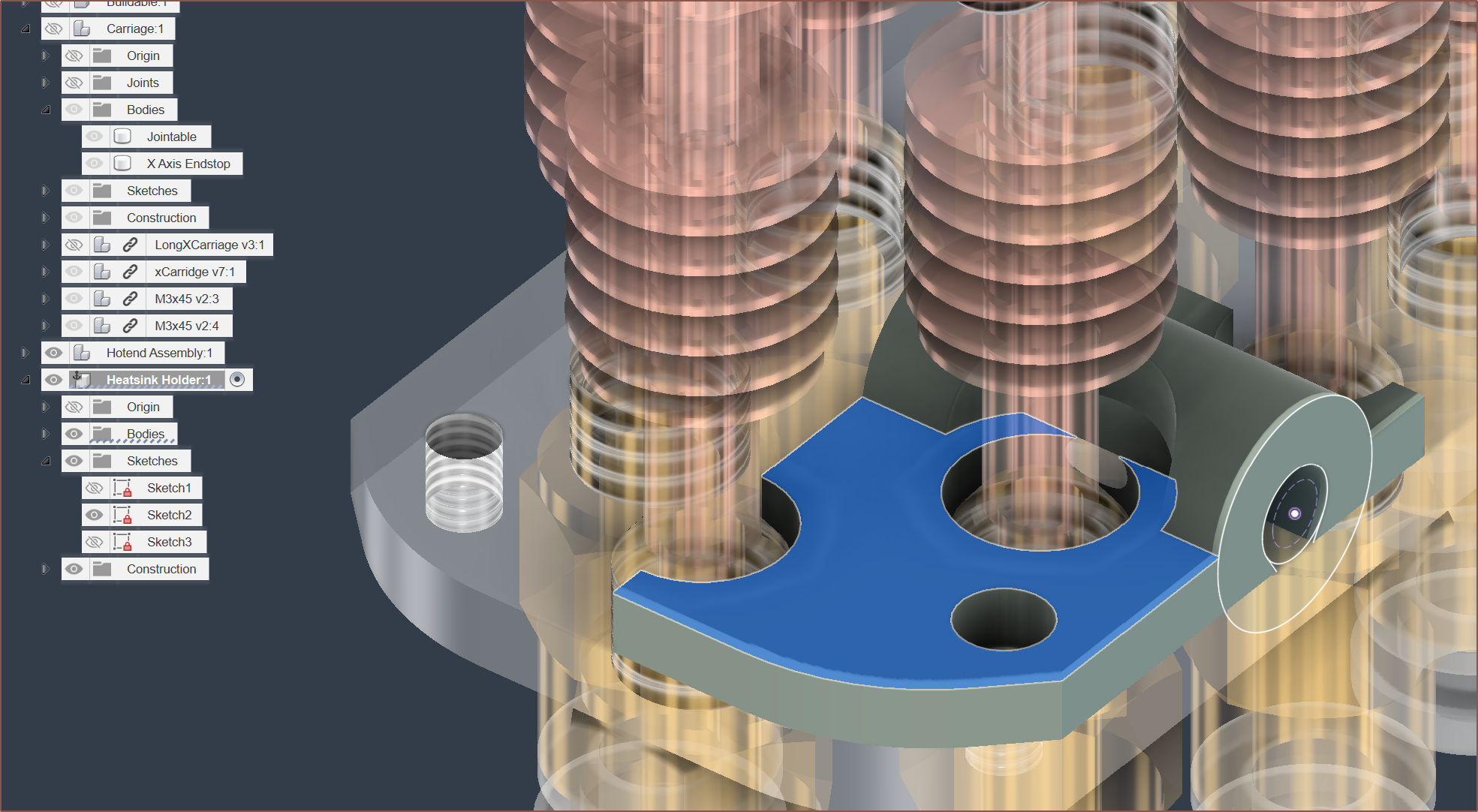

I've decided to rename the "hotend holder" to "heatsink holder" since that is more accurate.:

As you can see, I've had to change how I design the holder because I need to take into account the size of the allen wrench.

