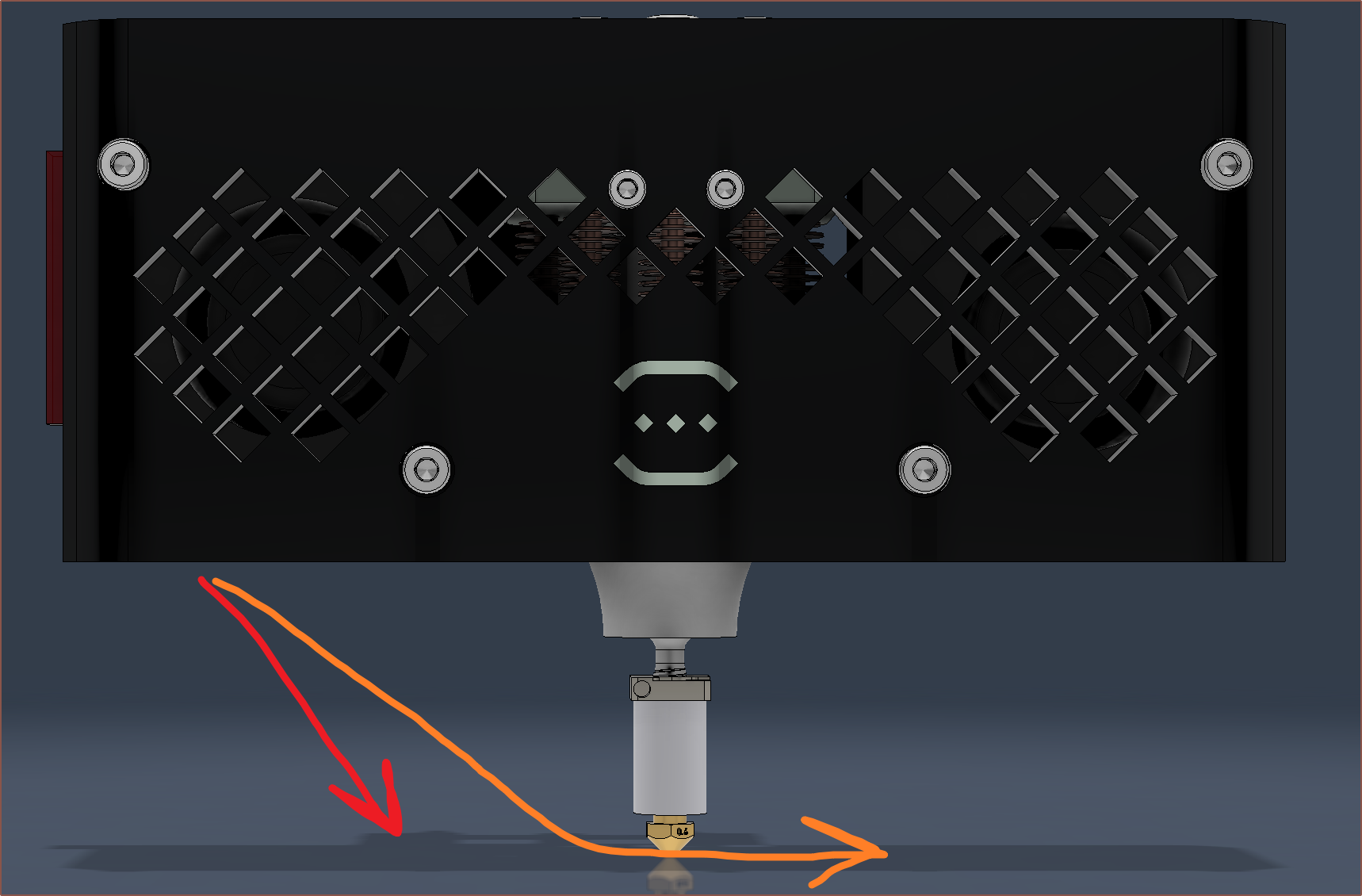

Part cooling

I'm hoping that I can actually just further direct the fan air so that I can have an open, ductless hotend. The red arrow is the expected current air direction (from feeling the output air stream) and the orange is the ideal air flow with a duct similar to a tower fan or car AC.

Filament Strategy

The Aesthetic Series

I've also considered a new solution of filaments and their order:

- White

- Also used for cleaning/purging since it's readily available and white PETG/PLA/ABS is less flexible than cleaning filament thus easier to extrude.

- Silver / Stone

- Silver: A bright silver material for creating silky or metallic-looking materials like copper, gold or car paint.

- Stone: A white, mortar-looking material for creating rocky materials like brick, sandstone or concrete. This may need the fuzzy-skin slicer feature to make it really look like stone.

- Black

- Moved to before the CMY colours so that it effects subsequent colours less during changes.

