I've got a list of problems, but "Does it coaxialise?" isn't one of them, guys!

8-minute level test

(or, 7m 57s to be more accurate)

Some days ago (this was supposed to be a log, but I forgot), I started a circular bed levelling test print. The idea was that it'll stop faster if I cancelled the print. I forgot that FFF is now in the arc-printing era and, as such, it still took a while between pressing the cancel button and the printer actually stopping.

This time, the reason for cancellation is because the CR600S suddenly had trouble extruding and it was reflected in the print looking like the nozzle was suddenly too close to the bed.

I confirmed that I had .51mm, an expected thickness, and then 0.08mm. Still, it was a promising test as I couldn't see any leaks.

I confirmed that I had .51mm, an expected thickness, and then 0.08mm. Still, it was a promising test as I couldn't see any leaks.

I've got an idea to improve the fan holder cover so that the hotend is better attached. At the moment, I can see that the hotend slightly sags forward.

Input shaping test

All these 2D prints have shown promise to coaxialise, but I wanted to know for certain. I preferred if I could print something more useful than a test cube, and so I had the idea to tune input shaping.

The first time was trying to use the quick test print gcode generator, but Reality has to defy expectations somehow and so M501 crashes the printer. This is the command that loads saved values. M500 and M503, to save settings and restore default settings, works without issue.

The actual gcode is 2D only though, and since I'm already experiencing bed adhesion issues, it was understandable that it didn't work.

I decided to disable my pushpull code just so that I could work on a firmware that was less likely to have things go wrong. It didn't help with M501, but turning it off helped me notice that the start gcode is commanding a massive retraction between the prime line and main print. I didn't know this happened the first time and so Ch1, filled with white, wasn't extruding. I used an allen key to push the material in and then reinstalled the bowden to rectify this.