Anyway, following on from the previous log, putting the heatsinks into the bowden couplers was such an ordeal that I decided that I was going to redesign the heatsink holder instead of run a new test print.

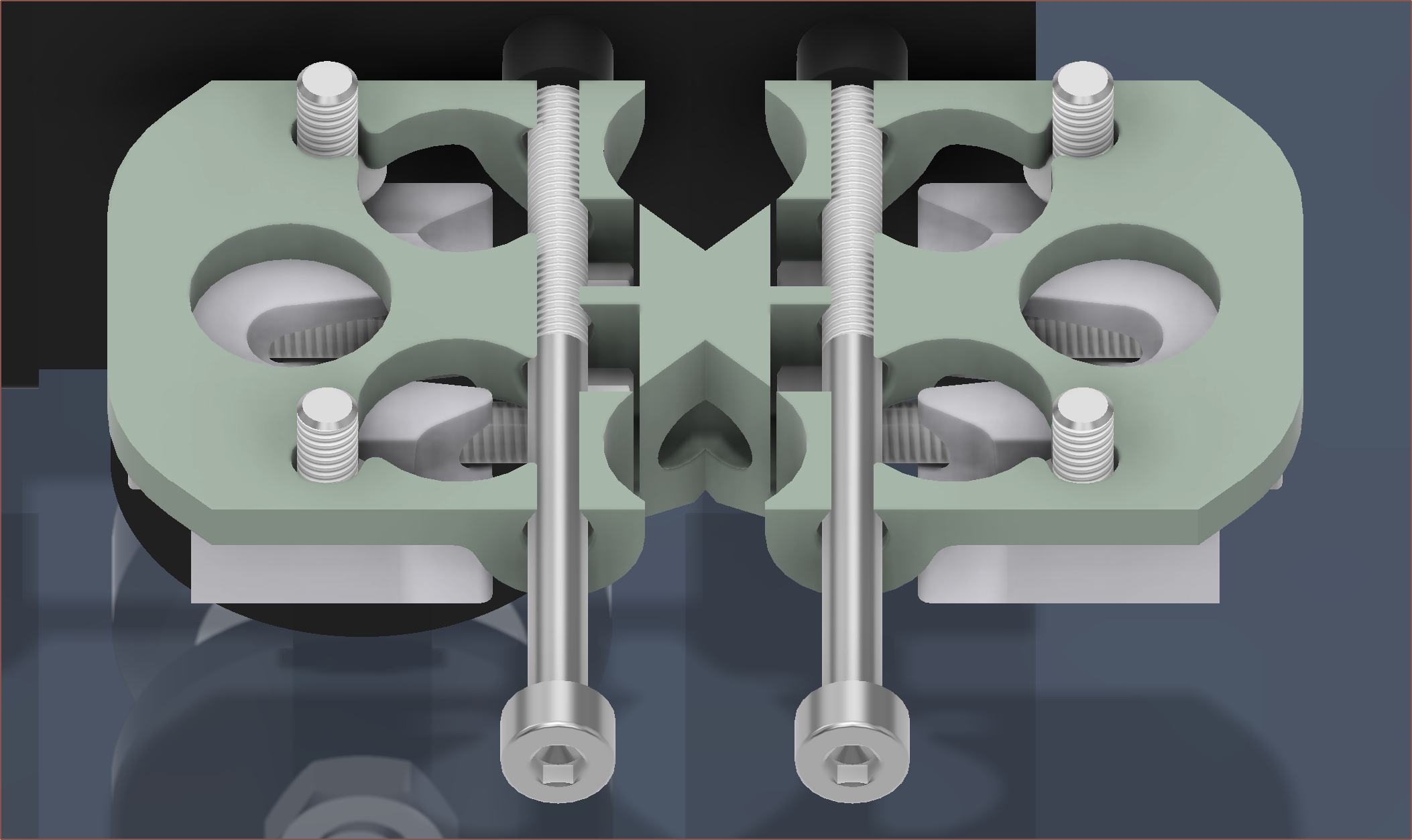

