TL;DR: WHAT I THINK IS COOL ABOUT MY PROJECT

- F1 inspired design: Twin 7-segment LCDs on top with a rotary knob in the center, flanked by buttons on either side. Look up "2010 F1 steering wheel" to see what I mean.

- Accurate timekeeping: Timekeeping is pretty accurate, it drifts around a bit but never for more than I second I think. Chronograph is also pretty accurate. Millisecond precision.

- Various sensors: It has a 3-axis accelerometer and an environmental sensor package(temperature, humidity, pressure, altitude) but I can't get them to work for some reason. Also has a battery fuel gauge IC

- Retro design: Besides F1, the watch was also inspired by vintage cars, Kaneda's bike from Akira, and Unit-02 from Neon Genesis Evangelion. The watch has "fender flares" on all four corners, inspired by cars like the Fiat 131 Abarth, Lancia Stratos, and Lamborghini Countach 5000 Quattrovalvole. The LEDs are green to mimic the green "motor-coils" from Kaneda's bike, and the similar colorway of Unit 02 from NGE.

- Neat PCB artwork: Of course, design is subjective, and I figure some people won't agree, but I really, really like how the watch turned out. I spent way more time than I should getting the design flashy, but not overly busy, and I think I got it right.

- Personal story: I made this during my required service for the South Korean military, one of the hardest times of my life, and it means so much to me. While TM8 is by no means impressive from a technical/skills point of view, I wish it showed others just how strong my passion is for engineering and design. I absolutely love what I do and TM8 is the physical manifestation of that love and passion for my work and what I study.