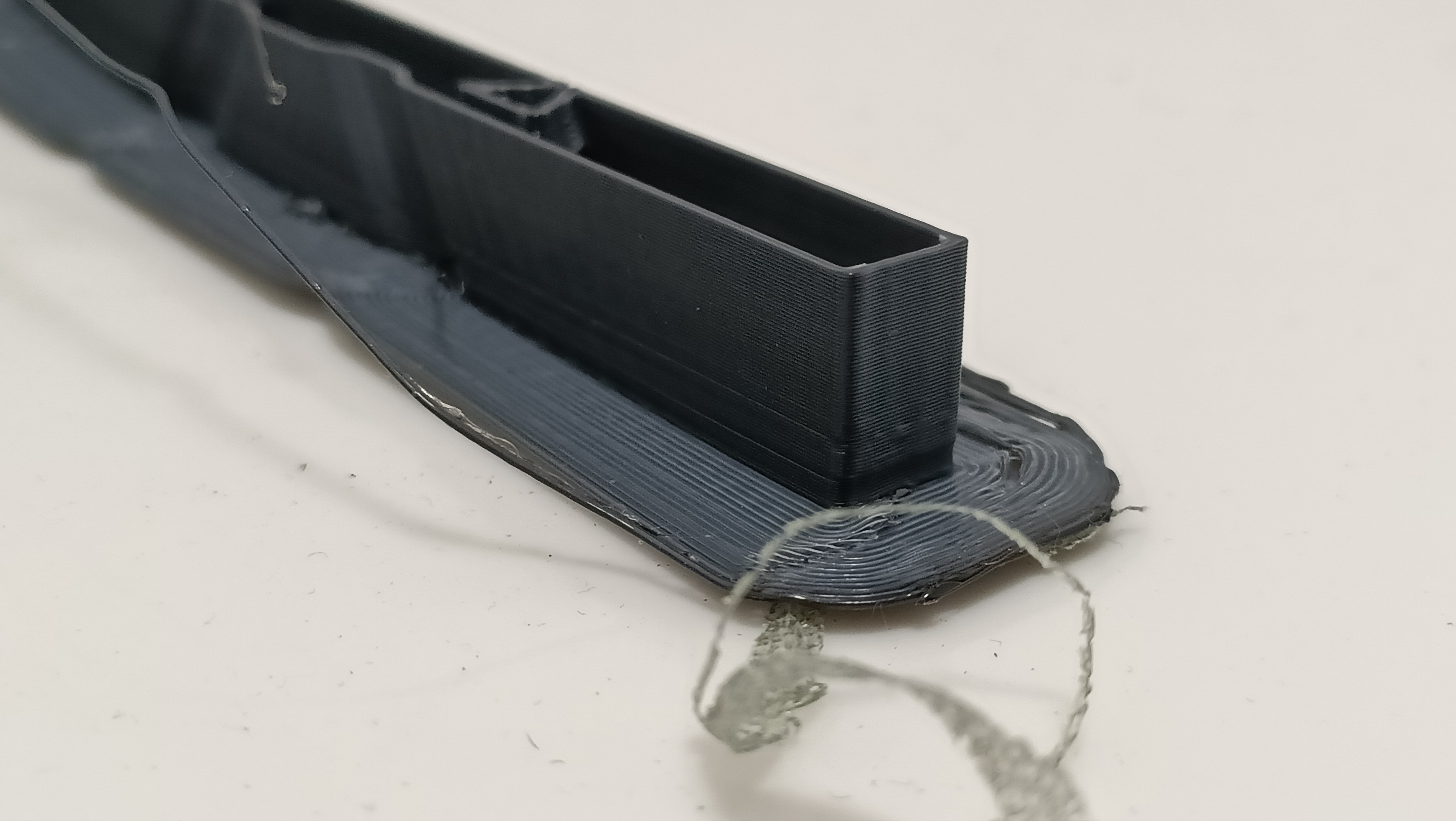

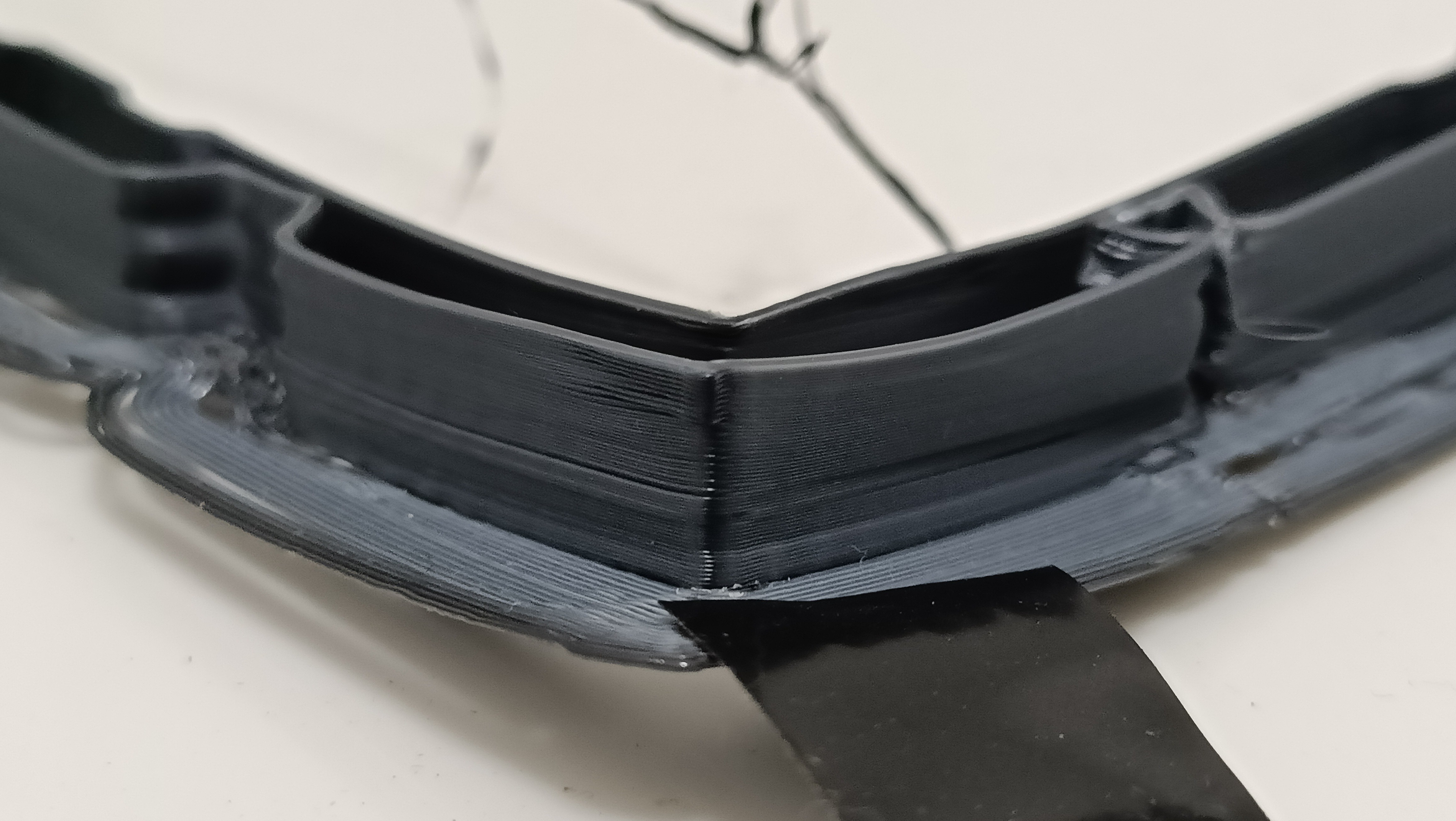

The second print was when I noticed the retraction issue so I quickly reseated the filament before it could re-block again. Material started to extrude, but for the most part, it wasn't sticking to the bed. Shockingly enough, it stuck enough to not immediately fall off the bed. I also saw a transparent-blue blob at the front of the Coaxial8or, but it wasn't growing quickly, so I let it continue until I thought it would be a waste of filament to print any more. The image below shows the print when I decided to cancel.

The result

While I have issues such as:

- M501 crash

- Bed adhesion

- Not 100% leak-free

- Heatsink and fan holders that need improvement

- Start g-code causing large retraction

- Shallow 90-degree bends limiting volumetric flow rate

- Transferring heat from the high-wattage heater cartridge

- The levelling tool on the TFT24 menu does not move Z to 0.0

The most important thing works, which is getting a consistent grey from white and black filament:

Unlike LK99, this should be a valid independent replication of Nozzleboss' and CNCKitchen's findings in that FFF filaments can be "mixed" by coating one in the other and relying on subsurface scattering to blend the colours.

Unlike LK99, this should be a valid independent replication of Nozzleboss' and CNCKitchen's findings in that FFF filaments can be "mixed" by coating one in the other and relying on subsurface scattering to blend the colours.

Unintended stripy-toothpaste effect can potentially be a thing of the past, which has been a known issue since the RepRap Diamond Nozzle was commercialised in 2015 (and possibly earlier)!

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Thats really impressive! What does a cross section of the extrusion look like?

Are you sure? yes | no

Good question. I'll have to reprint with much wider/thicker layers because I can't really make out the details after using a wire cutter on these 0.2mm layers. I'd also need to print with a different colour than white, as it's difficult to determine if the white I'm seeing is filament or light reflections.

Are you sure? yes | no