[May 5, 15:20]

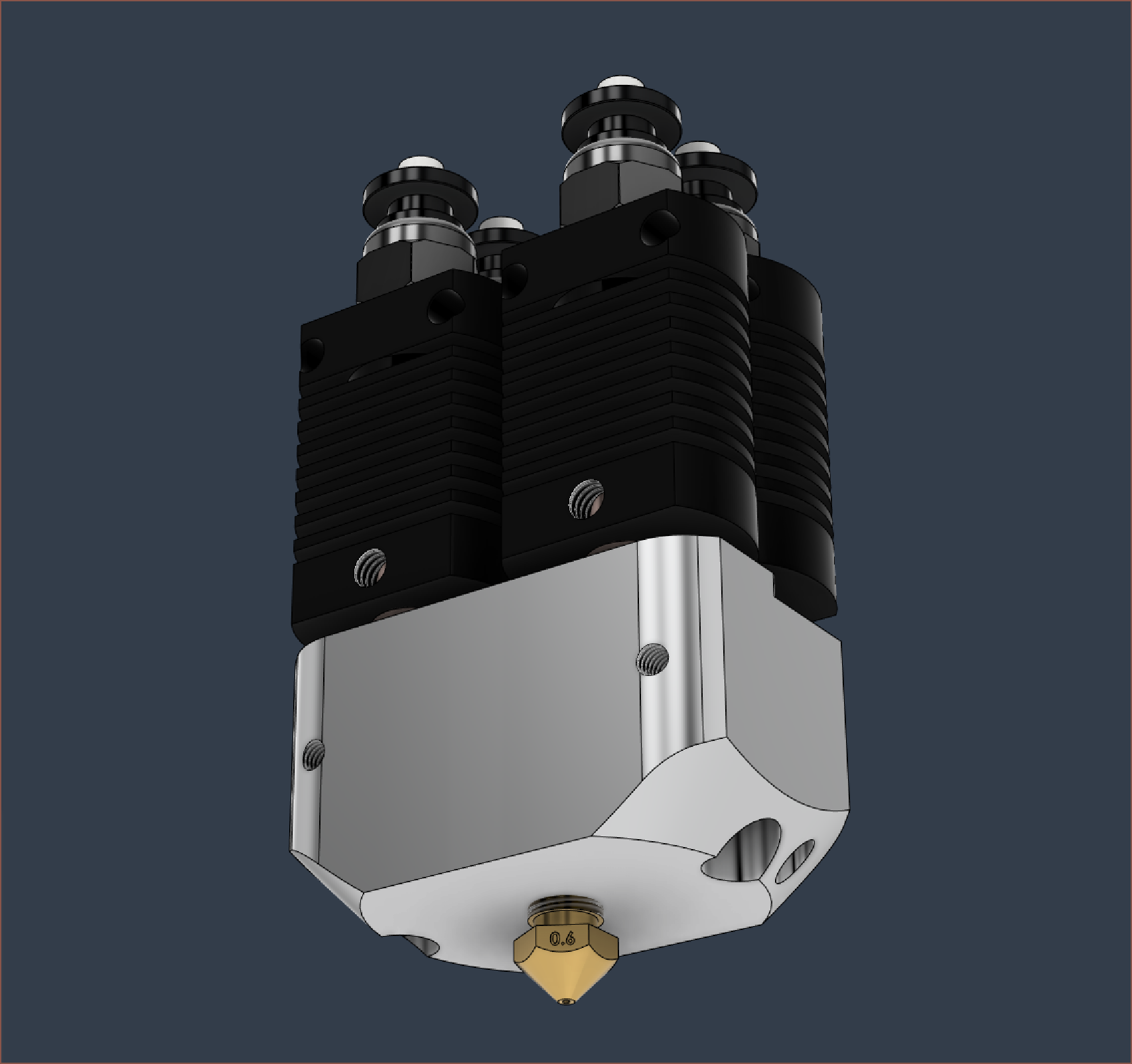

So I was still thinking about how nozzleboss got thier solution printed for 37$ whilst my traditional manufacturing solution is 70$ with another £10 ($12.50) in off-the-shelf parts for the internal geometry. Like all the "I just got access to a metal 3D printer" engineers before me, I wanted to see what complexity reduction a 3D print editon would be.