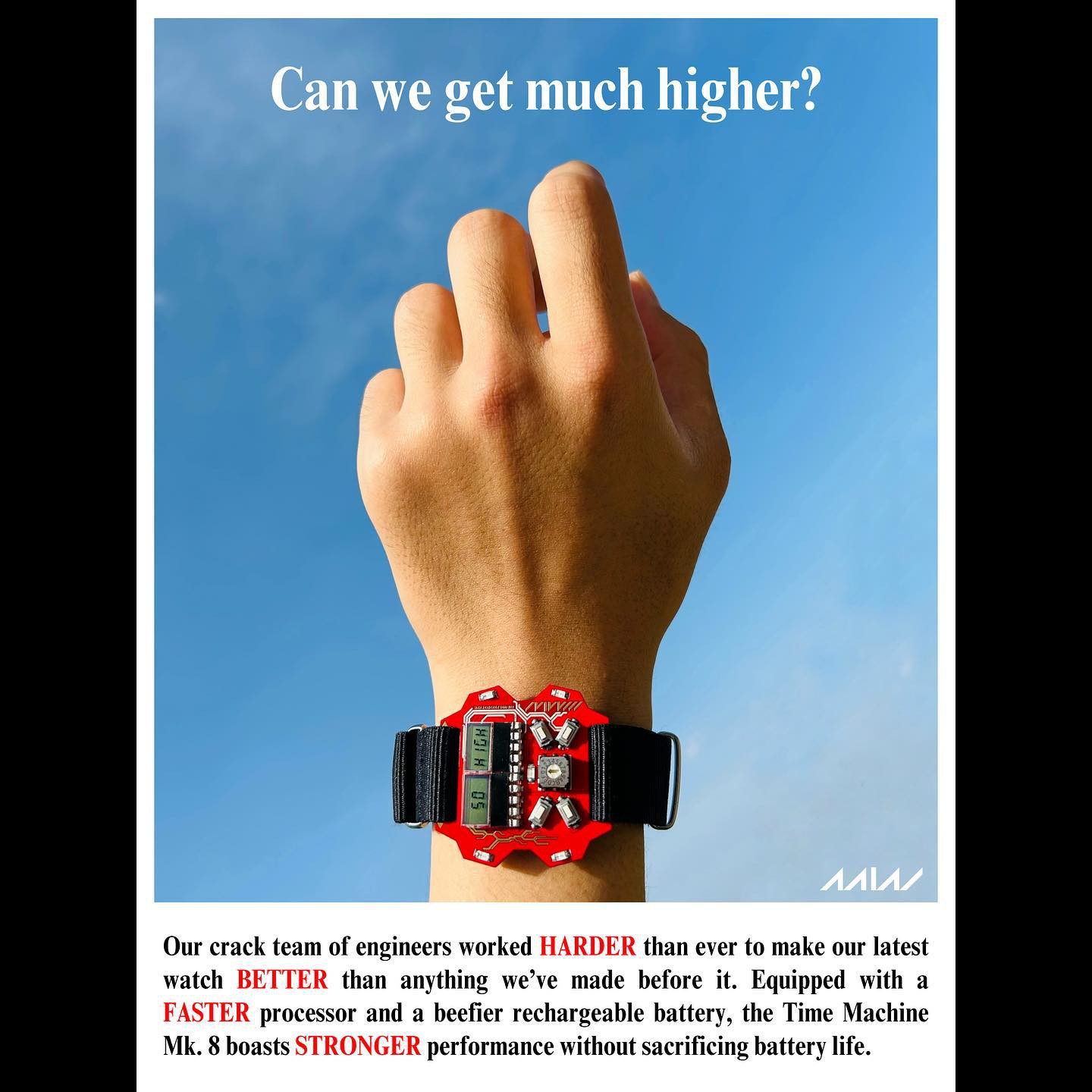

^ Kanye West inspired ad I made (I'm a big fan of his music)

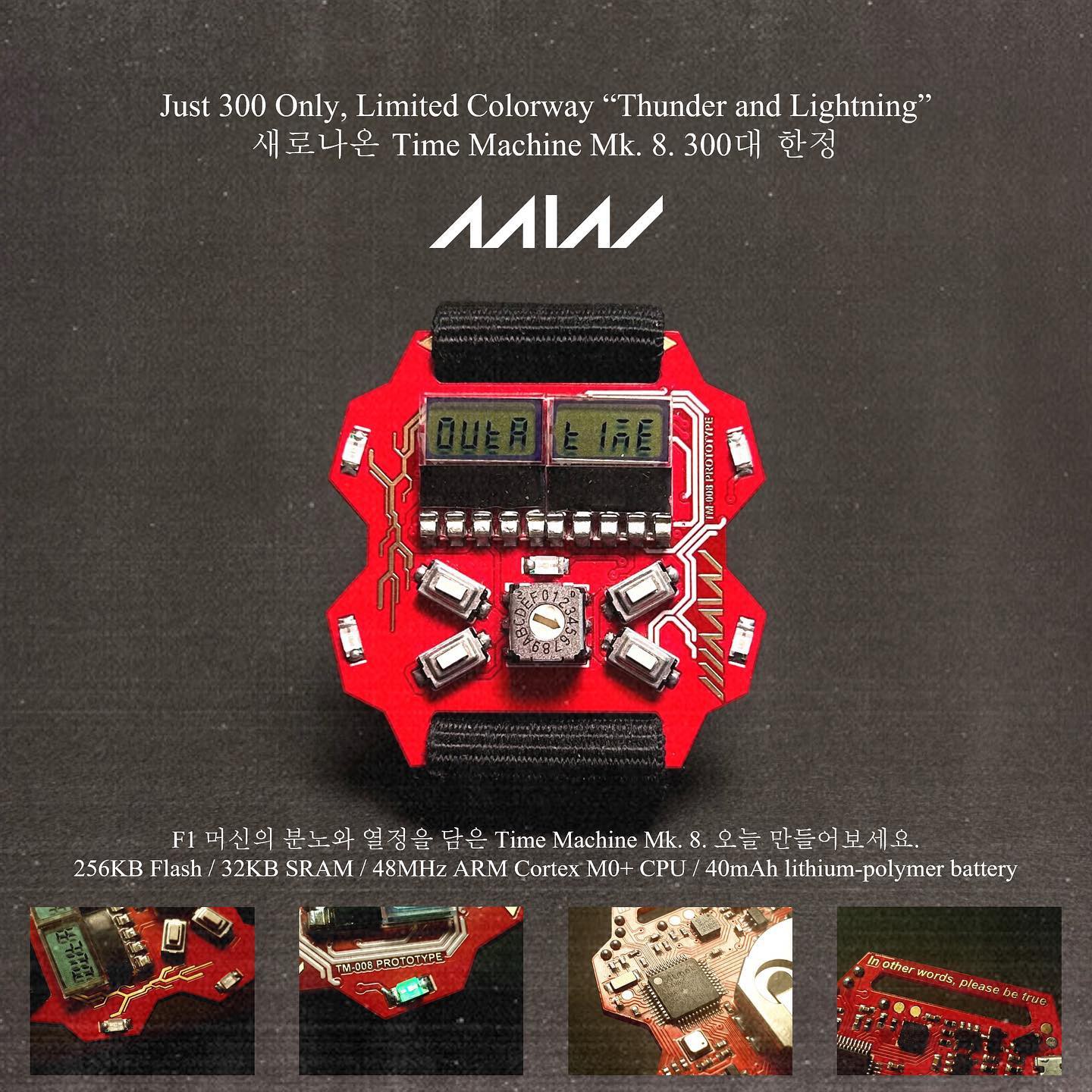

^ another fake ad I made inspired by an old Japanese brochure for the R34 Nissan Skyline GT-R (I really like cars)

Ok now let's get serious!

