I've suspecting that my tips are not optimal.

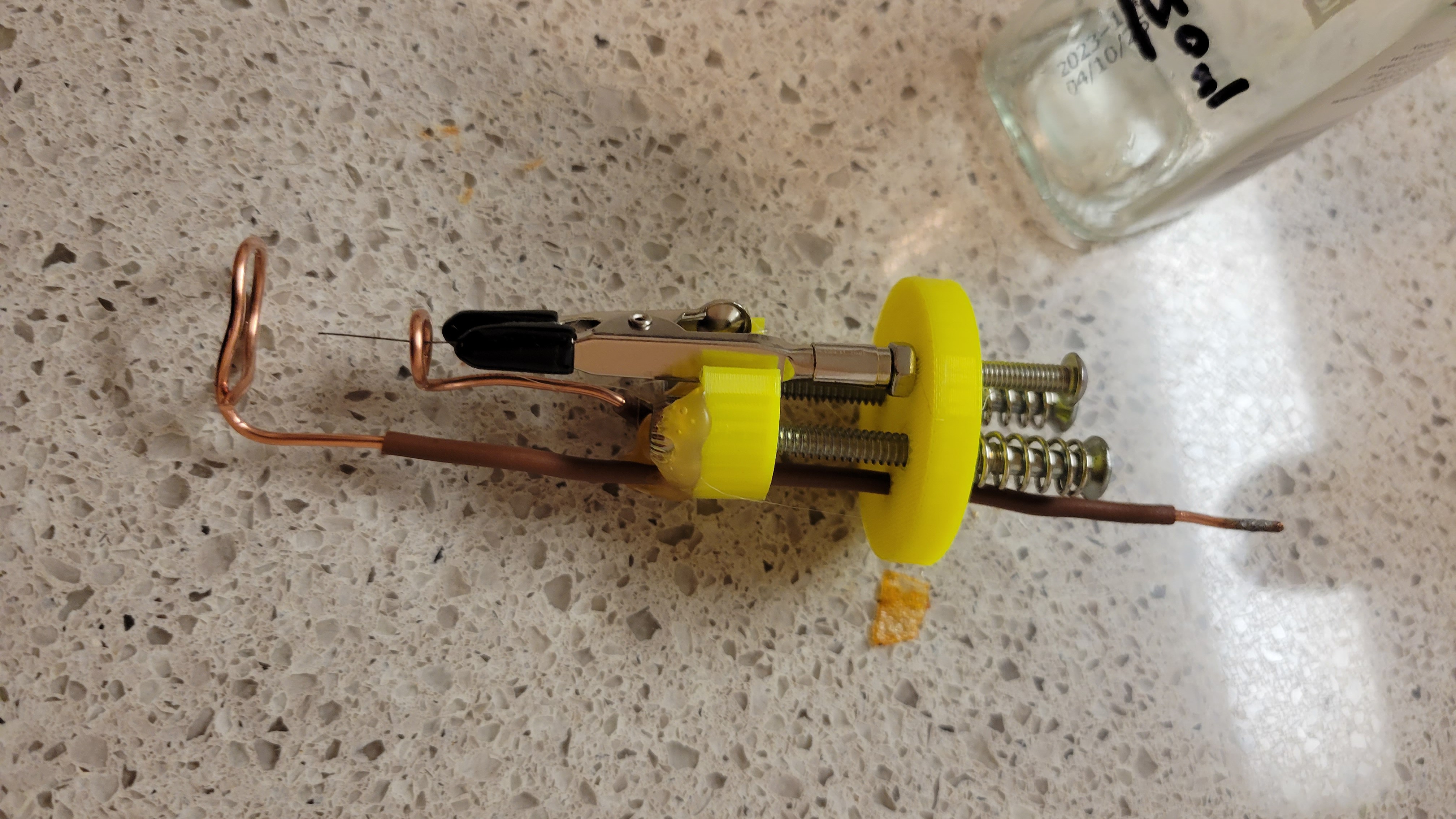

One of the problems with my prototype was that the wires were hard to bend into the right position. Now I made this assembly to hold everything in a much easier fashion and use suspended ring. Another reason is this configuration doesn't require Tungsten wire to be connected to as cathod, thus we can make it extremely short while it's connected to Quartz tunning fork.

The idea is to have a springs, by pushing springs down get solution into the small ring.

