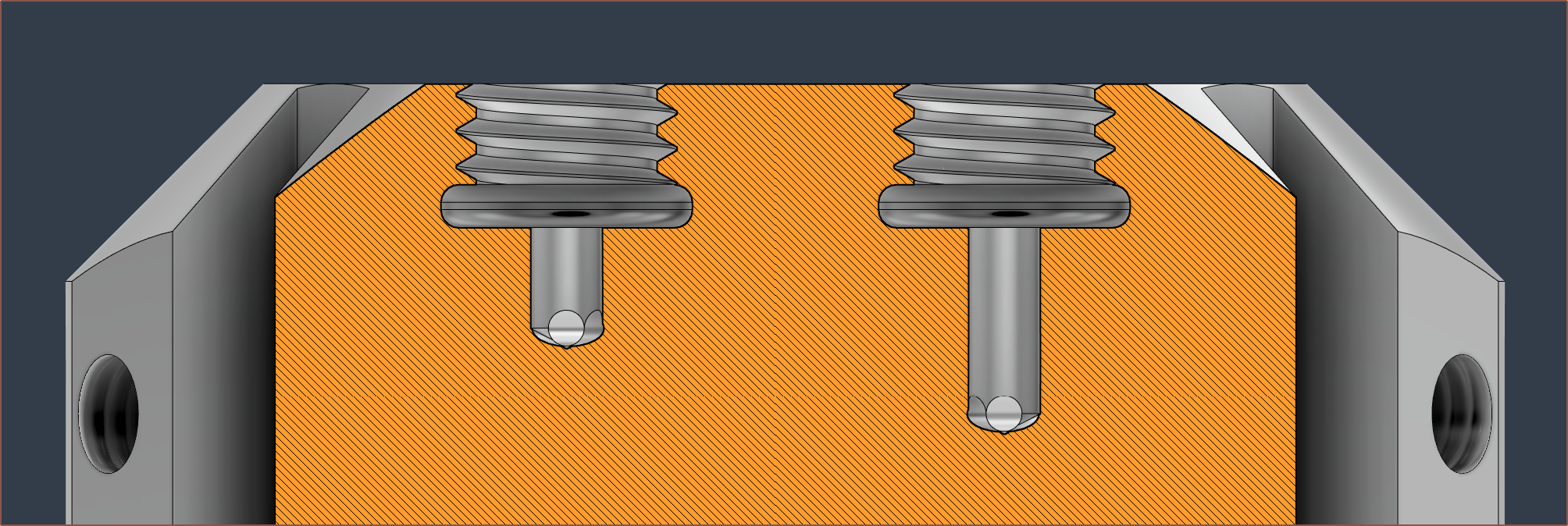

I have a diamond hotend I never got around to using and I looked at the M6 thread inserts to see what was done for that heatblock, and it looks like the bottom-most threads a missing. It actually looks like there's a very slight undercut. This is likely due to the inability to perfectly tap all the way to the bottom of the blind hole. I'm hypothesising that this is the reason why I got leaks.

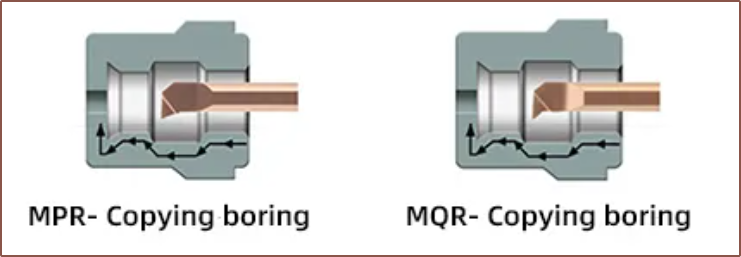

To counteract this, I've added more internal groove cuts to the bottom of the threads. It's rounded because it uses the same tool as the coating grooves, though something like an MPR or MQR looks to be more of a match for this.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.