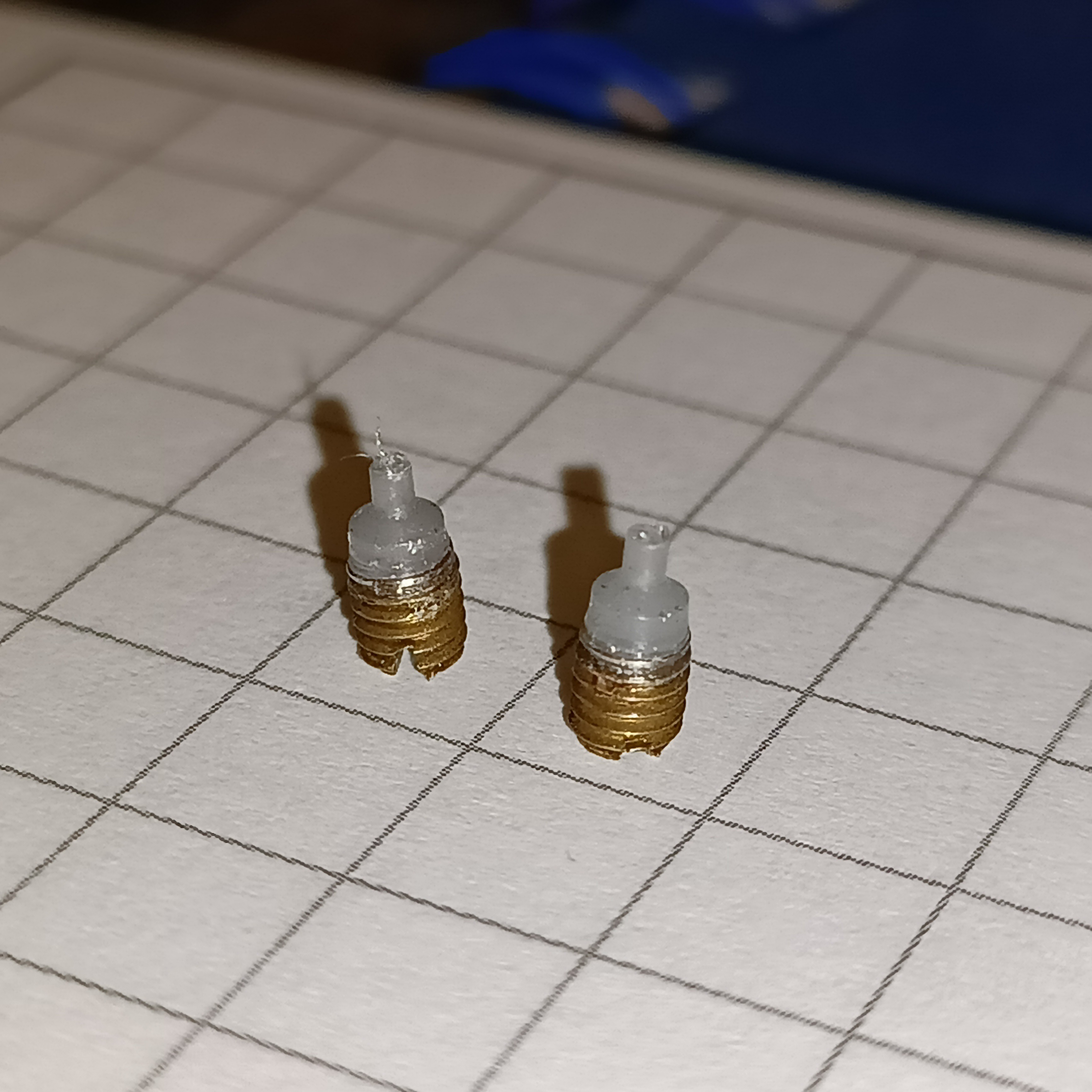

Some screwed out with plastic:

Some screwed out with plastic remaining in the hole:

And some didn't budge at all and it looked like I could risk breaking the M3.