DESIGN

Overall design: Chief Design Engineer Eric Min

The Time Machine Mk. 8 is a huge step forward in terms of technological prowess and design goals. While previous generation Time Machines were very simple watches cobbled together without much thought, TM8 is our first product made with focus on a singular goal: maximum performance and style at the lowest possible power consumption. We wanted to retain the iconic design language of our previous Time Machines, while still incorporating the numerous new features of our new model. This proved much harder than we initially thought, but at the end, it couldn’t have turned out any better.

Ever since the Mk. 2, the Time Machines’ muscular and angular lines have been an integral part of its design language. With the Mk. 8, we reprofiled the “fender flares” to be better proportioned with the rest of the chassis, as well as mimic the look of the muscular bulged fenders of classic 80’s cars, such as the Fiat 131 Abarth or the Lamborghini Countach. More importantly, while the fender flares were simply a design element in previous time machines, it actually serves a functional purpose in the Mk. 8 since it provides valuable PCB area for the numerous new functions we added to the watch. Without them, we wouldn’t have been able to cram in all the features we had planned.

Ergonomics & Front Fascia design: Systems Designer Eric Min

The front fascia is a radical departure from the usual two-digit, three-button layout familiar in previous generations. Our team decided two digits was not going to be enough for TM8, since with its new telemetry sensors, the watch would have to relay more information than just time. It took a painfully long time to look for and decide on the right display. Near the end, our team narrowed it down to two options: a 48x64 OLED display, or a 4-digit 7 segment display. We eventually decided on the latter as it fit better with our retro-futuristic design. While the OLED display was significantly cheaper and had better graphics, the design team concluded it would look awkward with the rest of the watch, and was therefore sacked. We trusted our software team to squeeze the most out of the LCD’s limitations. After all, working with and around limitations is what we do best. Furthermore, not only would the LCD provide significantly lower power consumption, the design team also fell in love with the fact that when two of those LCDs were put side by side, it resembled something like a Formula 1 steering wheel. Which brings us to the buttons…

While Min Works solely works in the electrical domain, we have always been fascinated by all things mechanical, automobiles being one of them. One day, I came up with the novel idea of making the Time Machine Mk. 8’s front fascia resemble an F1 steering wheel. Skeptical at first, our design team quickly landed on a design that made excellent use of available space without compromising usability and design. The final design has a central rotary “cooker” knob, flanked by two tactile momentary switches on each side, with twin LCDs on top to make an 8-digit display. The five auxiliary LEDs were carried over directly from previous generations, placed in parallel with the fender flares like the Mk. 4. The result is an extremely unique design that satisfies all our target design goals without compromising practicality.

The central cooker knob provides a new method of user input, not too different from the digital crown in an Apple Watch. The 16-step cooker knob provides a satisfying click with each actuation, and we think the engraved hexadecimal codes provide extra design flair to the watch. Unlike a conventional rotary switch, the one on TM8 outputs in 4-bit parallel BCD, meaning our software doesn’t have to track and store actuator position, making firmware development significantly easier.

The flanked buttons were angled to provide a more aggressive look, but also to provide enough distance apart so that a finger could feel and press the buttons without the user having to look at the watch. This would be useful in situations such as lap timing, when the user would have the watch strapped to a steering wheel. Being able to “touch-type” would be crucial during such instances.

Livery & Aesthetics: Graphics Designer Eric Min

The design team was at first a bit afraid that our design goals of incorporating twin LCDs and a cluster of buttons and switches would limit PCB space for a livery, but at the end we ended up with significant space left for artwork. Our livery design took more development time than we would like to admit, but the end results are simply phenomenal. Our team dubbed the TM8’s design, “Thunder and Lighting.”

On the left, we have exposed copper artwork of a thunderbolt, painstakingly designed to fit in well with the overarching aesthetic of the watch. It took us quite a long time to land on a design that was visually striking but not overly busy.

