The outer cover setup and print

Surprisingly, this turned into a multi-hour ordeal. Some of that was just getting one of the uni 3D printers to stick to the bed, but it was mostly to do with setup.

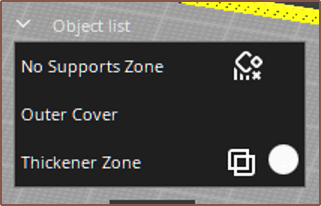

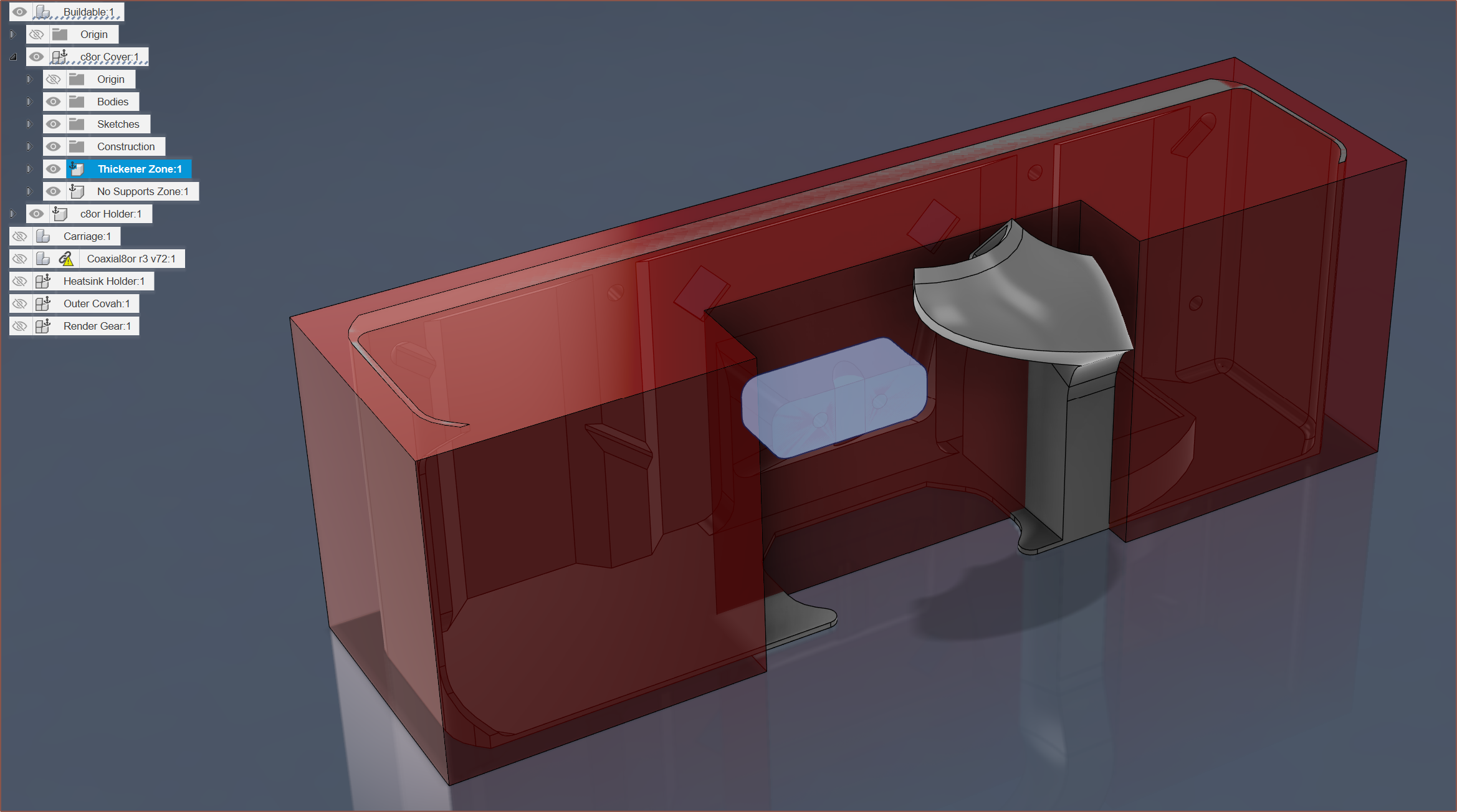

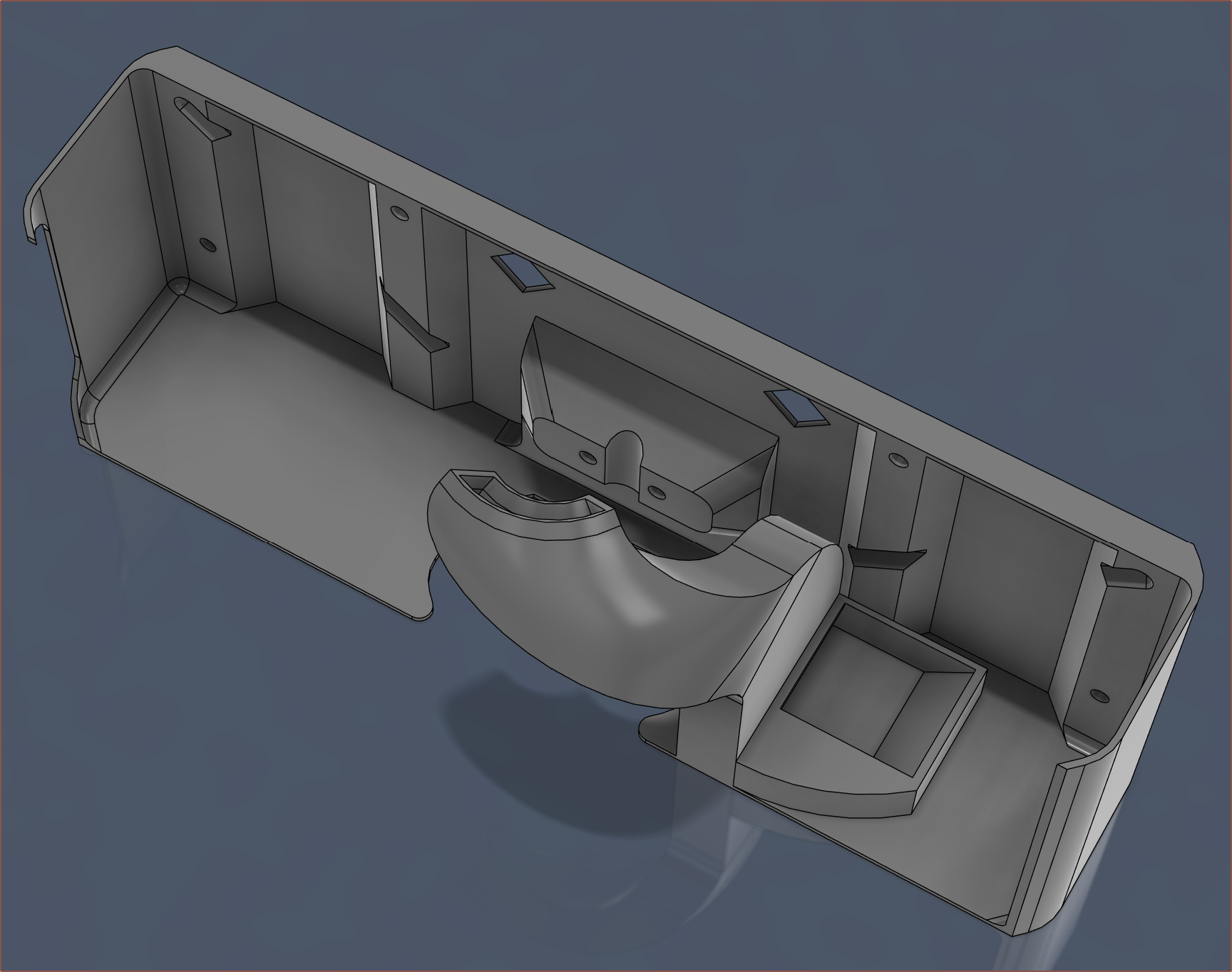

I don't usually design parts that need supports, so I had to be setting that up. But then I'd get supports where I didn't want them, and Cura really doesn't like reloading a multi-body .3mf, so I modelled the no-supports zone in fusion. Additionally, I added a thickened section. I should've just done 100% infill instead of the 40% I set.

I don't usually design parts that need supports, so I had to be setting that up. But then I'd get supports where I didn't want them, and Cura really doesn't like reloading a multi-body .3mf, so I modelled the no-supports zone in fusion. Additionally, I added a thickened section. I should've just done 100% infill instead of the 40% I set. Furthermore, as I was looking through the gcode preview, it did seem like there was a lot of excessive material being used so I trimmed it down. It also allowed me to catch an issue in the design, which is that I wouldn't be able to install one of the fans without first threading the wire through and resoldering.

