On the 14th Feb, I was looking to send off my most recent design for a quotation and I noticed that it was mostly unchanged since the 3rd and believed that I could optimise some things.

Optimising some things

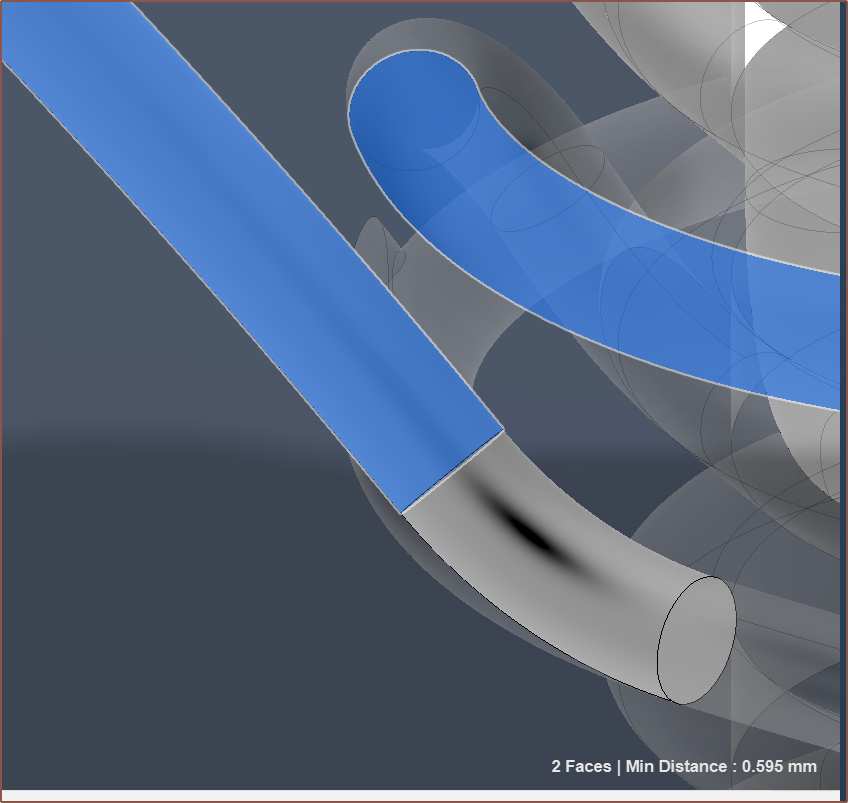

It didn't take me long at all to find this minimum wall violation:

So I tweaked it so that, in theory, less material would be needed for the hotend and the filament path would be shorter:

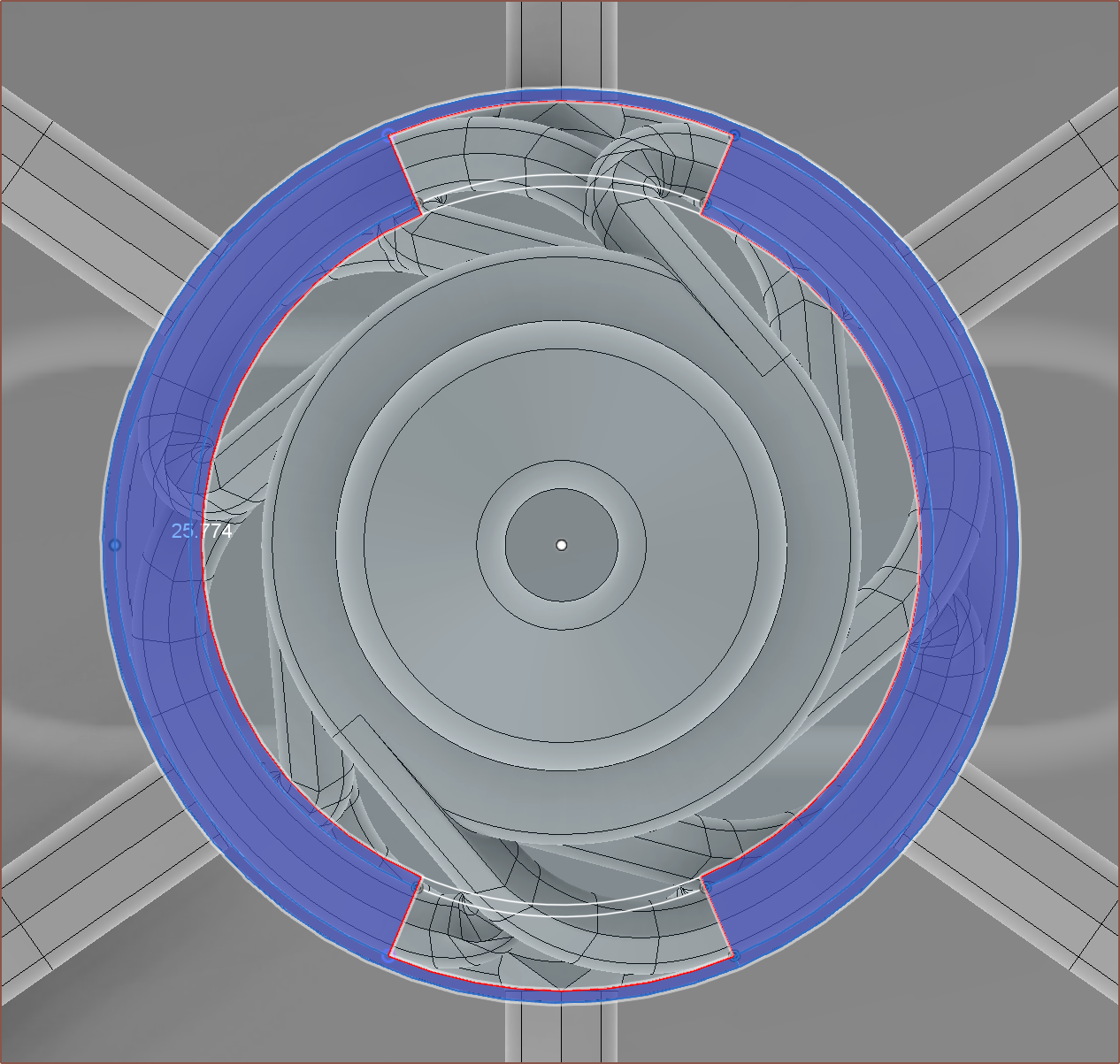

Then there was a violation inside the actual "coaxialiser":

So I fixed that as well as the minwall violations for the heater cartridges:

I got a preliminary price of about $53 and mentioned the internal channels in the notes just to make sure the engineers were aware of them. I had only dropped maybe 6g so those are some expensive grams.