On the right, our circuit design engineers worked in tandem with the design team and took some liberty to route copper traces that would work both functionally and aesthetically. When PCB routing was finalized, the design team overlayed select copper traces with white silkscreen to make a “lightning bolt” of signals. Like “thunder”, “lightning” also took quite a bit of time in coming up with the overall design, selecting which traces to paint white, and which to keep red. Accompanying “lightning” is a stylized Min Works logo, along with a small “TM-008 PROTOTYPE” script nestled into the upper-right corner, both in exposed copper.

Often, the design team was split into opinions of how our livery looked; some thought it was too busy, while others thought it was a bit subtle. Much debate and discussion went on between these parties, but we eventually reached a nice middle ground that gave just enough visual pop without being too loud.

For the lugs, we took inspiration from Unit 02 from Neon Genesis Evangelion. With Red being our representative color, we found Eva Unit 02 to be the perfect design inspiration, which we took in the form of exposed copper scripts on the lugs. On the front, they designate the model number and on the back, we have lyrics for Frank Sinatra’s Fly Me to the Moon, a tribute to Min Works’s founder Jihong Min, who is an Evangelion afficionado. Additionally, the lugs were reduced from 22mm to 18mm, and the lug hole corners were chamfered in for better structural rigidity, as acute angles are more prone to mechanical stress than obtuse angles.

HARDWARE DESIGN

Overall hardware: Chief Technical Officer Eric Min

Designing any embedded system is no easy task, but it was especially hard for Time Machine Mk. 8, where our primary goal was to cram as many features as possible into the smallest amount of space while using the least amount of power. Before anything else, our hardware design team came up with a list of hard rules that would set the limitations for designing Time Machine Mk. 8:

- The watch must be smaller than any previous Time Machine, without any compromise on previous features.

- PCB should be 2 layers with minimum trace width at 8 mils, and minimum via diameter at 0.3mm

- The battery must be rechargeable, and charging should be fully contained on the PCB without the need for any external circuitry.

- The battery must be a 40mAh LIR2032 Li-Po coin cell, soldered directly to the PCB for minimum thickness.

- The microcontroller must deliver high performance with low power, with an RTC, native USB, and at least two I2C buses required.

- The watch should do more than simply measure and tell time.

- Only the LCDs, LEDs, and buttons are allowed on the front side. All other components should be away from view at the back, or under the LCD glass.

Our engineers followed this set of rules throughout the entire design process, and while we were temped to break some of them, especially rules 1 and 2, we eventually developed TM8 as a fully self-contained package satisfying all our design goals.

Microcontroller: Embedded Systems Engineer Eric Min

With so many incredible microcontrollers available for dirt cheap on today’s market, it was pretty tough deciding on a micro to power our latest watch. Our team was focused primarily on ultra low power performance, and we flipped through hundreds of datasheets and manufacturer reference pages while narrowing down our choices. We decided early on to choose a 32-bit processor, as the current crop of ARM Cortex microcontrollers offered excellent computational performance while also killing the low-power game. Our requirement of a real-time clock and two I2C buses were also nowhere to be found on any 8-bit micro. After some research, our team whittled our list down to five choices: Espressif’s ESP32, Nordic’s NRF52832, the Raspberry Pi Foundation’s RP2040, Microchip’s ATSAMD21G18, or Silab’s EFM32 Zero Gecko, in descending order of performance.

We finally decided on the ATSAMD21G18 since we believed it gave the best performance and peripheral set with uncompromising low-power consumption, along with an incredible community of fellow engineers to rely on with any technical issues. The chip’s high popularity also meant we had no shortage of excellent reference designs to follow, such as Adafruit’s Feather M0 or Sparkfun’s 9DoF Razor IMU. We especially found the SAMD21’s SERCOMs extra appealing as it gave us incredible flexibility when routing our PCB. We didn’t have to worry as much about parts placement as we could simply assign I2C buses to pins best placed for the job. While the ESP32 and NRF52832’s wireless peripherals were pretty enticing, the team concluded that high power consumption during moments of wireless activity defeated the watch’s purpose. With a 40mAh battery, any sort of wireless radio would drain the battery pretty fast. Plus, their lack of native USB meant an automatic no from the get-go.

The SAMD21’s real-time clock (RTC) was also incredibly handy, as it allowed us to keep track of time without any CPU overhead and minimal power consumption.

