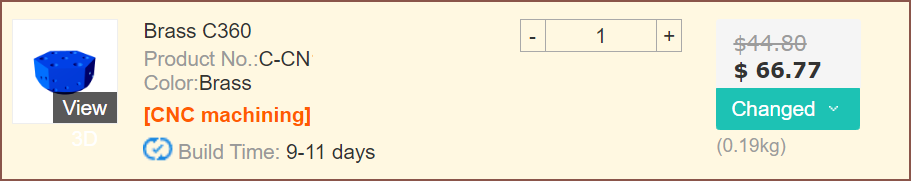

So, to recap, here's where I started:

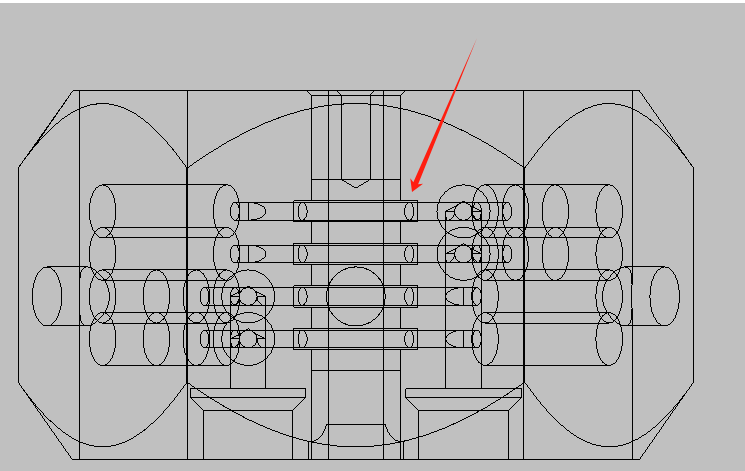

That fell through because there was a lot of improvements that needed to be made, and when I went back:

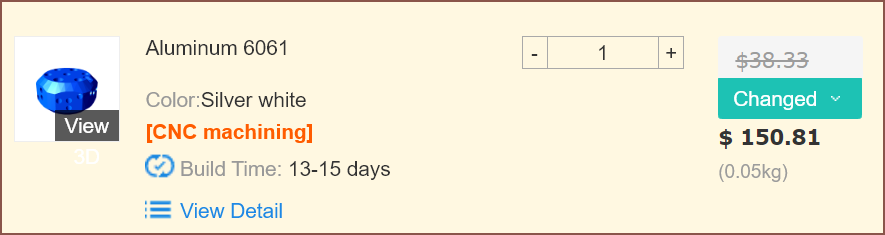

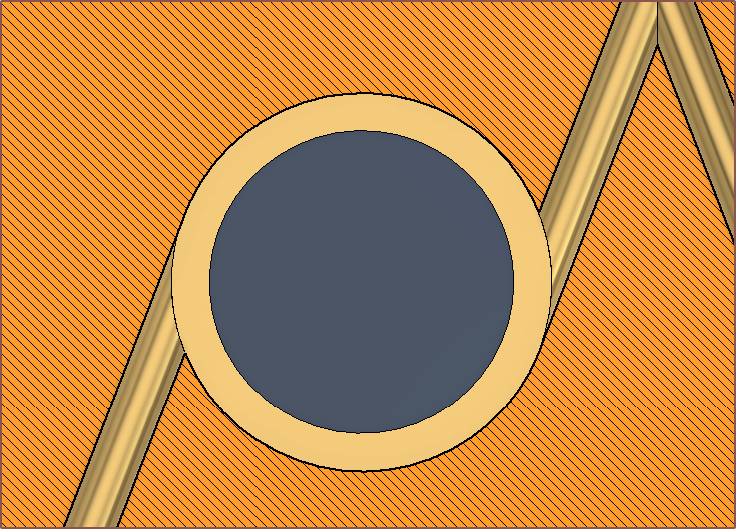

So, obviously, I was like "If I'm paying that kind of price, I should make sure it's the best it can be", thus I designed a version with my off-centered idea that I never got quoted. I then decided to model and send the 8-in-1-out version:

That fell through as that's when my subconscious price limit started to kick in, especially with the more expensive heatsinks needed.