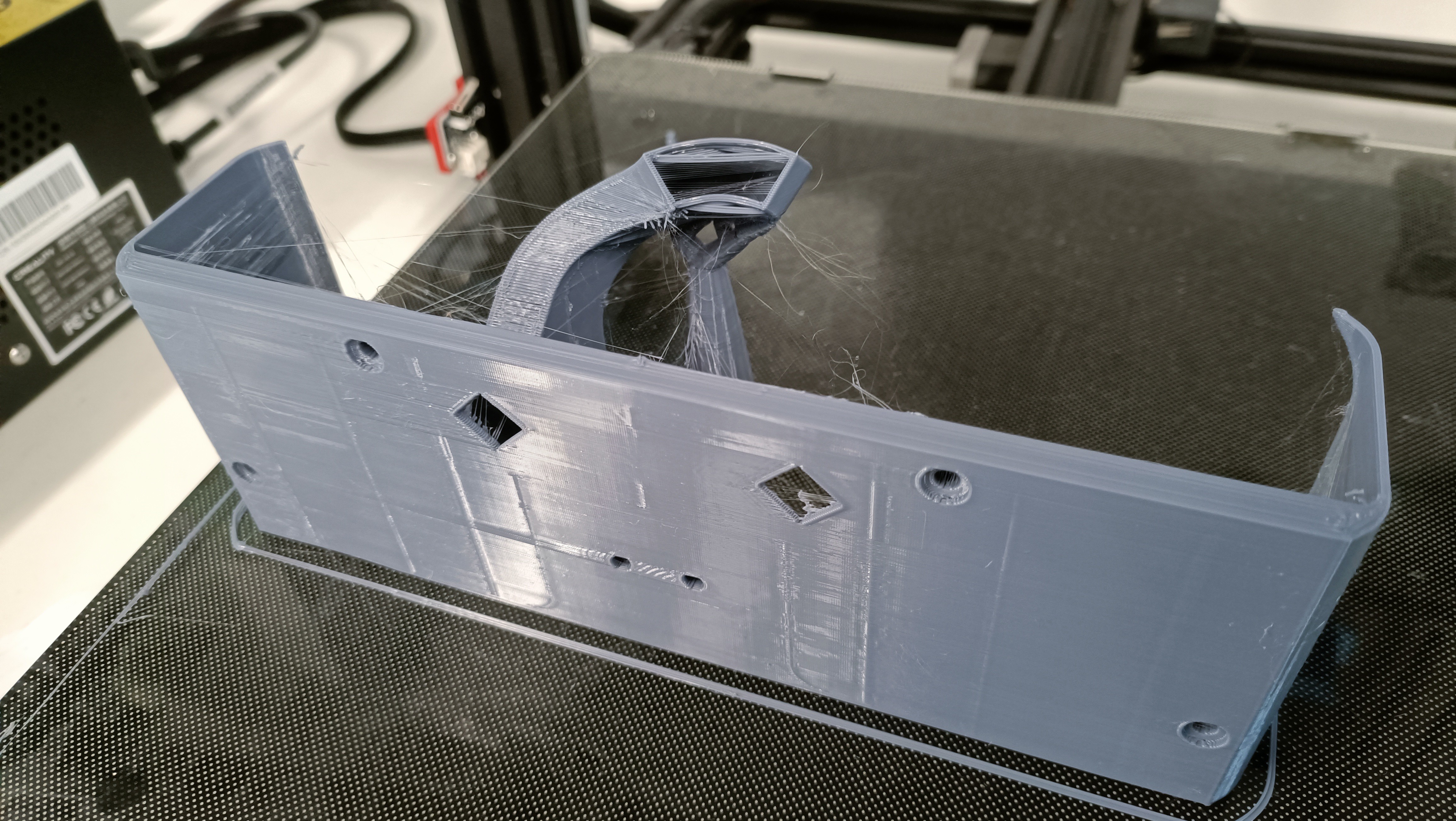

It has then been printed, and the tree support broke away easily.

It has then been printed, and the tree support broke away easily.

It does seem I overestimated how steep an angle I could print, which was 60 degrees. Instead, it seems that even 55 is slightly over the limit. I've changed a setting so that Cura prints from the inside outwards in aims of improving this.