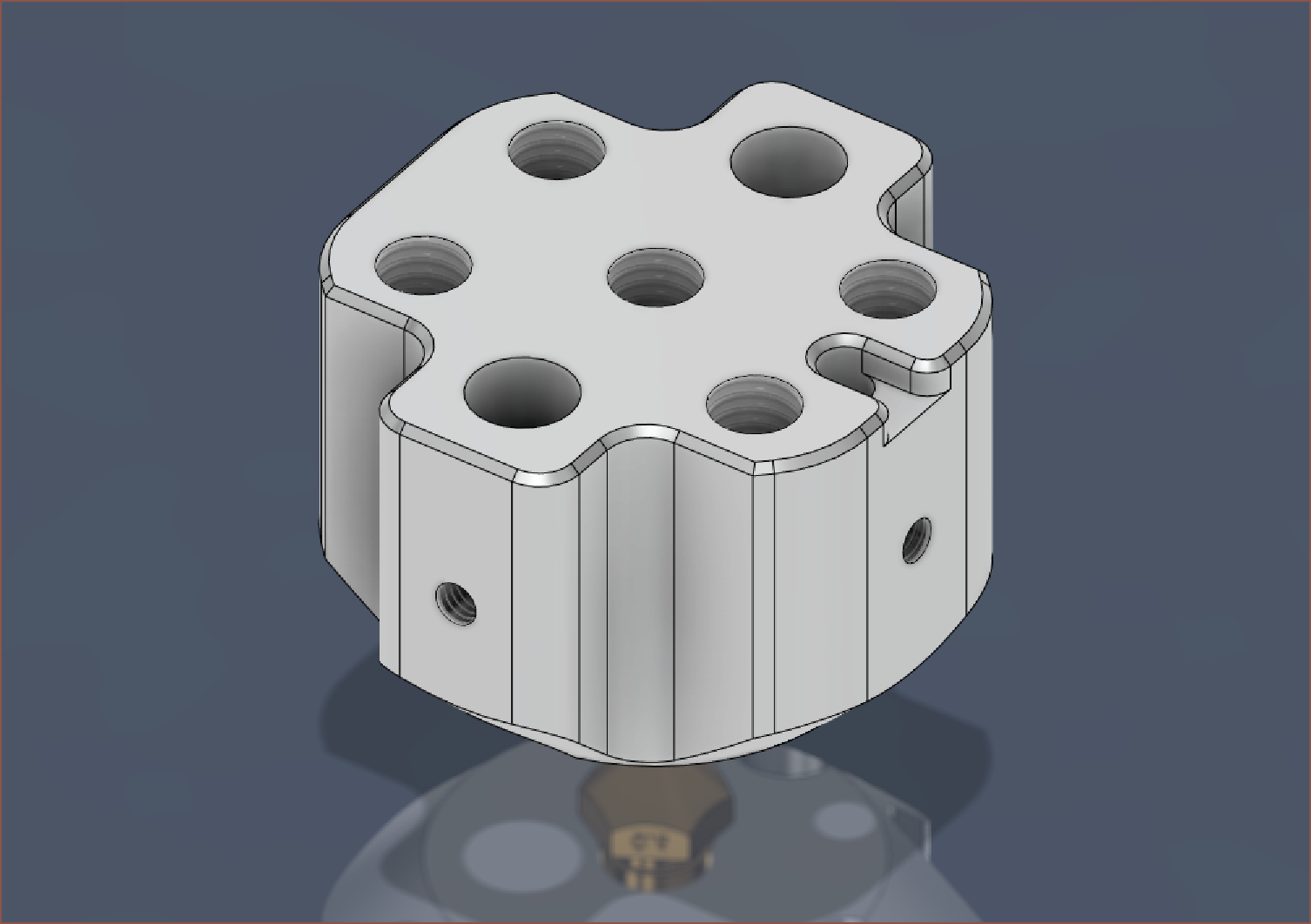

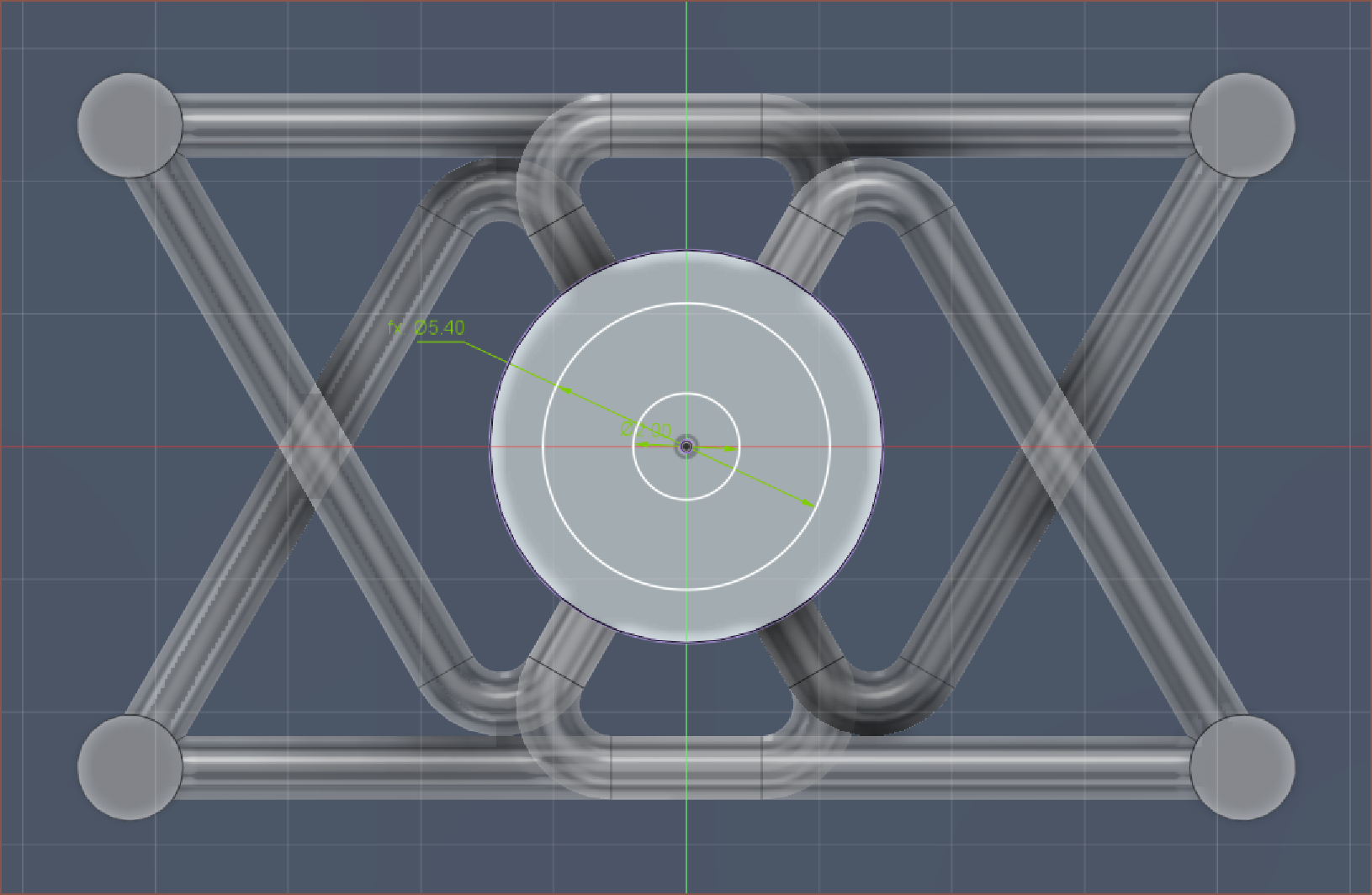

Firstly, I sent over the latest Lathe Edition file to PCBWay:

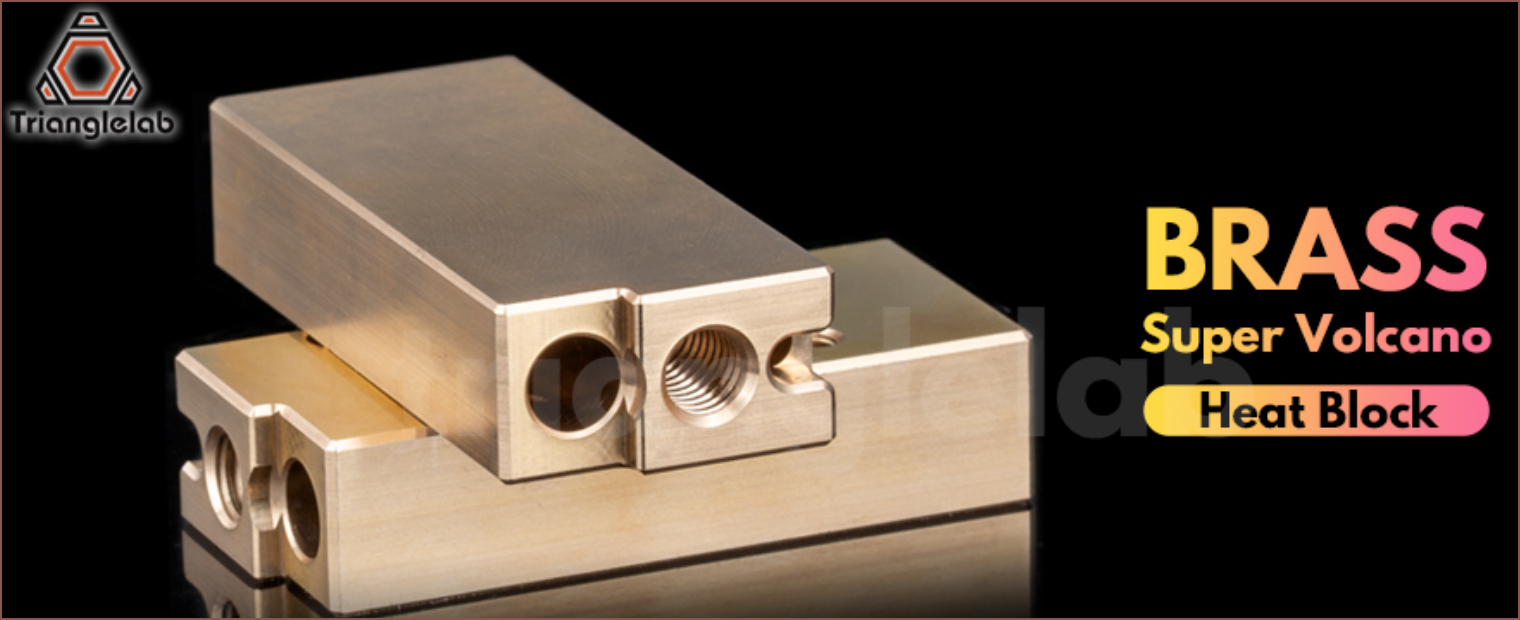

It's an expensive part, so I thought I'd at least add the finishing features found on my brass supervolcano, such as the 0.5mm chamfer on otherwise sharp edges and the fillet around the thermistor wire cutout:

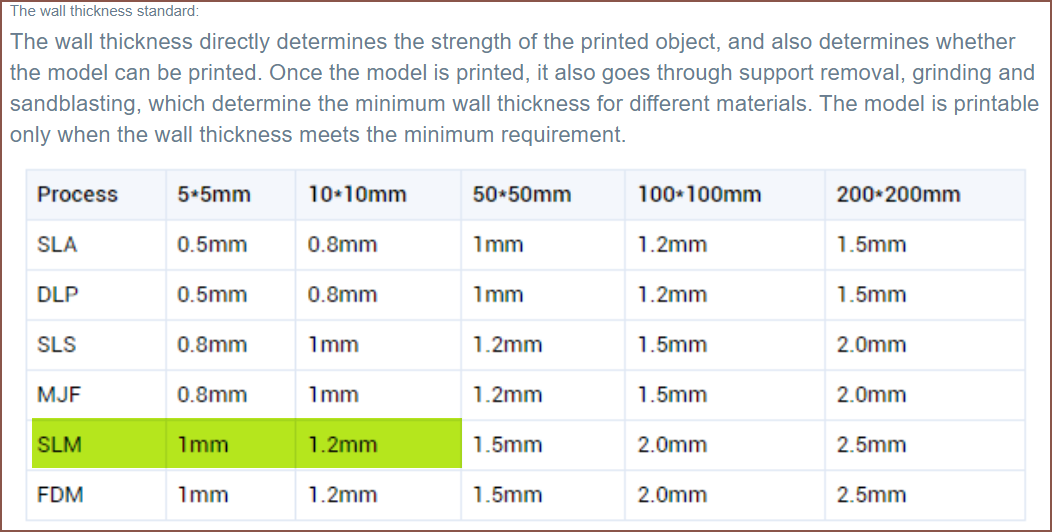

Then I did a Save As and started doing the tweaks I needed to do. Looking at PCBWay's minimum wall thickness table, I went with making sure walls were over 1.2mm thick.

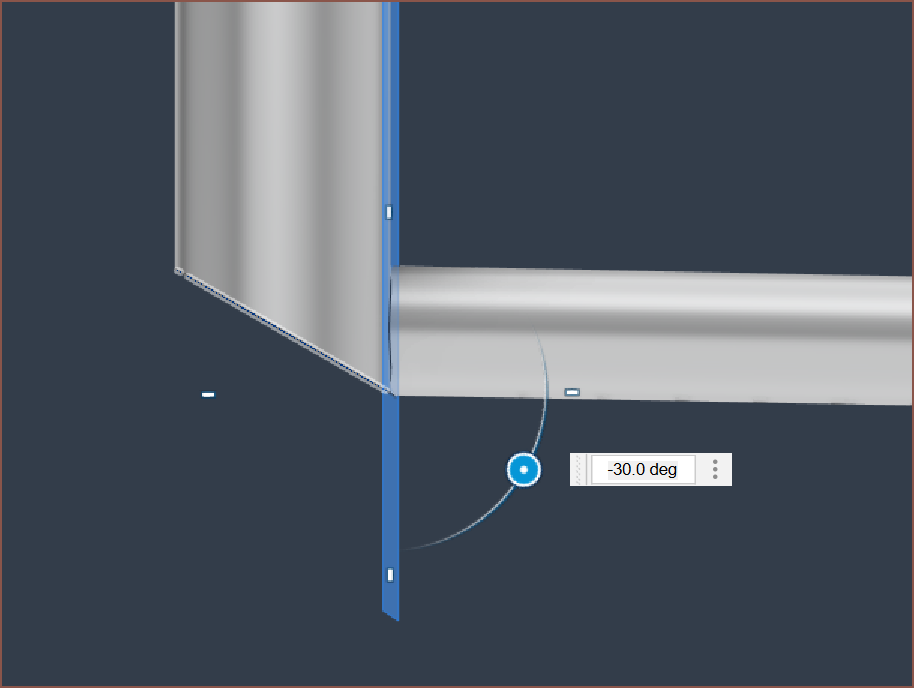

I can even add an angle to help the flow:

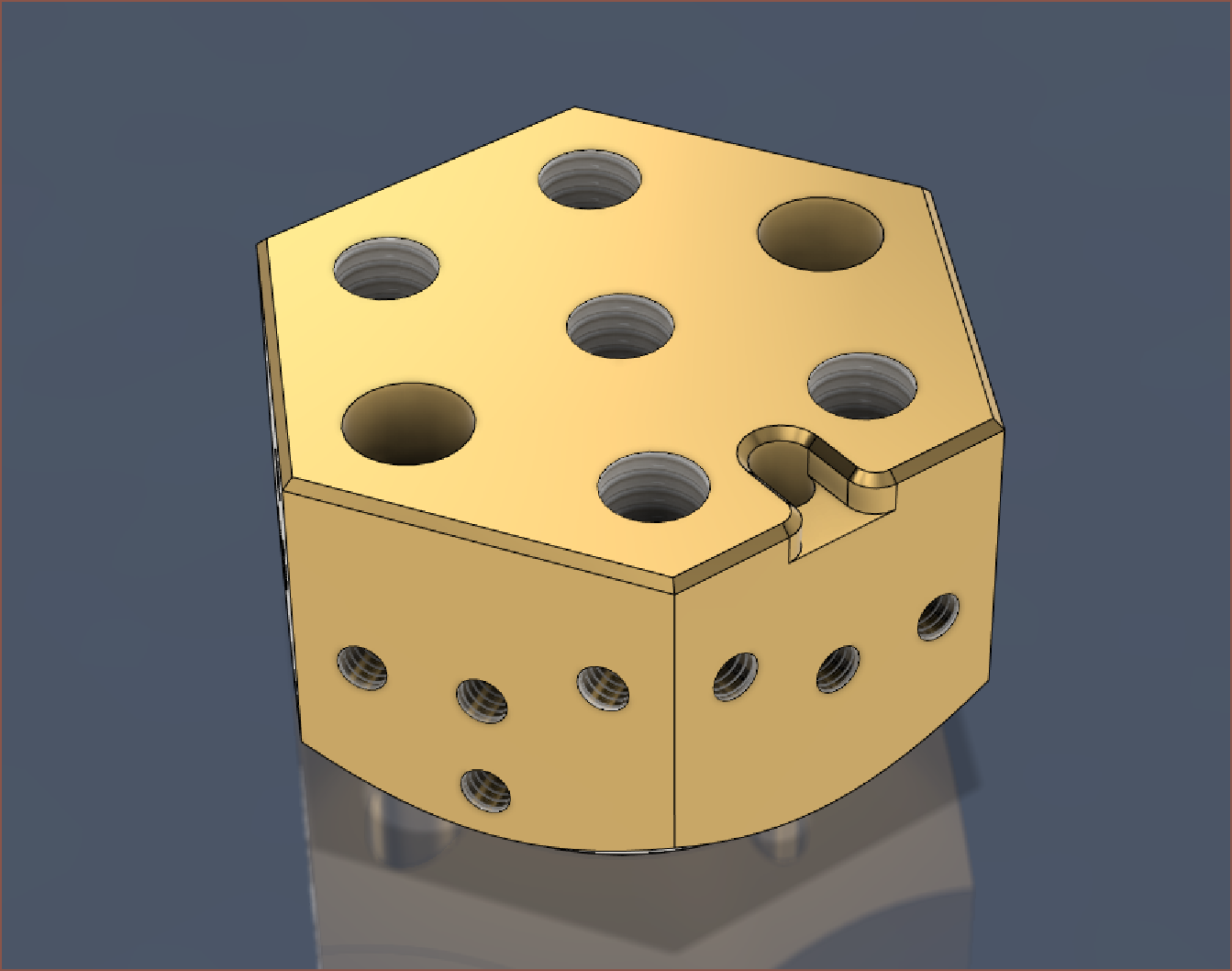

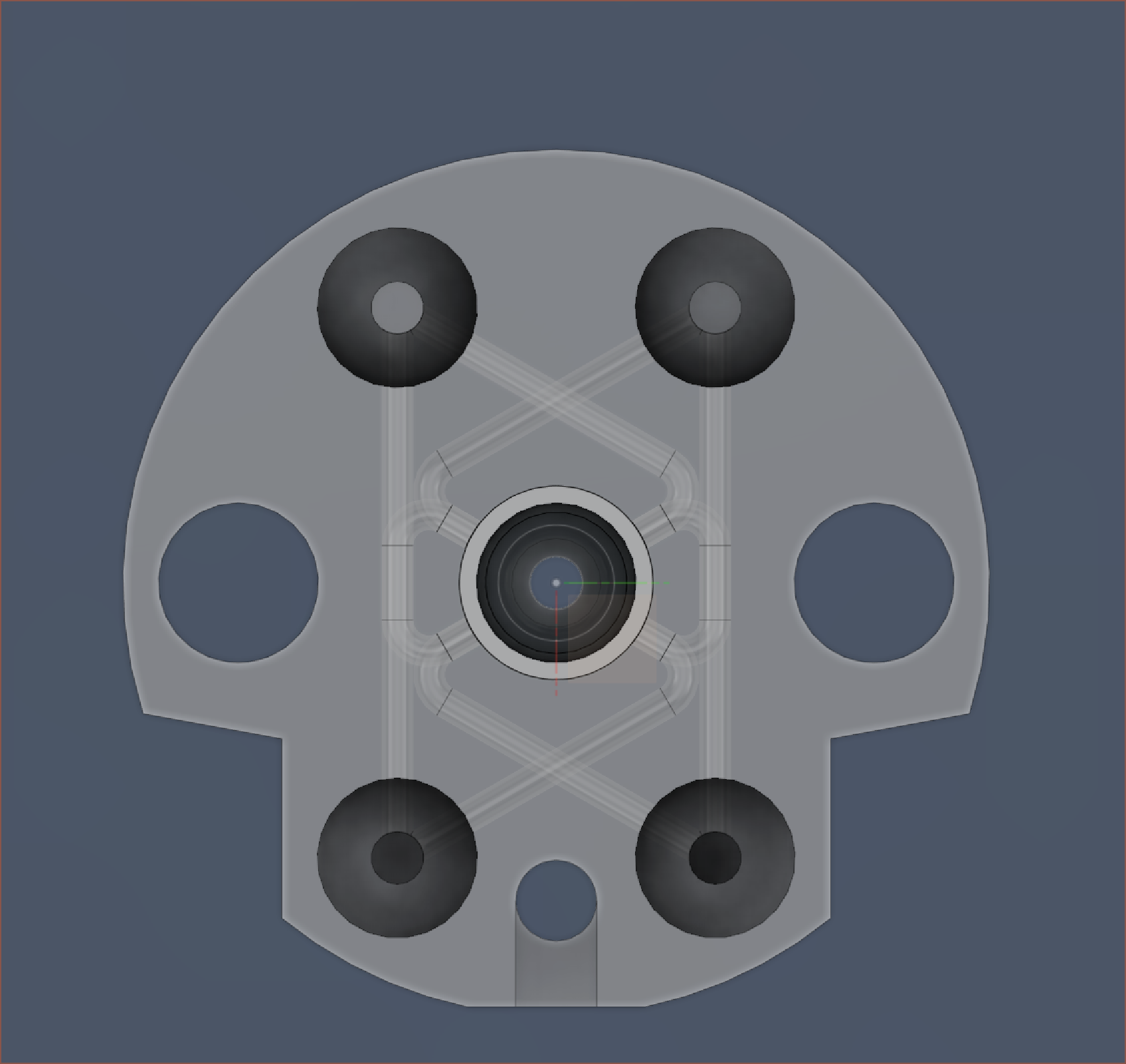

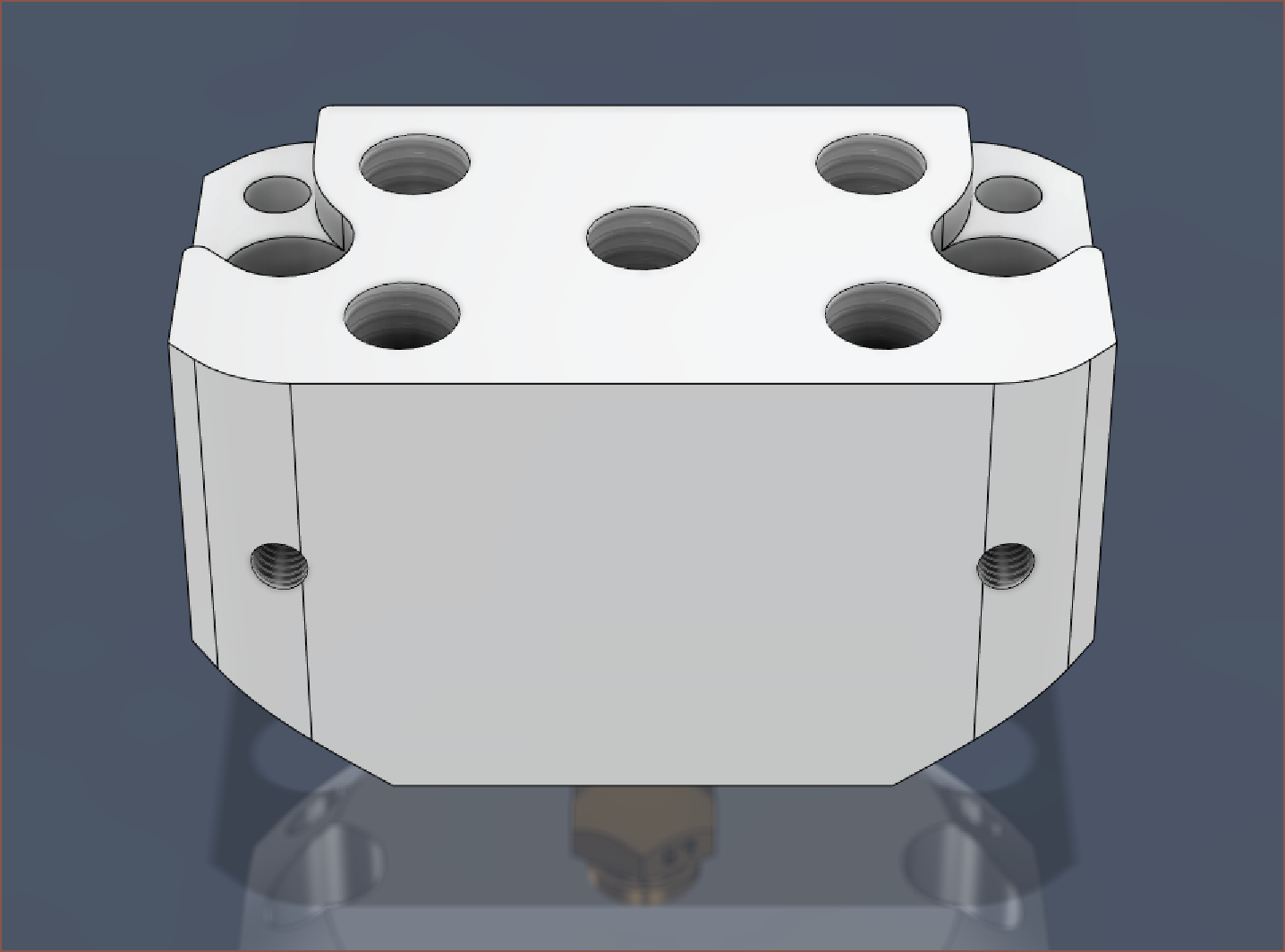

This is the point I got to when I realised that I didn't have to conform to a circle or hexagon but could have whatever shape conformed to where I needed it (so obviously I got a filleted chamfer in here).

This allows for a 5-in-1-out solution without additional manufacturing complexities.