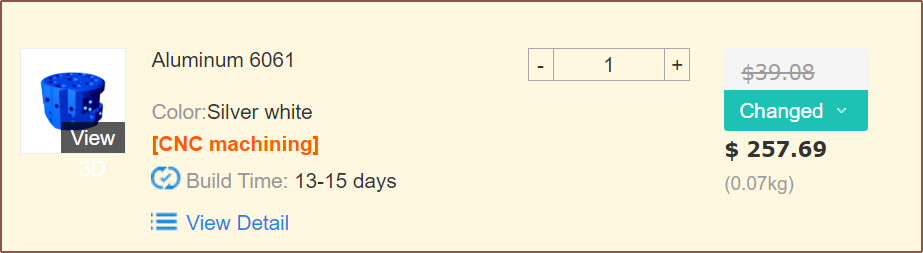

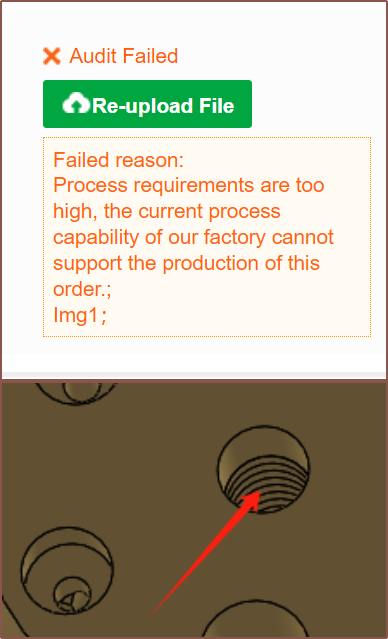

Now it's today, when I realised that I never got that 4-in-1-out off-centered design quoted. This was also the first one that featured the stainless steel ball-plugs over the grub screw design. Well I sent some variants through and I got this:

I'm like "Okay...? This is new." and send in a version with a 6mm internal bore (like the 8-in-1-out) and reduced the groove depth from 1mm to 0.75mm just in-case:

The result?

I can only assume that the workers checking the 3D printing / CNC files at PCBway have become more perceptive over time, better detecting unconventional geometry? Or maybe it's the "Spring Festival" tag, which I haven't seen before? I've never seen an over-20 day lead time before.

Maybe a better strategy for the Milled Coaxial Hotend is to see if I can get into contact with Mellow about this? Otherwise, the Printed Coaxial Heatblock is likely going to have to be good enough for science (if the 4-in-1-out machined heatblock I've got has an issue or I feel the need for more inputs).

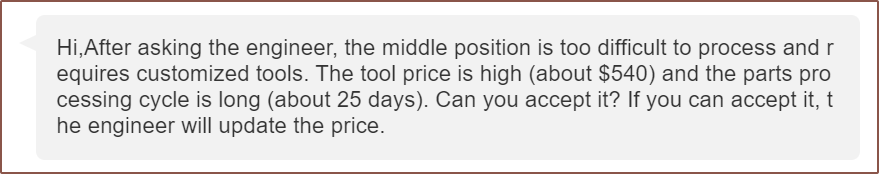

[07:40] I got more details. Seems that it's a tooling issue:

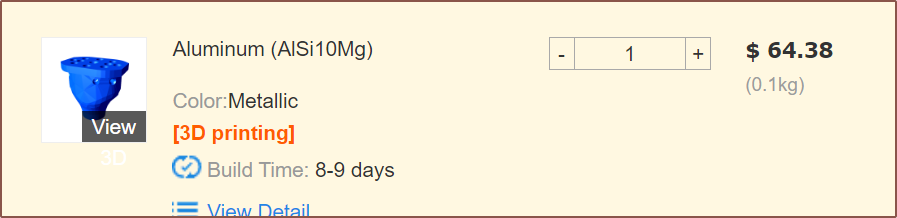

[0810] A rough estimate model of the 8-in-1-out printed heatblock is $64:

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.