Me: I've gone through and optimised the design. If it was OK before, it should be smooth sailing now and with a lower price too!

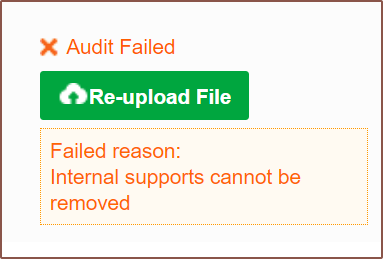

PCBWay: I've got issues with all of this, this 'n' this.

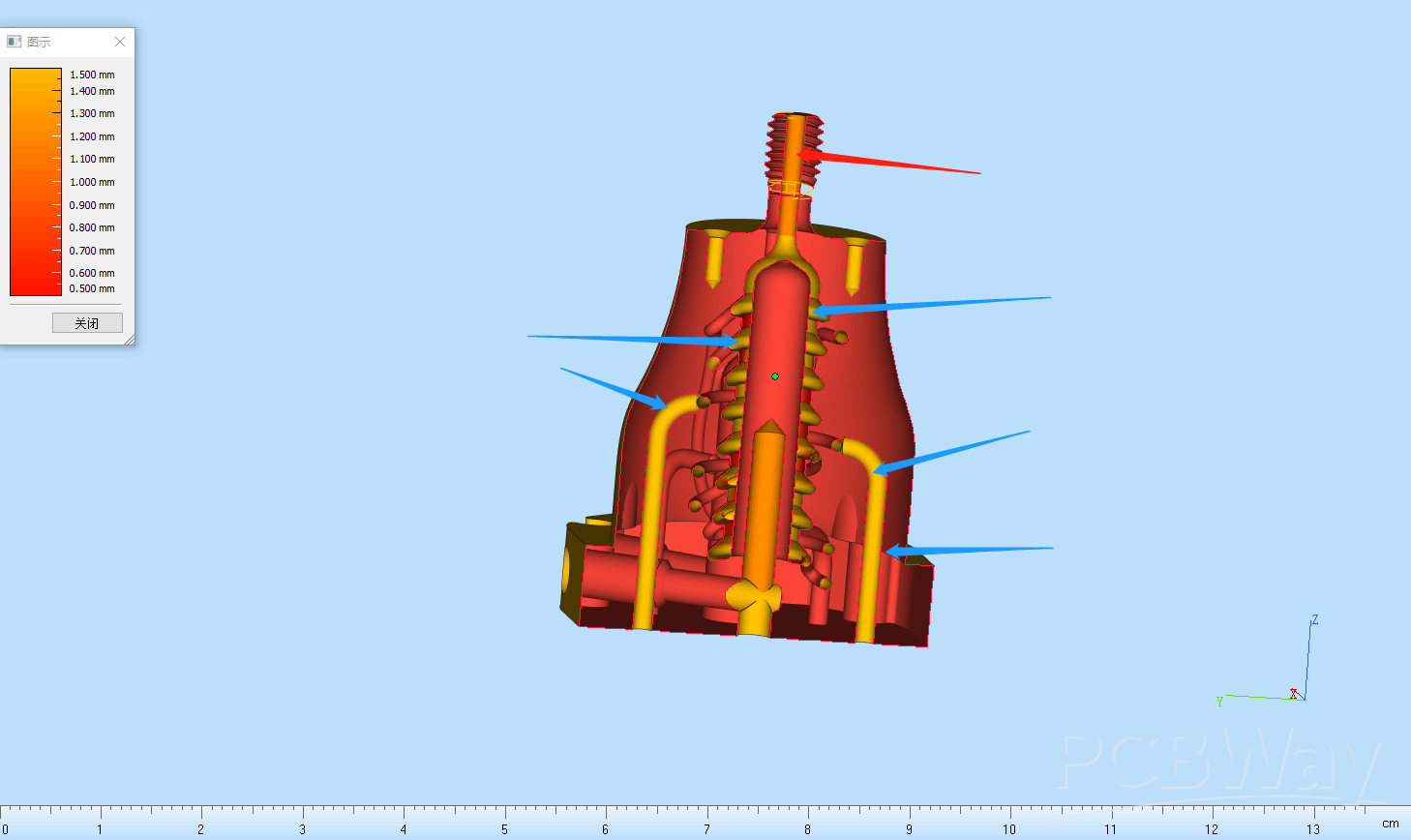

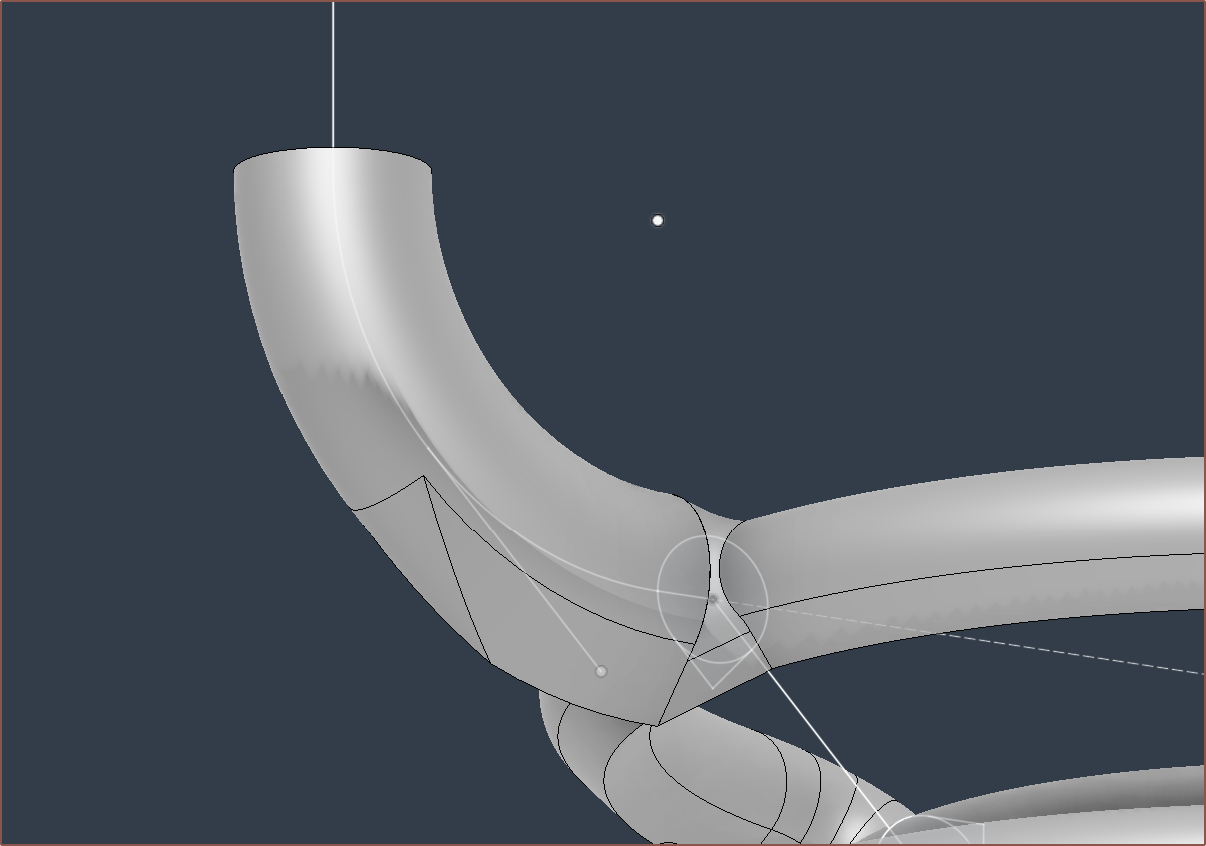

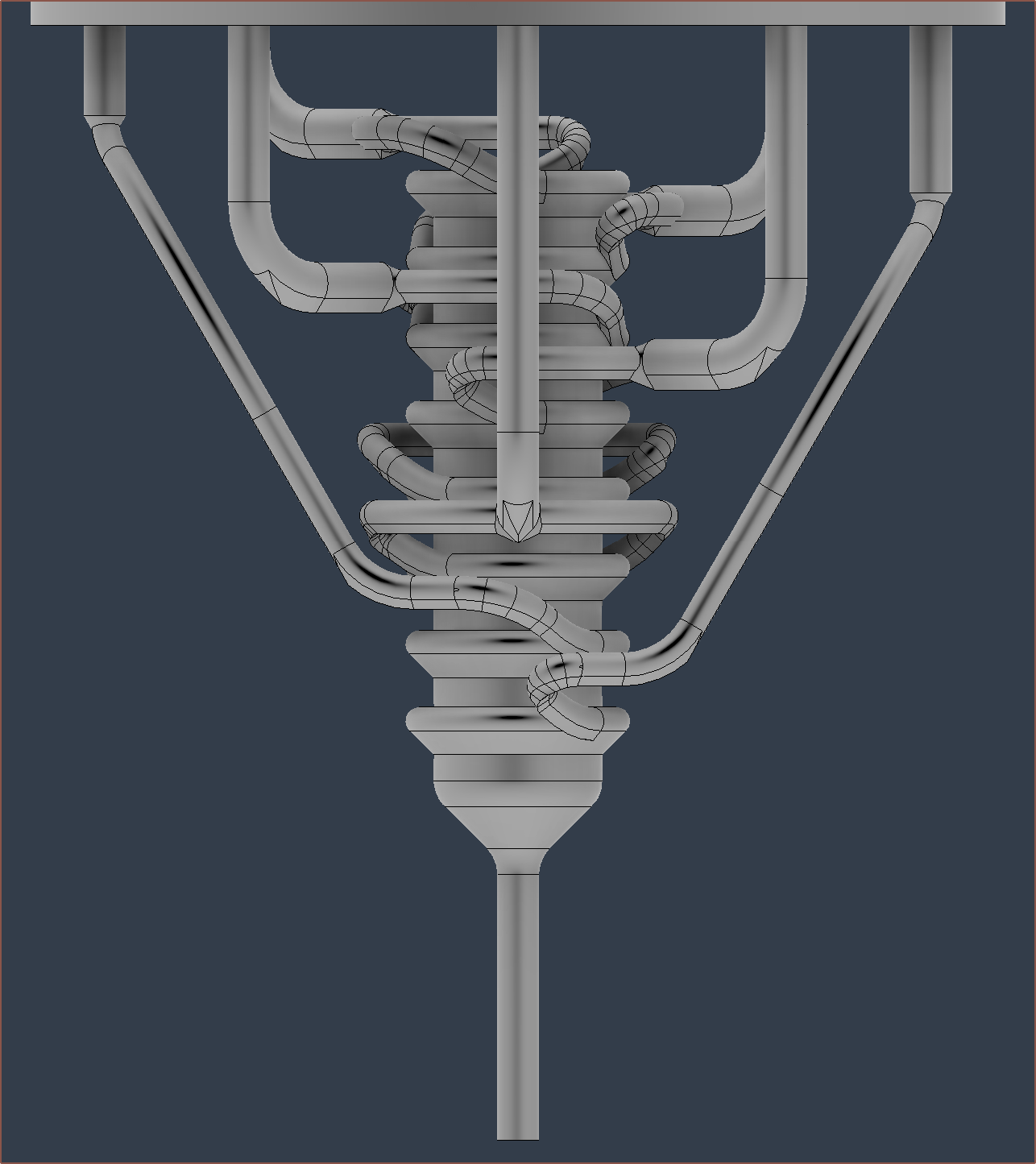

This is what I found on the 16th (2 days ago) and I expected that I actually had to model in the raindrop-shaped overhangs throughout the design. Today, I woke up and attempted it, but first told Eleven (my PCBWay agent) my plan. Partway through, she said that wouldn't do anything as there'd still be internal supports. Confused, I asked to see what supports are actually being generated and I got this:

Assuming that they thought I meant "why not just rotate the part 45 degrees" instead of "I will replace the overhangs with 45 degree faces", I continued.