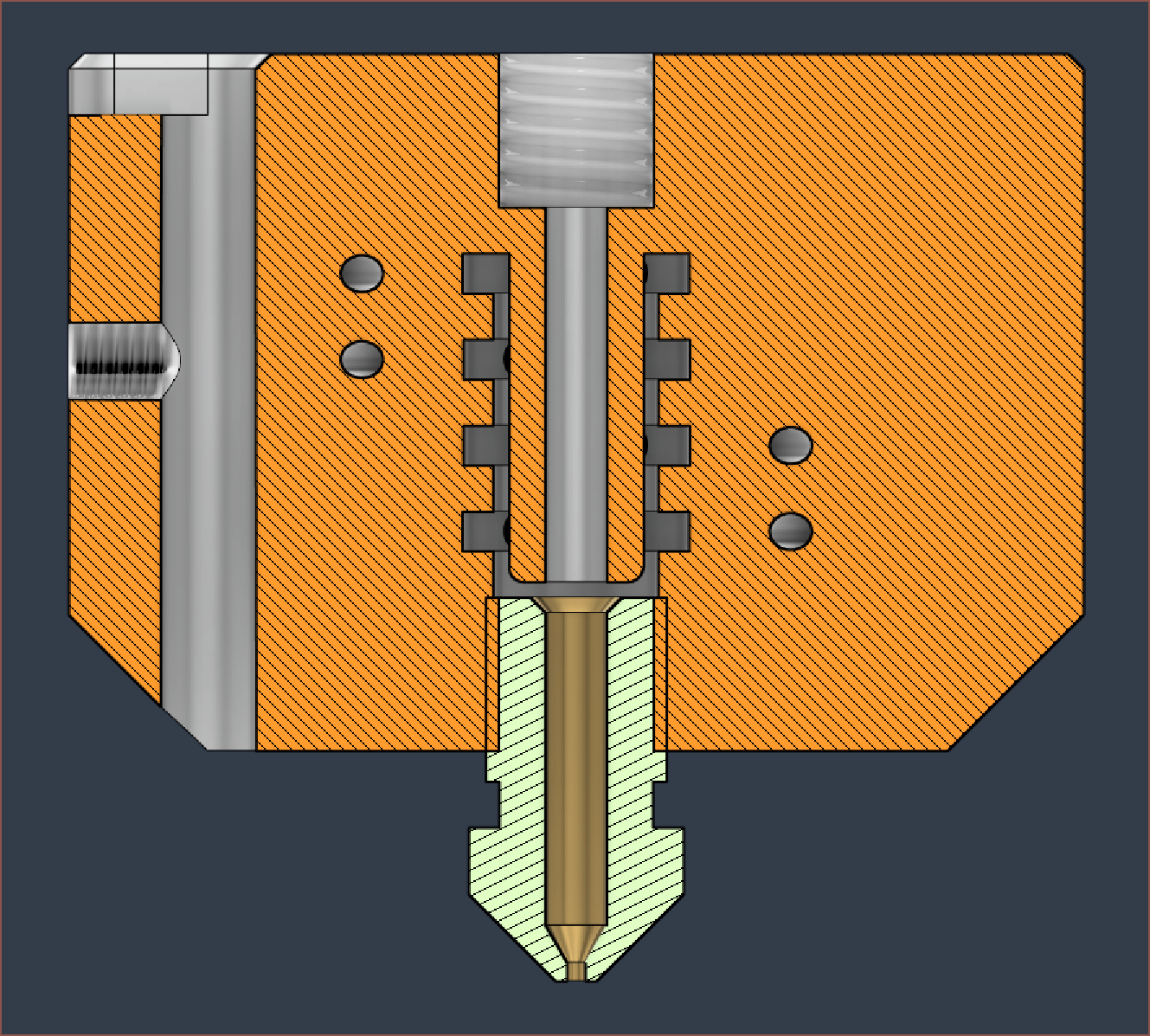

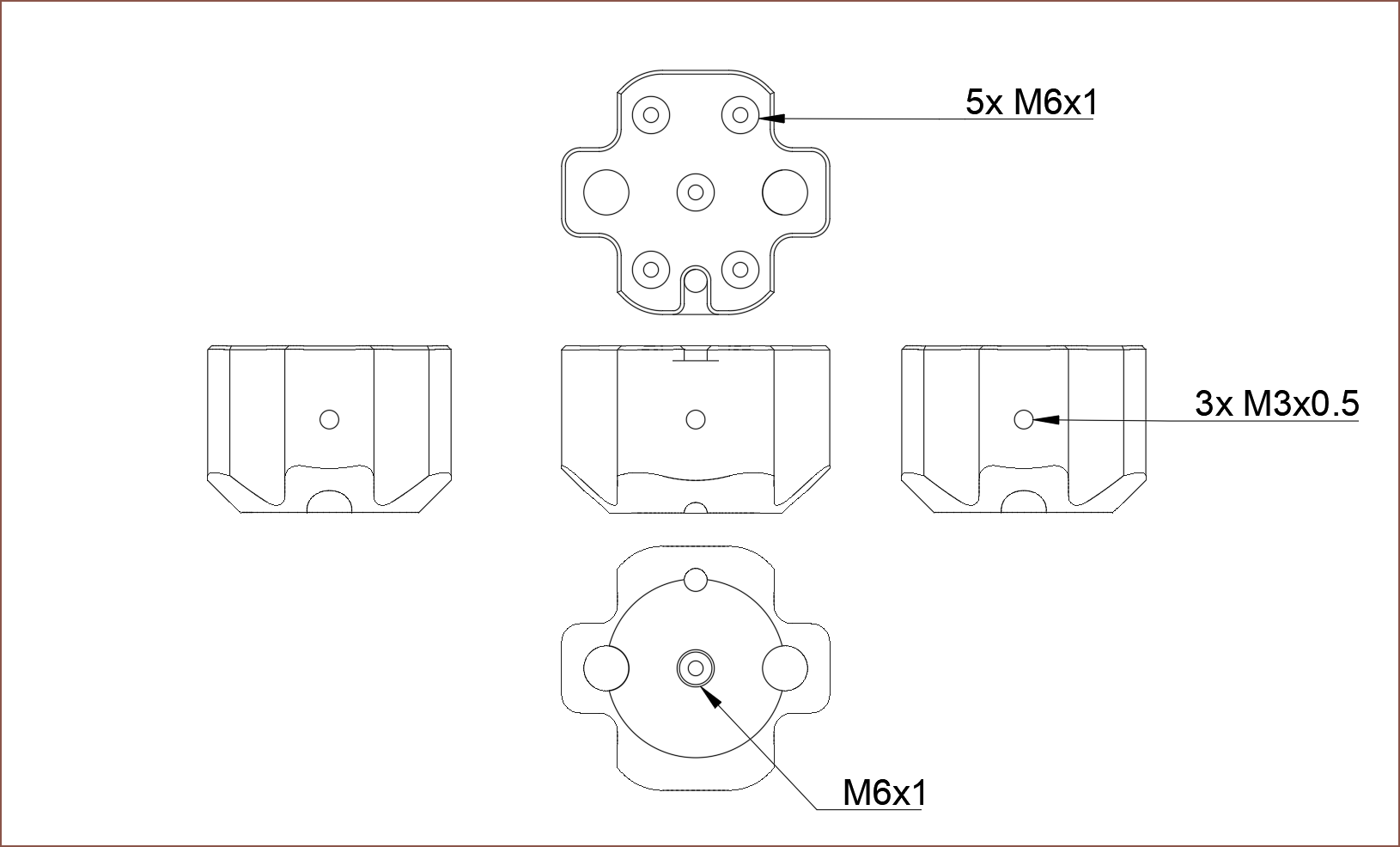

I like how easy it was to go from lathe -> 3d print design. I'd imagine it'll be an uphill effort going the other way around. The technical drawing is also simplified to just pointing to threads:

The PCBWay autoquoter says $46 for aluminium, which is 75% of my first 3d print autoquote. Hopefully, since this doesn't have as many tapped threads as the first design I had, it actually stays close to this and doesn't double in cost. Additionally, the time spent searching AliExpress for components could've been reduced too, so I can see the benefits of 3D printing.

Because it's aluminium, the mass is a rather light 42g. Sounds like a significant weight saving, but the lathe edition is 45g when cut from aluminium.

