I was wondering if I'd need tolerances similar to the Tetoroidiv rotors and it seems like I do. Charts, machinist forums and Gemini all agree that, for a dowel 6mm or less, the "interference" should be 0.0005 of an inch for a press fit, though one forum-user was able to work with 0.001. In other words, the holes are between 12.7 to 25.4 microns smaller than the precision round object that's going into it. I also found the below video that recommended that the initial hole should be smaller by 70 - 140 microns for 1 - 3 mm holes respectively, meaning that for a 2.5mm reamer, I'd be using a 2.4mm drill to enlarge the roughly printed holes.

Now, since the rest of the world works in metric, the only options for reamers are 2.49 or 2.48mm. Gemini determined that 2.47 would be too much for a solid dowel pin, let alone a thin-walled tube. Speaking of the tube, my plan is to use 1.9 ID x 2.5 OD tube so that there is a tad less expansion space for the molten material and the tube walls give a little more strength than 2.0 ID.

2.49mm is closest to what all the forum-users are using, but Gemini and I did the thermal expansion calculations and the interference would loosen by 4 microns (aka 40%) when heated up to 250C and up. This isn't really an issue for copper, such as the Creality Unicorn nozzles, as both materials have rather similar expansion. I'm considering printing the heatblock in stainless steel from JLC since both the tubes and the cross-dowel pin is stainless steel. I know Dyze uses a non-stainless steel, and in the comments they said it was because of higher thermal conductivity. Obviously, as I've found out in this project, stainless steel is tough stuff.

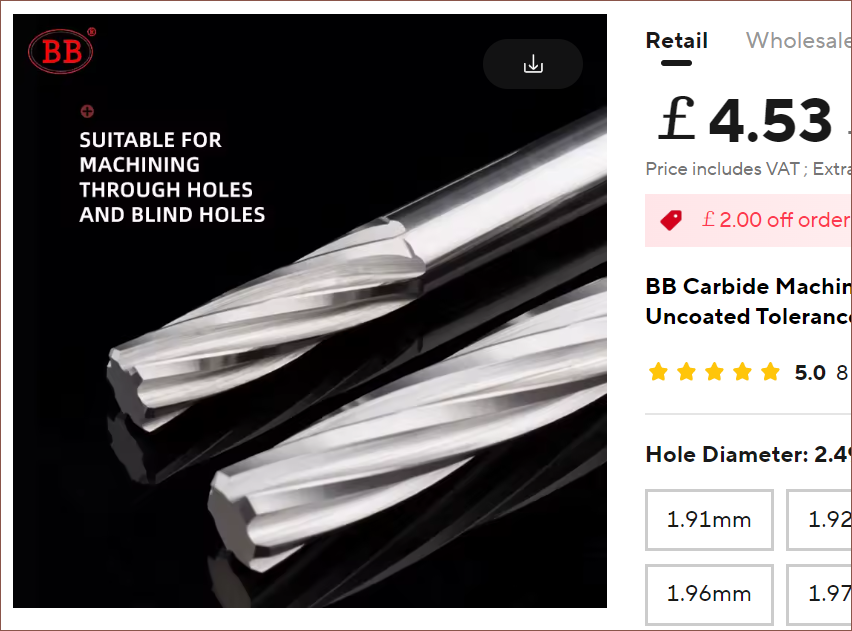

I found some low-cost reamers and drill bits on AliExpress. I thought they'd be way more expensive. I'd have to spring for the coated ones from the other supplier I found if I go through with a stainless steel heatblock either now or in the future:

2.49mm feels a tad too close to the limit, especially since the whole system is pressurised too and there are 8 of these that need to be confidently installed, thus my first choice will be 2.48mm. There's also the option of lightly sanding down the tube if it's too small.

Allegedly, to actually insert the tube, I'll need something called an Arbor Press, which exerts forces measured in tonnes allegedly. I found a white, branded one that does 0.5 tonnes for around £50:

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.