Modelling 45 degree overhang eliminators

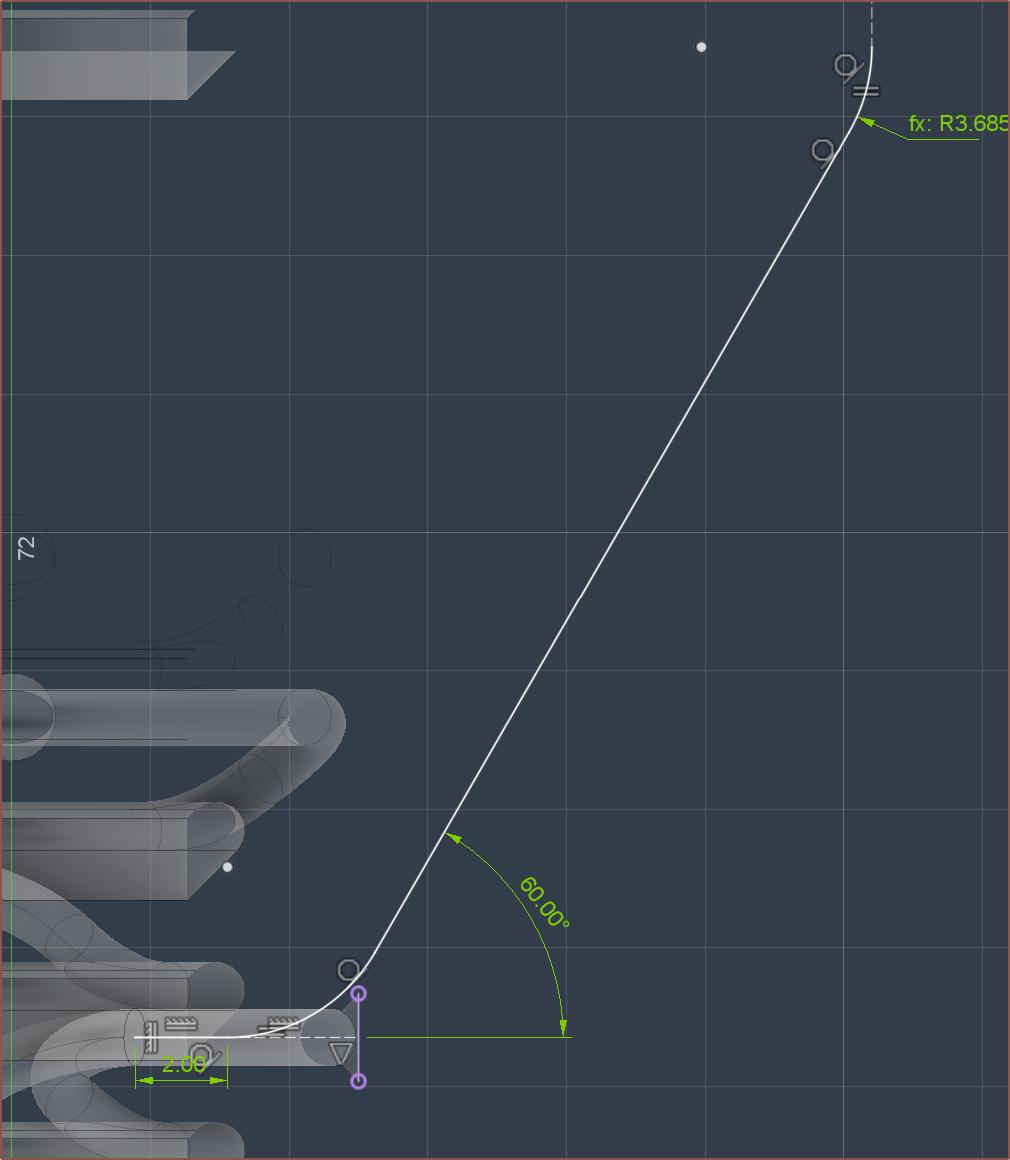

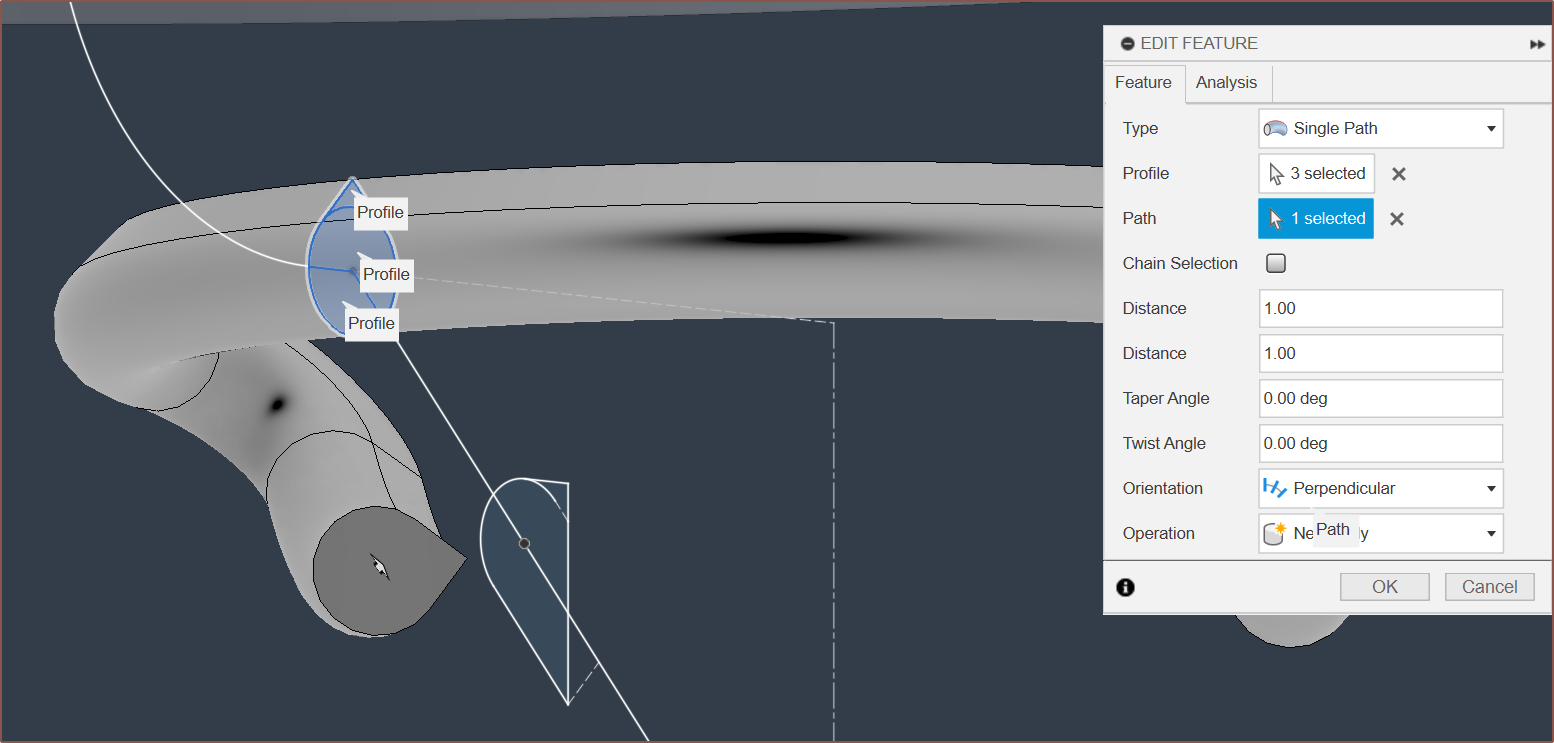

So as you may know, curves will cause the profile of sweeps to rotate:

It didn't know of any option Fusion had to keep the profile orientation the same. Thus, I went to r/Fusion360 and searched "sweep" just to see if there is anything I can learn from others that had their own sweep issues. From the solution video from this post, I learned that there are more than just "Single Path" types of sweeps. I successfully tried a few things and the simplest solution was to use the "Single Path + Guide Surface" option, whereby my construction surface is also used to keep the orientation the same:

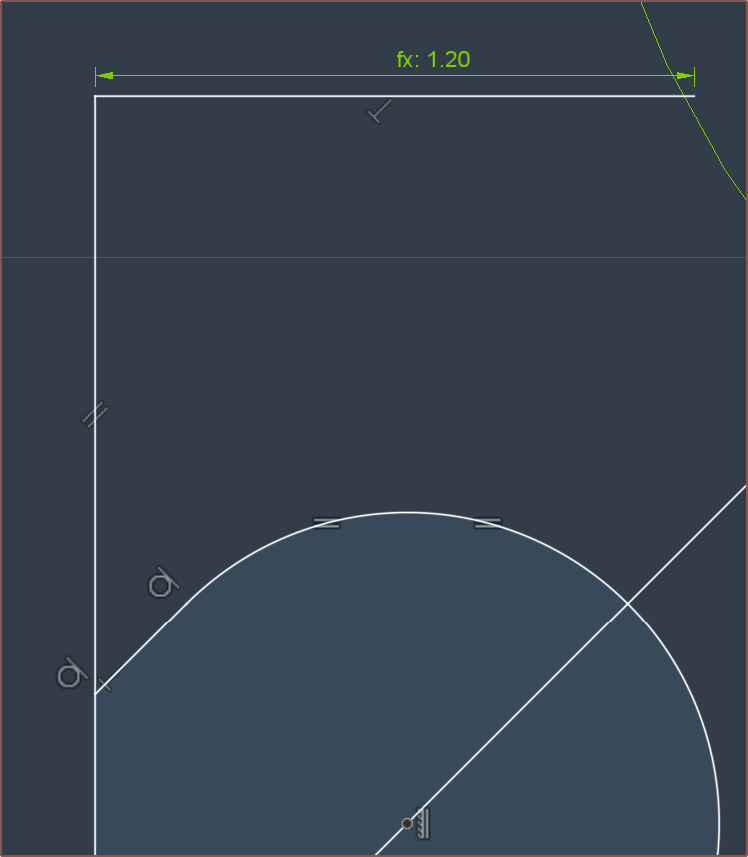

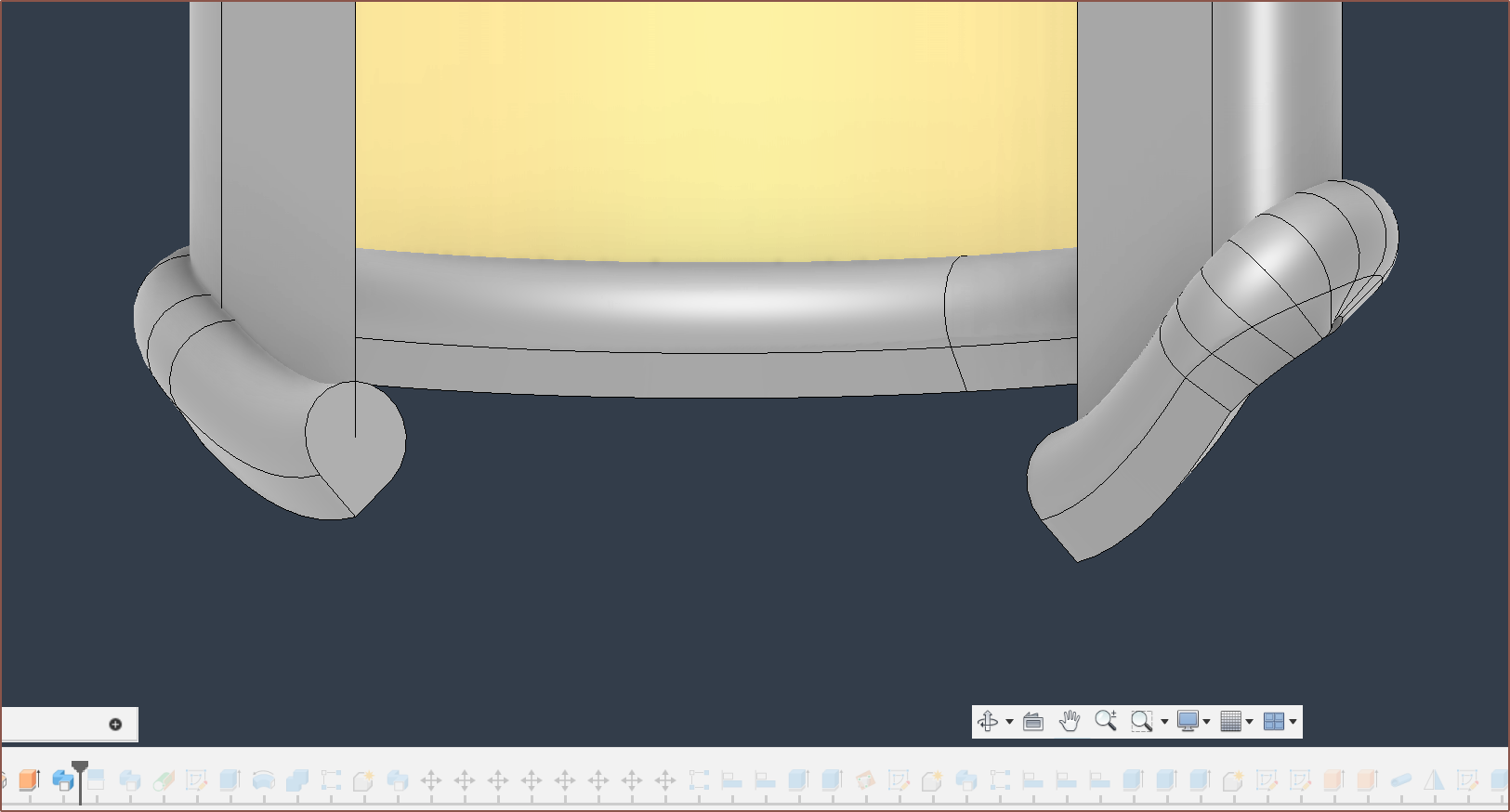

Next were the MajorChannel ports, which took a loft of half the profiles, offset face, delete face and some sweeps to get the result needed:

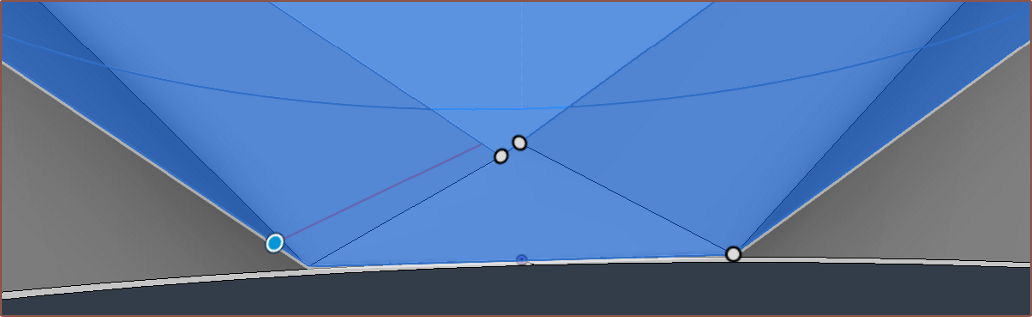

I had to have a 0.01mm flat section at the bottom since the loft tool wouldn't like it if 2 rails shared the same point:

Some more cutting and trimming and trimming and cutting later...

