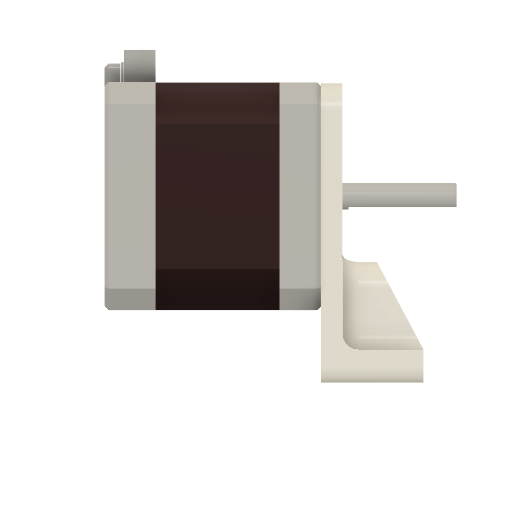

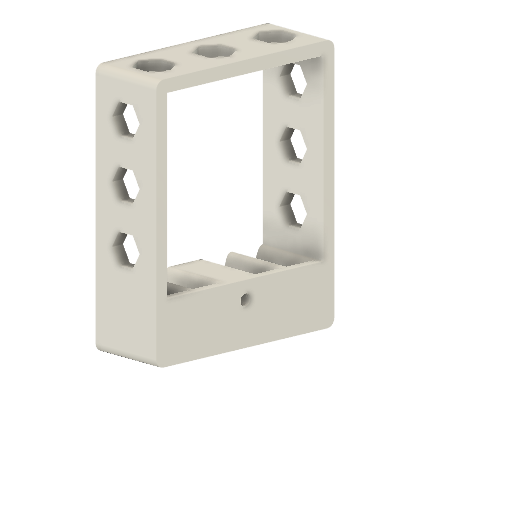

In previous version of BrailleRAP the Y motor support whas this one :

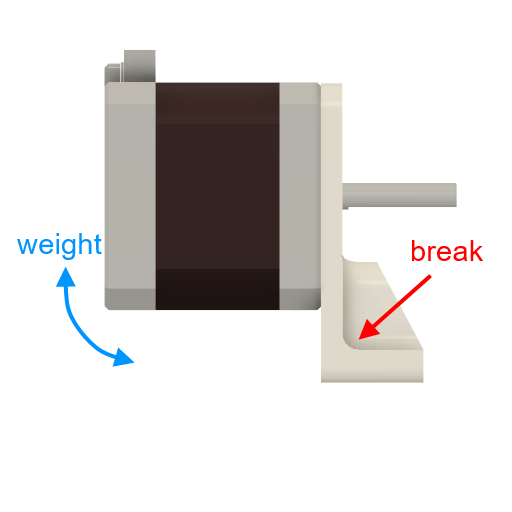

As the support work well, the 3d plastic deigned part sometime break at the layer jonction. Even if the BrailleRAP was packed in foam, plane travel in cargo hold was hazardous for the support. We analyses the problem and thought that the weight of the motor with the big cantilever created by the design, could bend the support between the horizontal and vertical part.

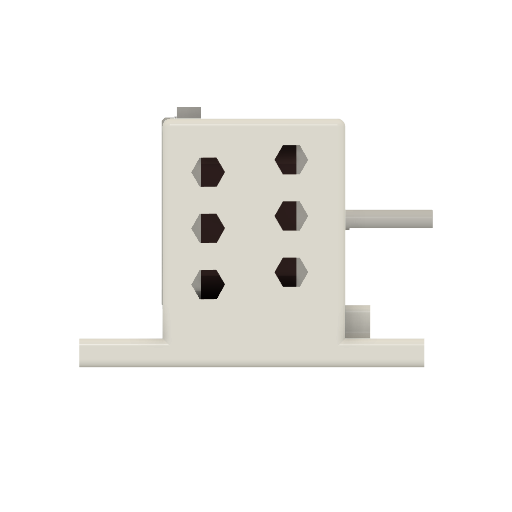

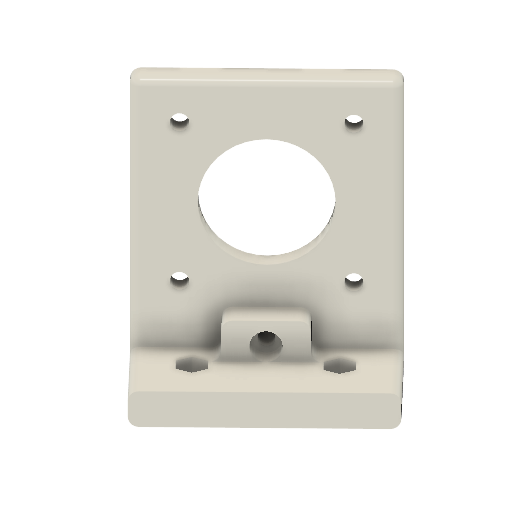

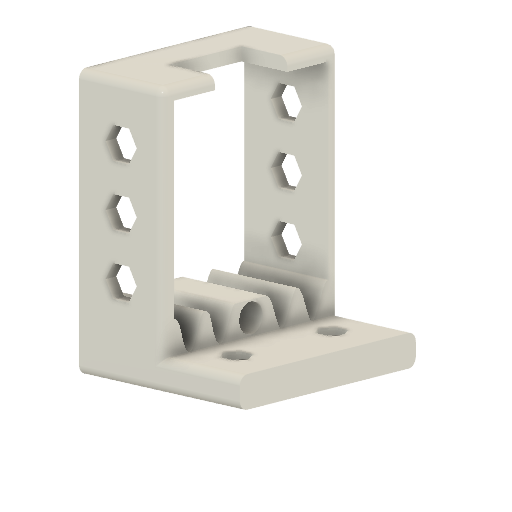

The goal was to kill the cantilever, adding some support on the motor back that we can secure with some screw on the frame. So we design a support like a cage, securing the motor in the cage with standard screw fixation of nema17 but now the motor do not have the ability to bend the support.

As the support is not easy to print one a standard 3d printer, we cut it in 3 parts, allowing the user to build the support himself by securing the 3 parts with 2 screws.

That's it the Y motor is now firmly attached to the frame with 4 screw and you still can adjust the motor position to tension the belt.

Stephane

Stephane

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.