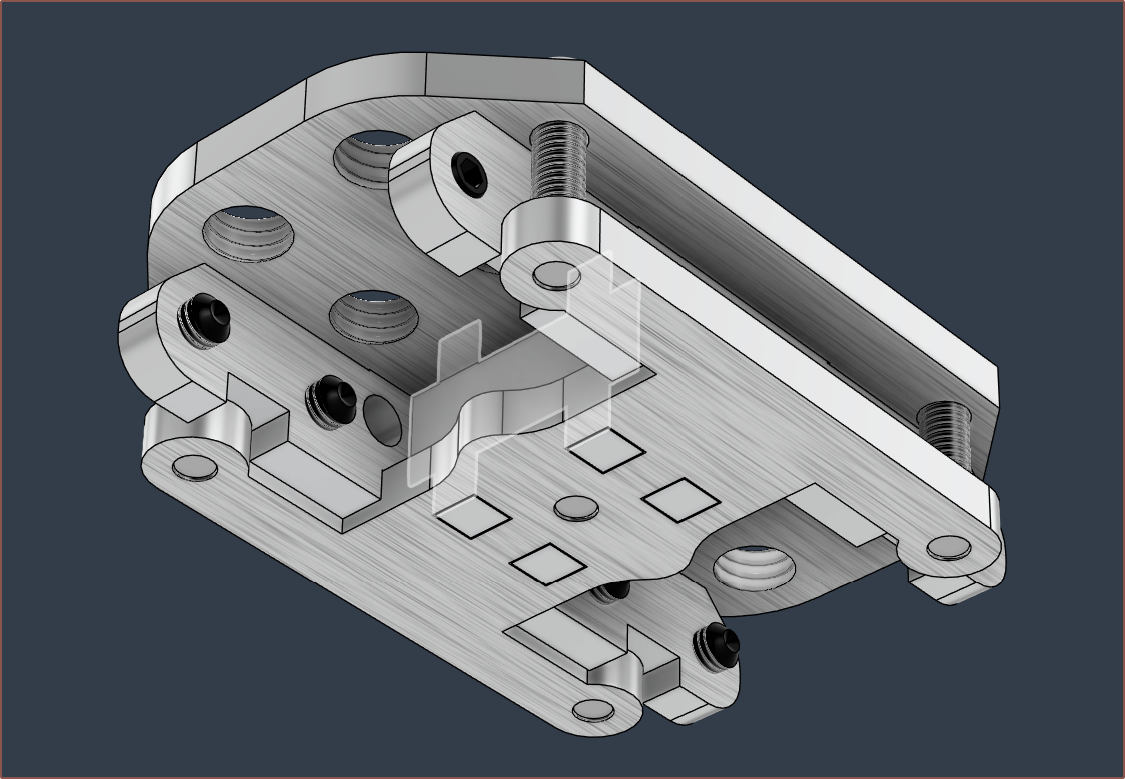

The hotend holder design

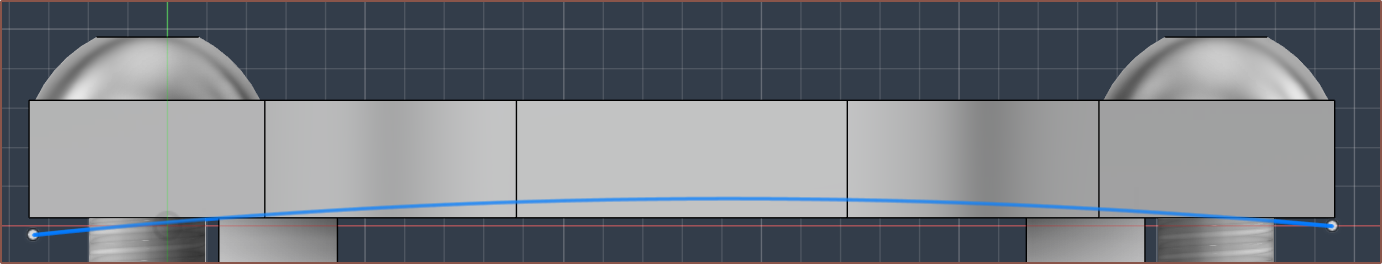

I thought through a mental simulation and, like I mentioned in the previous log, I didn't have the confidence that the way I designed the side plate a few days back was going to work as intended, due to material bending:

Thus, I've opted for a 5th M3x12 bolt and dual side plates:

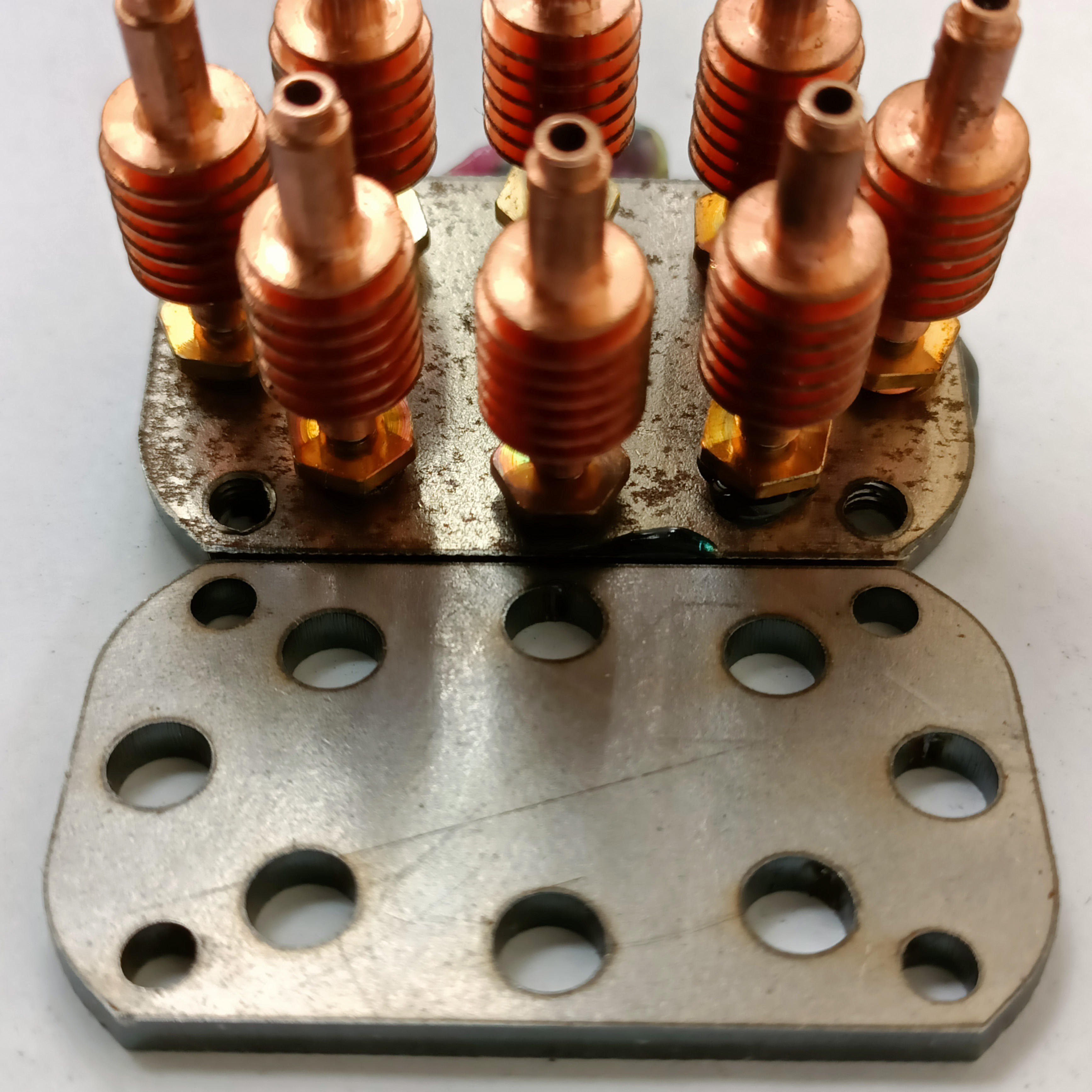

Clamp plate of R2

In anticipation of R3 and so that I can test the fit of the 6028 fans in the newly-printed cover, I disassembled R2. The reason why I haven't done much testing is that all the inputs were slightly leaking, as can be seen by the multicoloured blob that remained:

Like with last time, the strategy to separate and clear the heatsinks worked just fine:

Like with last time, the strategy to separate and clear the heatsinks worked just fine:- Unscrew the clamp bolts

- Heat to 150C

- Use spatula to separate

- Cool to 130C

- this prevents long, thin wisps and also allows for a "warm pull" of the inputs for the next step.

- Pull clamp plate from Coaxial8or

- Manually extrude material from each input till it pops out, after which the buldge can be snipped off and the filament recoiled.

- I did have to use needlenose pliers on 2 of the inputs to help them pop off the heatbreaks.

Thinking of reversing the extruders that have shorter bowden tubes

The DDEs, more commonly called "BMG Clones", should be able to work when mounted in reverse. The benefits include:

- Much easier access to the large gear, especially for extruder E6

- (remember it's E0 - E7)

- The short bowdens will be even shorter

- The drive gears are closer to the handle end of the DDE.

- The improvement would be about 50mm or so, which will contribute a larger percentage difference for the 30-35cm bowdens of E0, E1, E6, E7 than the 45 -50cm of the others.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.