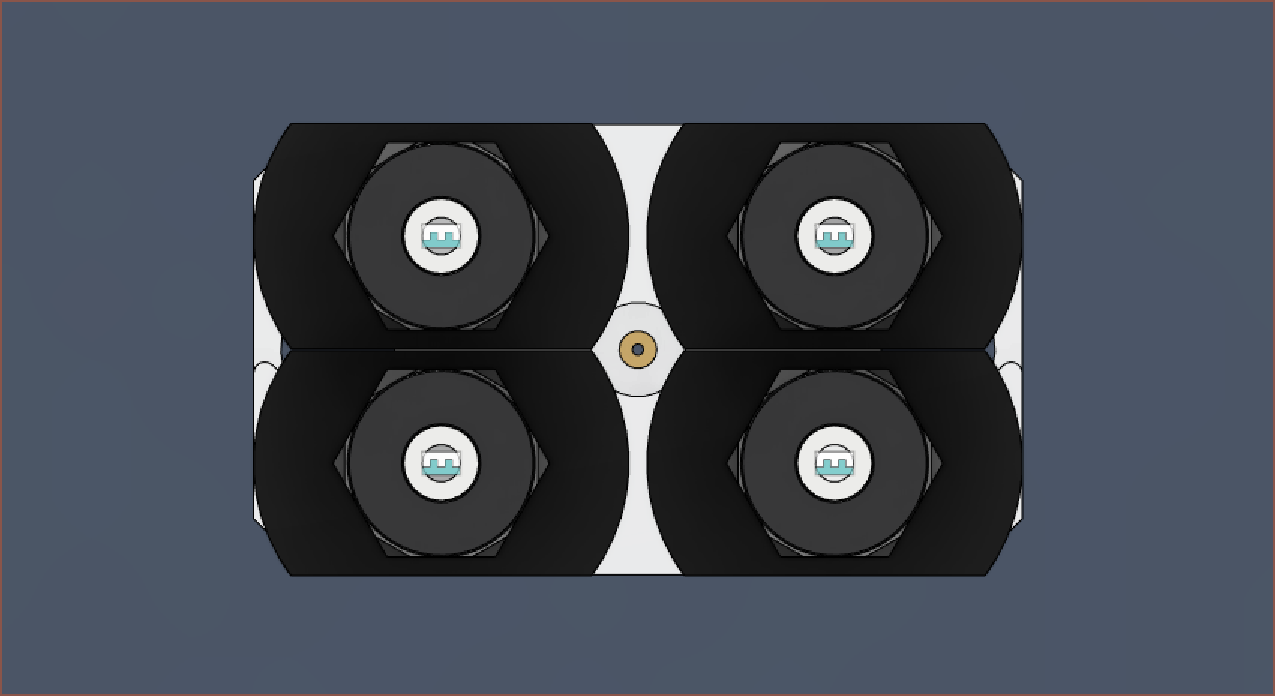

[16:20] Looking at the block, and the fact that the heatsinks extend a bit over the edge, I thought I could actually turn the + looking shape into a smooth rectangle, and it was a success:

In terms of mass... it's 45g. In terms of heat conductivity... the cartridges are further away from where all the molten plastic is. In terms of price... it's more expensive:

So it's like an all round net negative. Might as well make the thickness 24mm so that the thermistor has more thread length and the block flush with the heatsinks:

At least it looks nice and compact:

And I guess with this design, you can actually have dual thermistors since they're so close to the heatsource.

[May 6, 08:40] The quoted price for the non-slim edition is $72.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.