Once the Tungsten wire snaps it will cut electric current this making the tip much sharper (in my previous design I had to stop the current manually. This short time might de-sharpen the tip)

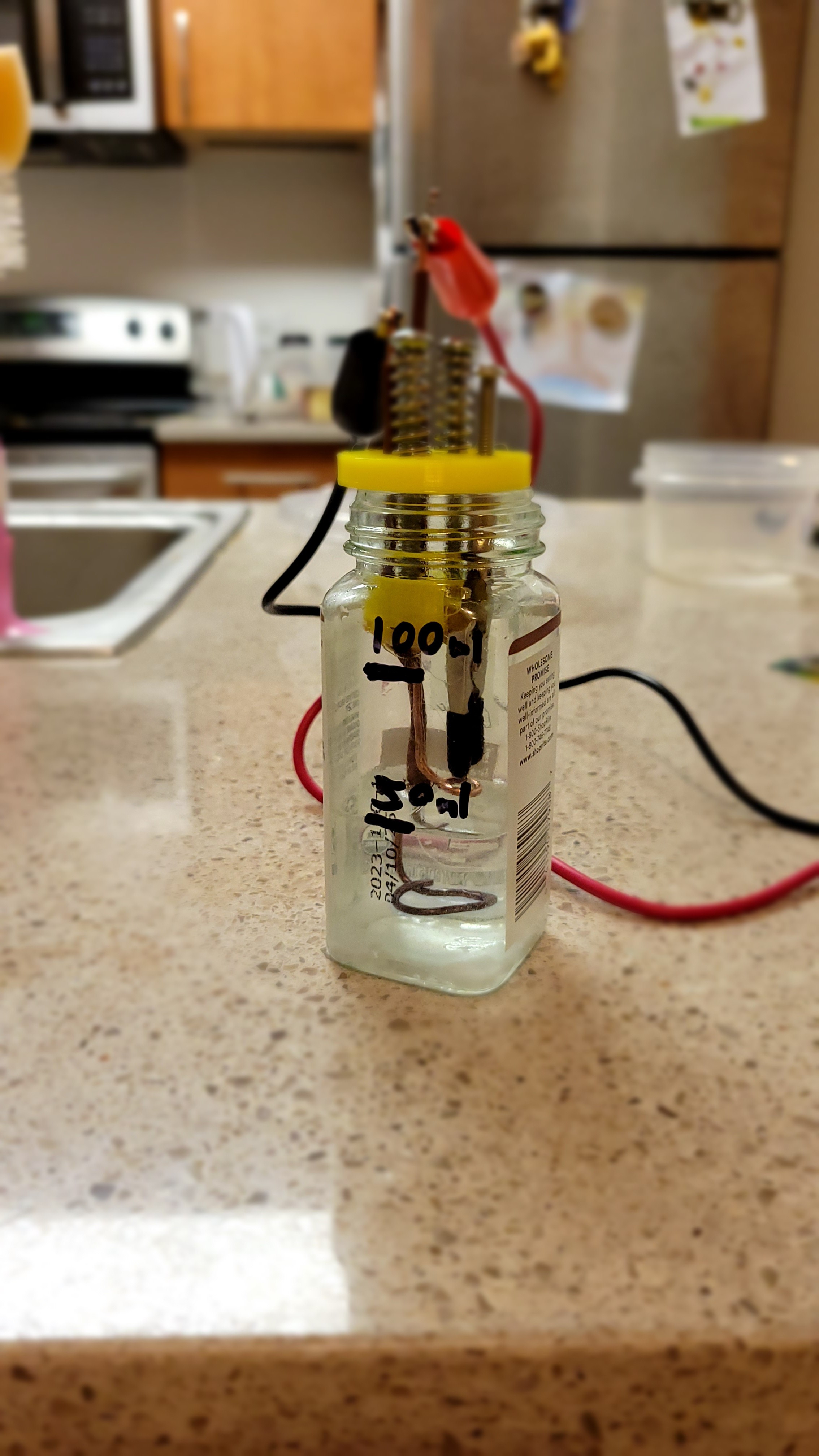

It should run like this

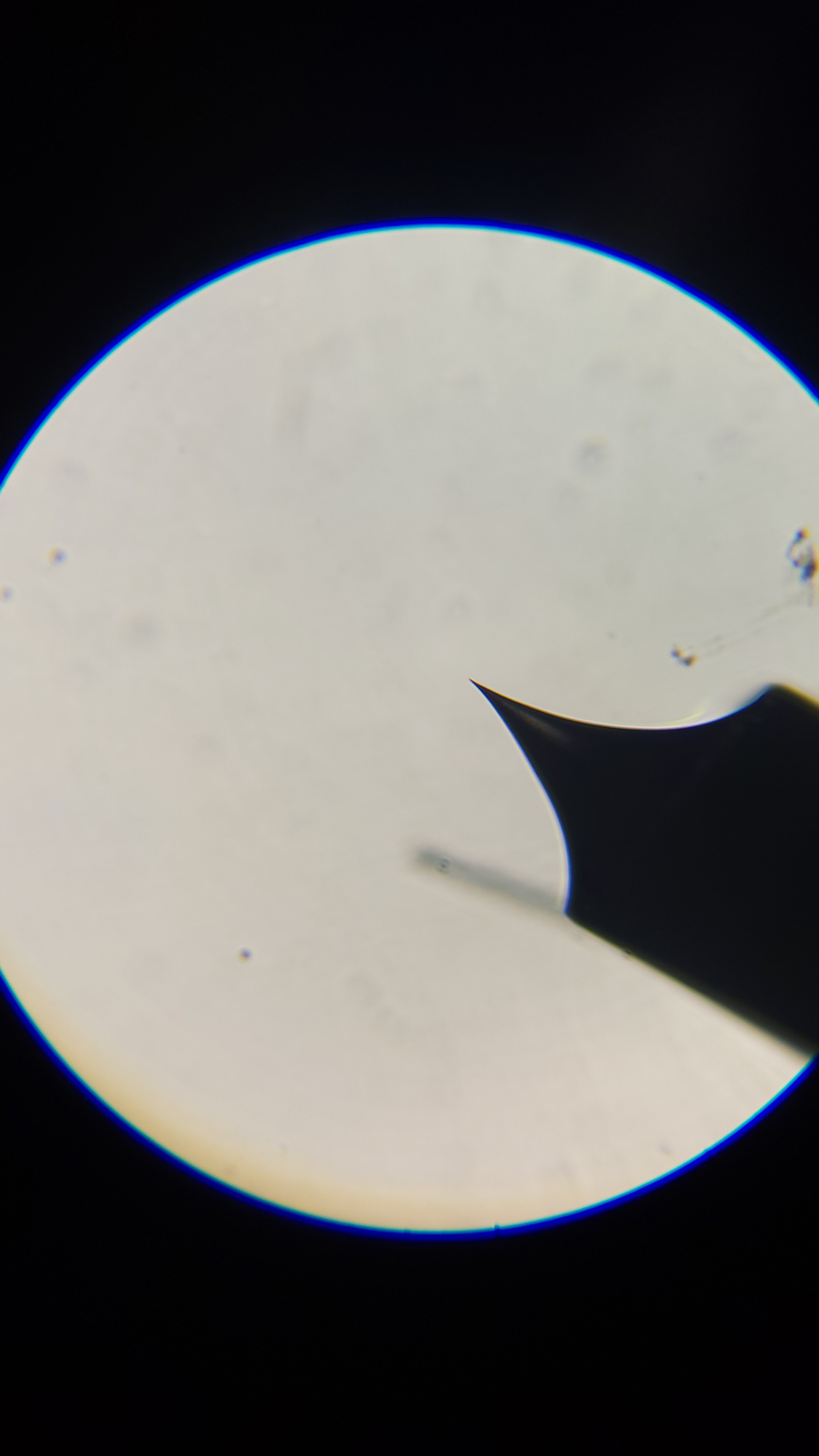

And the result is (after about 90 minutes)

Again I've managed to bump (twice) this sensitive needle into the ring(after I've crushed quartz fork)[Sometimes I am a disaster]. As a result the tip was bent. But we clearly can see the tiny tip much smaller than my previous one. Actually this is a design problem. The ring is held by lower holder and the Tungsten on the upper. I should redesign so both the ring and Tungsten holder are attached to the lower part.

You can find the STL files on https://github.com/100dollarhacker/atomic_force_microscope/blob/main/AFM_tiip_creator_part1.stl

Third time ice cream, with the new part it was much easier

And the result

Now that is what I call thin! (The wide part is only 0.2mm)

It think I should change project main picture 😄

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.