- Yellow

- Magenta

- Cyan

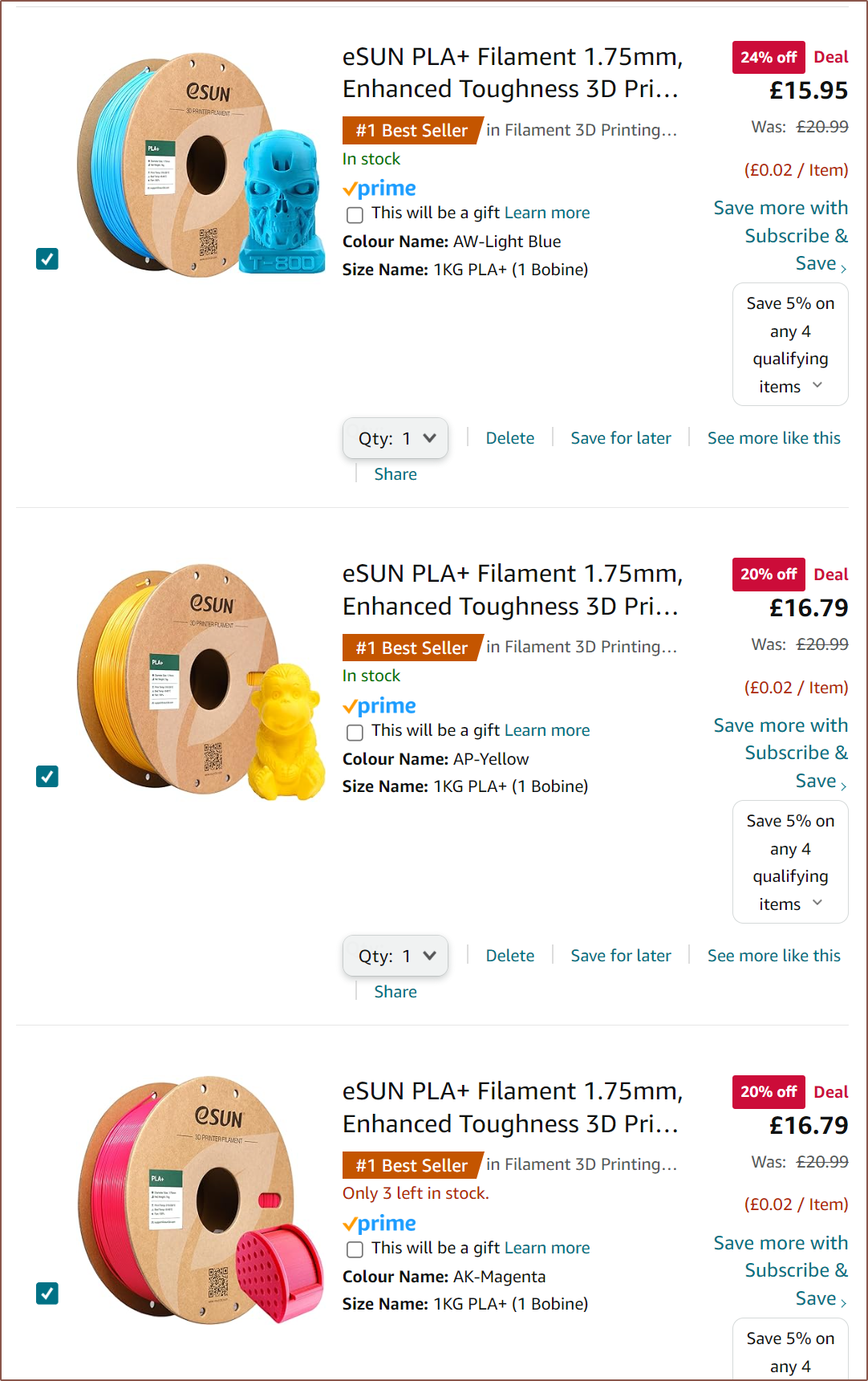

- Potential CMY filaments from eSun:

- Transparent

- This is also so matte or glossy materials can be created. If the other materials are glossy, this would ideally make the final filament look matte.

- [Edit 1 - Feb 22] However, for an alpha channel, this will have to be the first material input into the system.

- I have higher expectations that this would work compared to the gloss/transparency strategy.

- TPU Glue

- Ideally, this is a material that usually won't stick to the previous materials so that its absence can act as a support interface.

- May conflict with the glossy/matte strategy (if it's even possible), which is probably fine because any print that needs that feature is likely to be more aesthetic in nature anyway. It is a better strategy to load in both silver and stone.

Other materials not considered in the above strategy:

- Wood - would go between Silver and Black so that different grains could be printed

- Marble - between Silver and Black, or replaces Stone

- Glow-In-The-Dark - between Cyan and Transparent

- both as only the surface will emit light and so that the transparent material can both protect the nozzle and make ghostly filament.

- CF-PETG/CF-PLA - replaces Black but would likely be in the "engineering series"

- Soluble - replaces TPU Glue

- Rainbow - it'll be a disappointment if such a filament is needed on a hotend like this

- Toothpaste

- probably depends on the print and the colours, but I don't even know if the toothpaste effect would even be preserved

- Foam - Like CF filaments, it's probably something for the "engineering series"

The Engineering Series

It's understandable that an engineer won't spend £300 to mod their printer just so that they don't need a massive filament rack (likely also valued at £300+). This is why I've also thought of the engineering series strategy, which is properties based:

- The cheap all-rounder (PLA/PETG/ASA)

- The high temp (PBT/PC/PPS?)

- placed after the cheap all-rounder so that there is a chance of purging it out

- The (very) flexible

- So that the flexible-to-rigid range is as wide as possible.

- Conductive

- Chopped fibre / stiff

- Most of the stiff material should be formed in a tube-like extrusion as that's where most of the stress will be concentrated.

- High inter-layer bonding, low stiffness and UV resistant.

- AKA TPU Glue

- Foam / expanding

- Ideally, this would actually go before most of the other materials to emulate AMTEx, but I don't think reality will be so idealistic.

- Soluble

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.