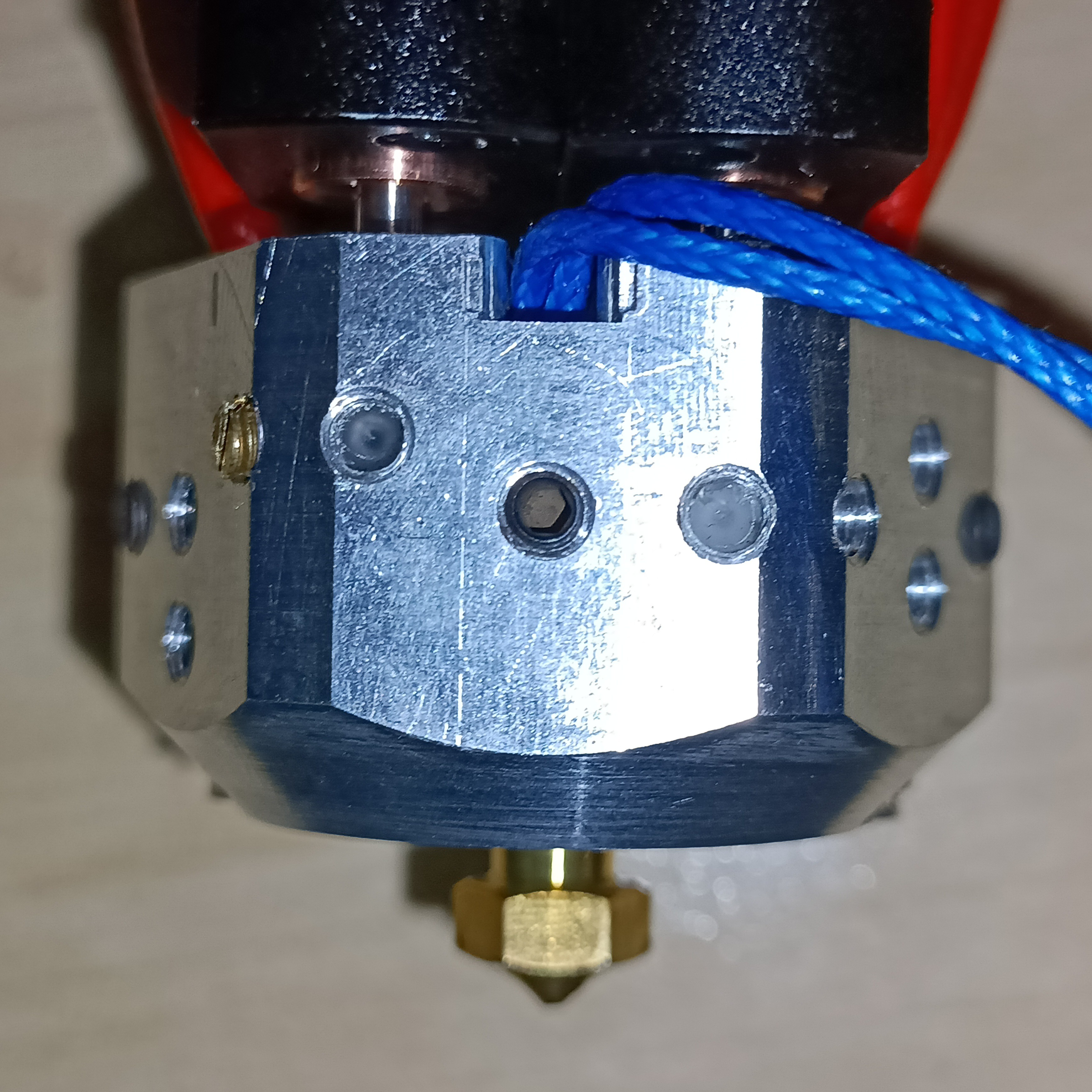

I'm thinking that the small size of M3's are unsuitable for this kind of work. I'd imagine that M4's would be more reliable, and they certainly can handle more torque. The hex M4 grubs that hold the heatsinks seem sturdy enough.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.