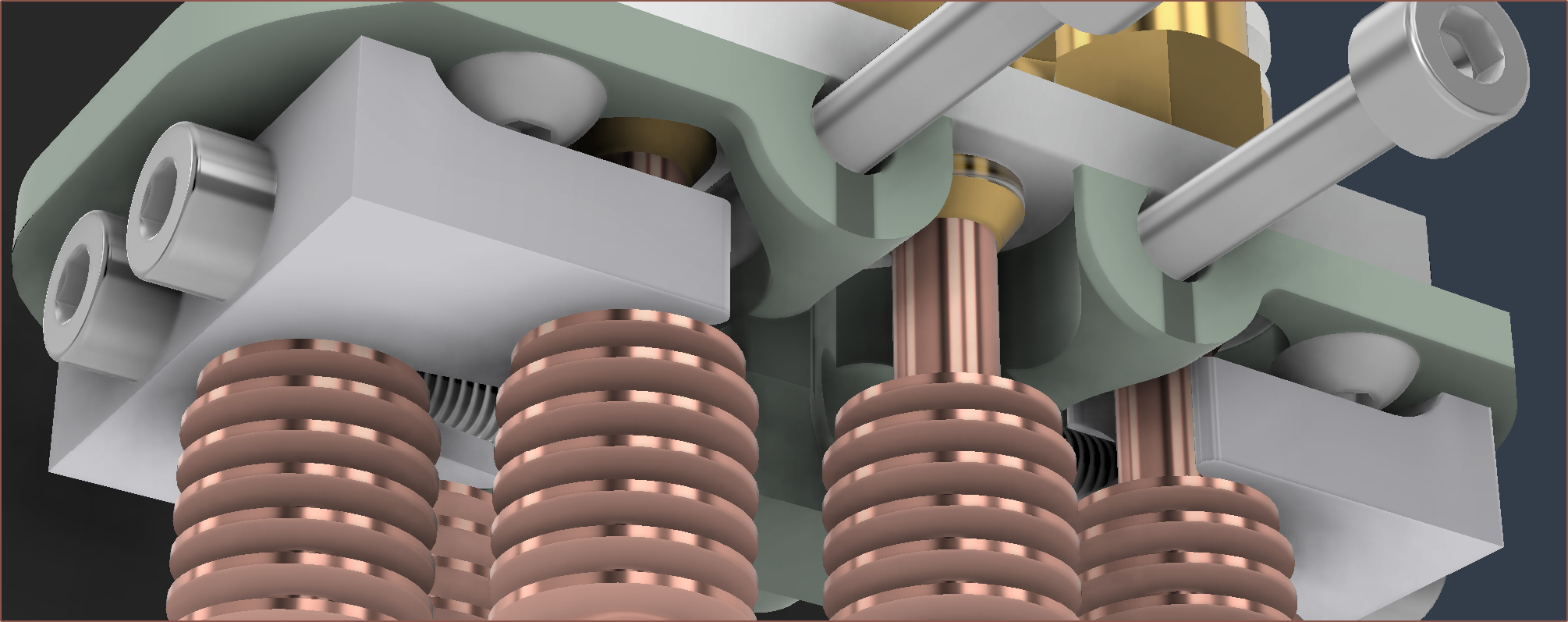

It took 3 hours of thinking, but I was able to arrive at a solution that doesn't have any geometric intersections and allows me to have full access to the heatsinks before installing the assembly to the holder:

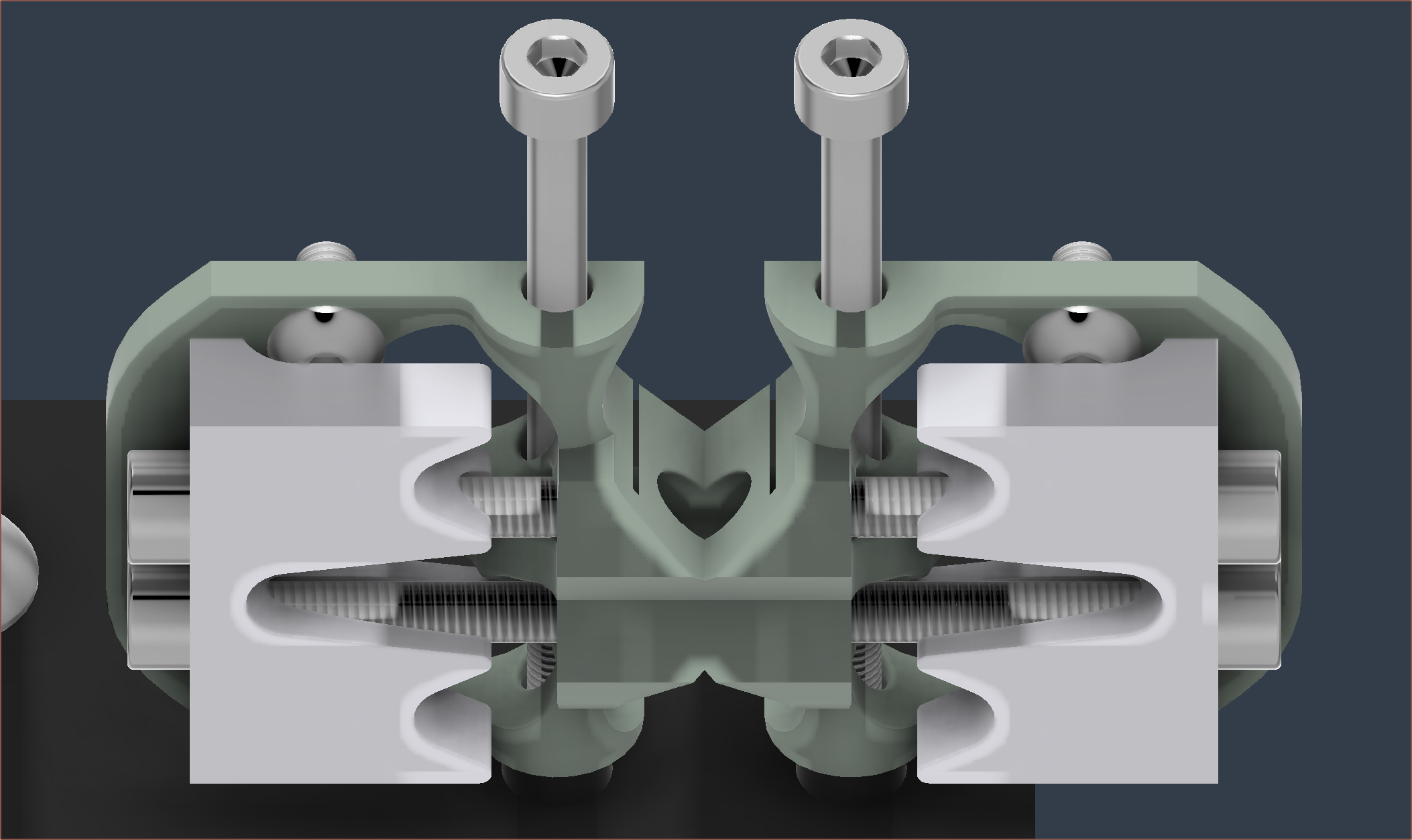

The hope is that the aluminium plate provides stiffness and the white parts clamp the heatsinks with enough force that they stay in place. I don't know if a printed part will provide enough friction, but if it works it means that I no longer have to damage the surface of the copper with the grub screws.

The hope is that the aluminium plate provides stiffness and the white parts clamp the heatsinks with enough force that they stay in place. I don't know if a printed part will provide enough friction, but if it works it means that I no longer have to damage the surface of the copper with the grub screws. The potential problem is that it's likely going to be somewhat difficult to print on FFF. It should be possible though, but it's certainly a stress test.

The potential problem is that it's likely going to be somewhat difficult to print on FFF. It should be possible though, but it's certainly a stress test.Also note that I've designed it so that there's no front/back orientation. Over the course of this project, I've accidentally put the heatsink holder on backwards.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.