Sensors: Telemetry Engineer Eric Min

As stated in the requirements above, we wanted Time Machine Mk. 8 to be more than just a time-telling device. Unlike previous versions, which didn’t do more than tell the time, the Mk. 8 is a genuine precision tool capable of measuring, recording, and analyzing various telemetry data. With so many incredible sensors available off-the-shelf, we took our time deciding which sensors to use, before landing on three: Analog Devices’ MAX17048 fuel gauge, Bosch Sensortec’s BME680 environmental sensor, and ST Micro’s LIS3DH 3-axis accelerometer. The first one was a no-brainer: while we considered implementing a rudimentary battery gauge using an ADC pin, we figured an external sensor’s higher accuracy and simple I2C communication was worth it. The BME680 offered a thermometer, humidity sensor, and barometer, while still boasting incredibly low power consumption, giving us an excellent low-power, high-performance sensor package. While we wanted to use Invensense’s ICM20948 9-DoF IMU, we couldn’t find any PCB space to incorporate the sensor’s required 1.8v power regulation circuitry. We figured the next best option would be a 3-axis accelerometer, and the LIS3DH offers great performance for low power. These sensors, coupled with the lean and fast ATSAMD21G18 processor, allow for incredibly fast telemetry acquisition and computation in real time.

Battery: Low-Power design engineer Eric Min

Pretty much everything in TM8’s design process revolved around the battery. We decided early on to incorporate a coin cell battery directly on the watch, just like previous Time Machines, to make it as thin as possible. While this would hurt its battery life, slick aesthetics was also one of our main design goals, and we believed in our low-power design team to work their magic to squeeze the most battery life out of the SAMD21 as possible. We decided to go for a rechargeable battery to mitigate this loss. Luckily, there was an off-the-shelf rechargeable alternative to CR2032 cells, the LIR2032. Being only 40mAh, it’s less than five times smaller than a CR2032, but its familiar 20mm diameter, 3.2mm thickness footprint made PCB design much easier than it would have been with other conventional lithium-polymer batteries.

With no prior experience with rechargeable batteries, we were taking a huge risk here with TM8. We studied numerous reference designs on the internet, and found some solid ones with good documentation that allowed us to make our own reliable power supply circuit. Using a 3.3v LDO voltage regulator, a Li-Po battery charger IC, and a P-channel MOSFET, our team created a rock-solid power supply with seamless switching between the battery and external USB power. Coupled with the MAX17048 fuel gauge IC, TM8 is well optimized for low-power operation.

PCB Design: PCB designer Eric Min

With the battery taking over a quarter of available space on the back of the watch, PCB space was incredibly tight, and our team worked for months optimizing the routing to find space. We are happy to report we’ve successfully implemented all our design goals within our target spec: 2 layers with traces no thicker than 8 mils. Our target spec was chosen so to minimize cost, as any tighter tolerances would’ve dramatically increased manufacturing costs. At one point we even had an IR receiver on the watch, but we removed it after a team meeting concluded it was too niche to be a legitimately useful feature. Instead, we replaced it with test pads for easier hardware debugging, should the need arise. Even without an IR receiver, TM8 is still the most complex, dense circuit we’ve ever designed. In fact, you can see components forming an arc right above where the battery sits, giving it just enough clearance to fit on the watch. Every nook and cranny was utilized, and we left no space on the watch unoccupied.

To route such a dense PCB, our team used 0402 size parts for the first time ever and reduced via size to 0.3mm. We also used SMD packages such as LGA and QFN for the first time. Using such footprints dramatically increased available board space. Time Machine Mk. 8 gave us numerous opportunities to try out new technologies, giving us valuable experience to build upon them in future projects.

While the top side wasn’t as complex as the bottom, it was a challenge on its own. To achieve a clean look on the top, our team worked hard to hide all vias under components to not disturb the gorgeous red soldermask and electroless nickel immersion gold finish. We did expose a few vias on the silkscreen lightning bolt, as we figured that was an exception where the vias actually added to the aesthetics. However, due to the extremely dense nature of the PCB, we wouldn't have been able to hide them even if we wanted to.

SHORTCOMINGS

SHORTCOMINGS, LIMITATIONS, AND FLAWS: Chief Technical Officer Eric Min

While we at Min Works are extremely proud of ourselves for realizing such an ambitious project, it is not without its flaws. As of now, the battery only lasts for a measly four hours on a single charge, and we have not been able to get the temperature and motion sensors working with the SAMD21. The RGB LEDs underneath the LCDs do not work on some colors, and the SPI Flash IC does not seem to be working as well. However, we are quite sure these are all software issues and we believe we can work these out slowly and steadily, one by one.

Eric Min

Eric Min