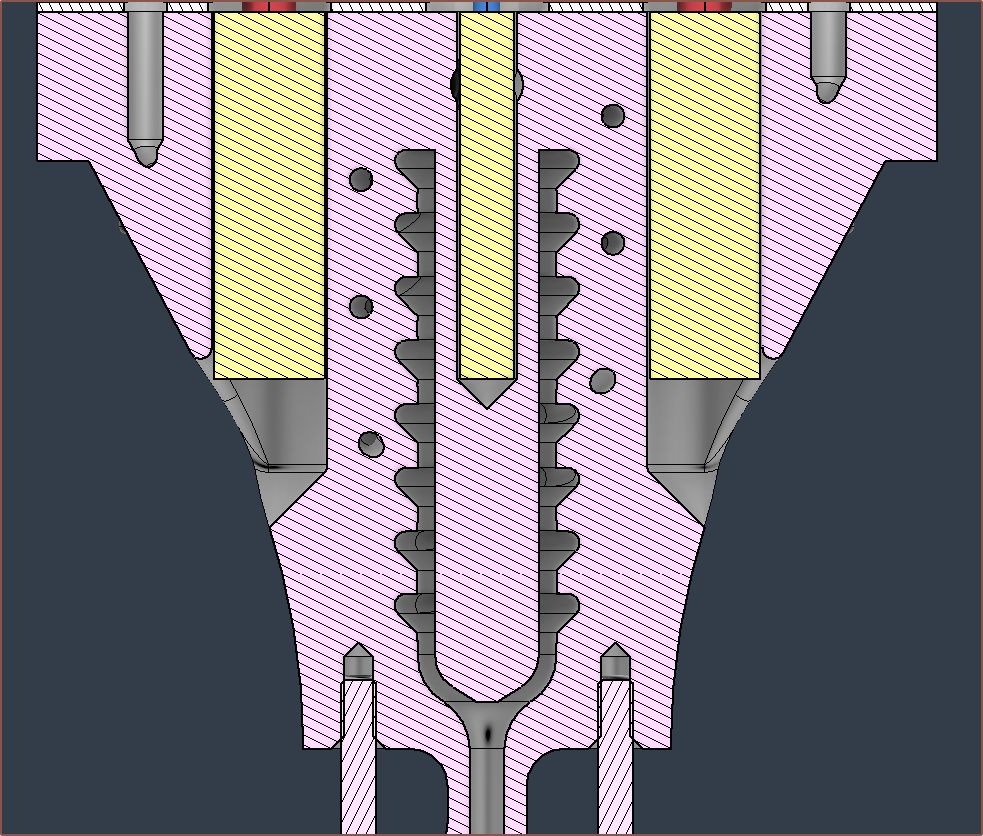

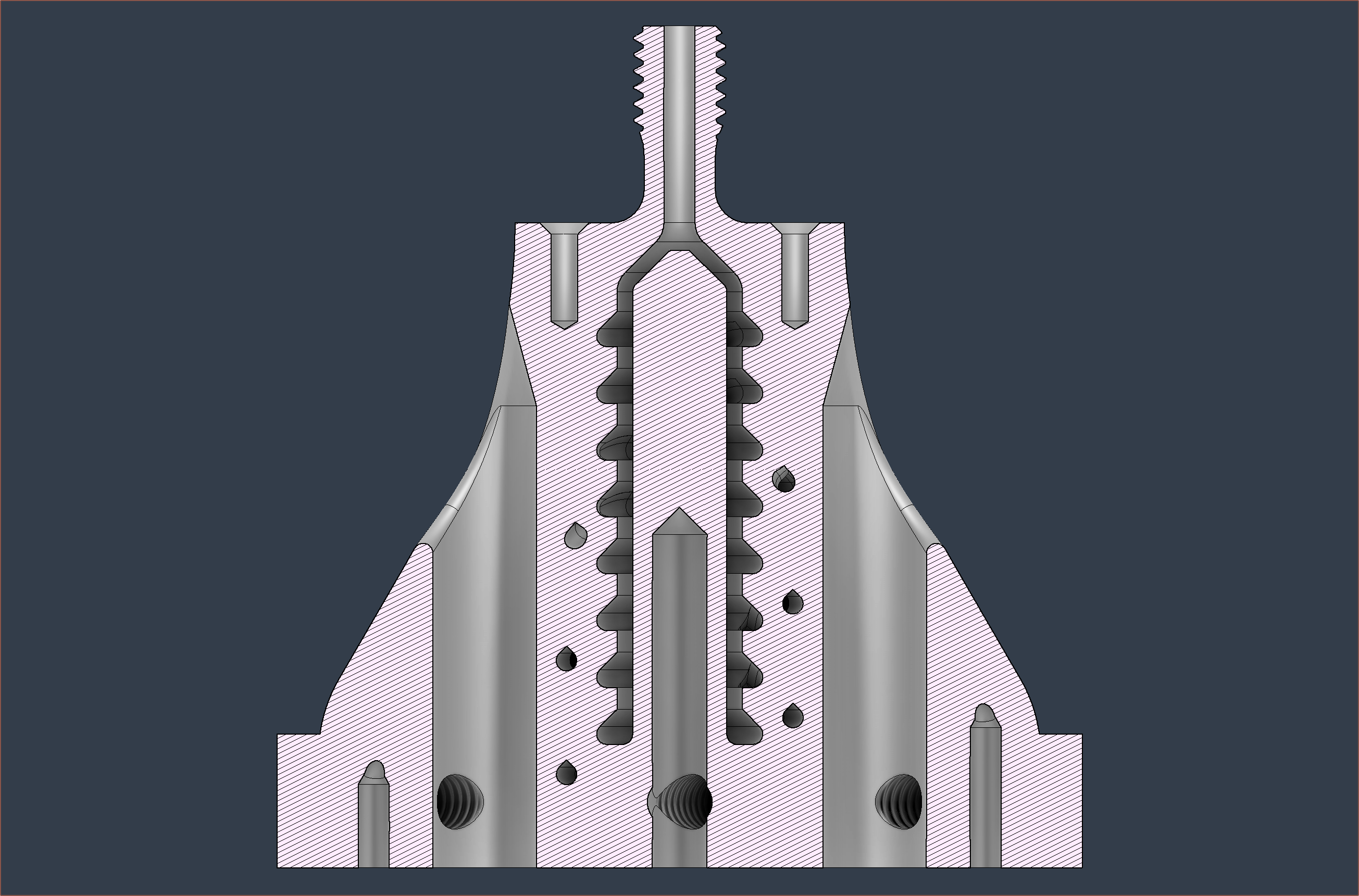

...I had a new solution:

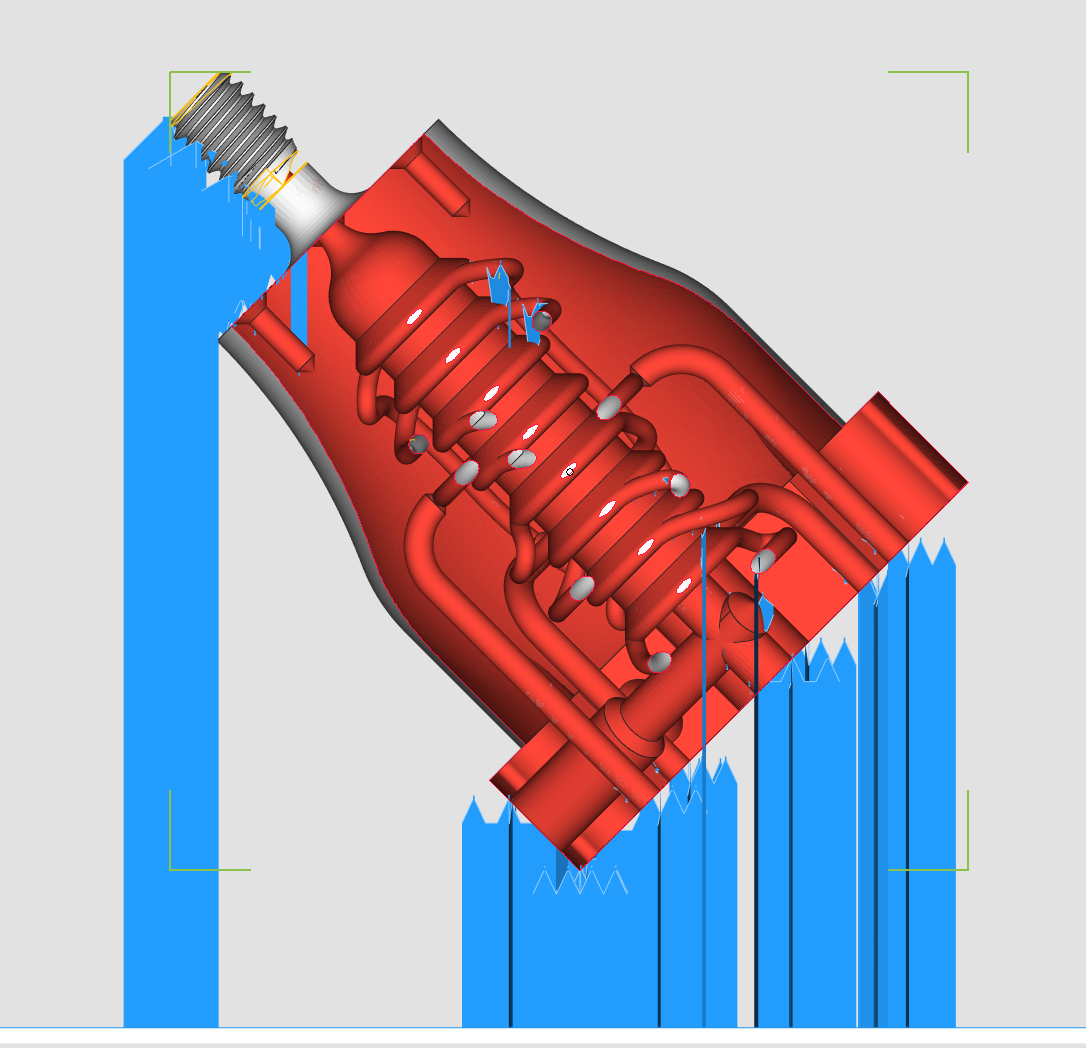

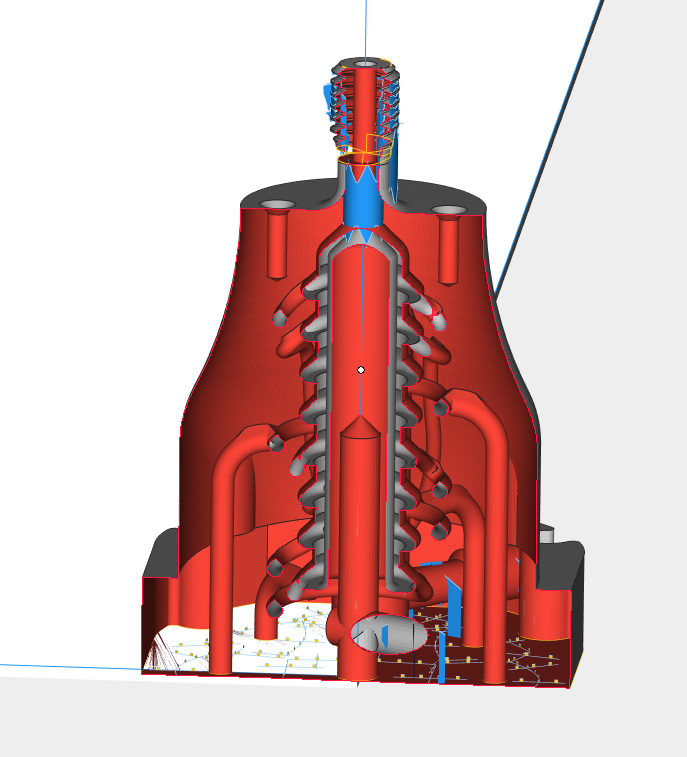

This is the Buildable:

Other than some mystery supports that hopefully don't need to be there, I think it's good to go.

Trivia

The part cost is $64.38 which is the same as the alpha-build I had quoted to see what kind of price-range this strategy would be in. The final cost is $83.66, which converted is a fractionally-round £66.67.

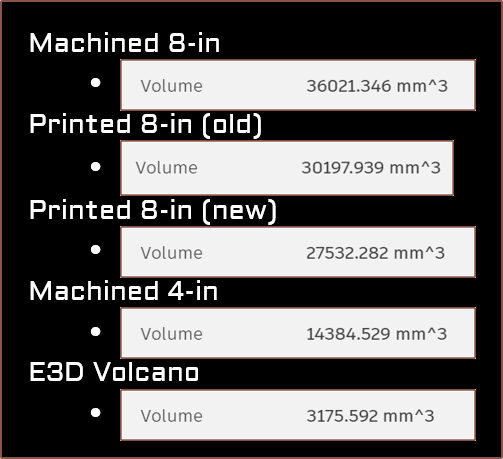

The volume is approx 27600 mm^3, which is 8.7X more than a volcano block. Thus, the input:volcano-volume ratio is 1.087 for this 8-in-1-out hotend, which is slightly lower than the 1.133 for the 4-in-1-out. It's interesting how this project both figuratively and literally tries to merge multiple hotend tools together.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.