Project of 3rd year of engineering school

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Pièce principales bras.stlStandard Tesselated Geometry - 419.81 kB - 06/27/2023 at 12:27 |

|

|

Axe et maintien du support.stlStandard Tesselated Geometry - 200.77 kB - 06/27/2023 at 12:27 |

|

|

Support.stlStandard Tesselated Geometry - 69.71 kB - 06/27/2023 at 12:27 |

|

|

Motor control program.txtplain - 1.49 kB - 06/27/2023 at 10:35 |

|

|

Robotic Arm detailled project.pdfAdobe Portable Document Format - 789.95 kB - 06/26/2023 at 22:48 |

|

|

Once we'd finished programming the motors, we started looking at how our robotic arm would be guided. We started with an interface that would be on our mobile phone.

This page has been coded in html.

Once our various parts had been printed and assembled, we started to work on the programming part of our system, so that we could operate the motors using programs that we entered on the arduino board.

This part took longer than the others because the engine was struggling to work the way we wanted it to and, above all, to respect the different characteristics we had chosen.

You will find the right programme on our file !

We then started printing our various parts. We had a few problems with the dimensions of our main parts, which were too big for our printer, so we had to make our parts 30% smaller.

We also had a problem with the support because we'd forgotten to reduce its size, which meant that the part was too big and couldn't be assembled with the main parts of the arm. So we had to print it again, this time to the correct size.

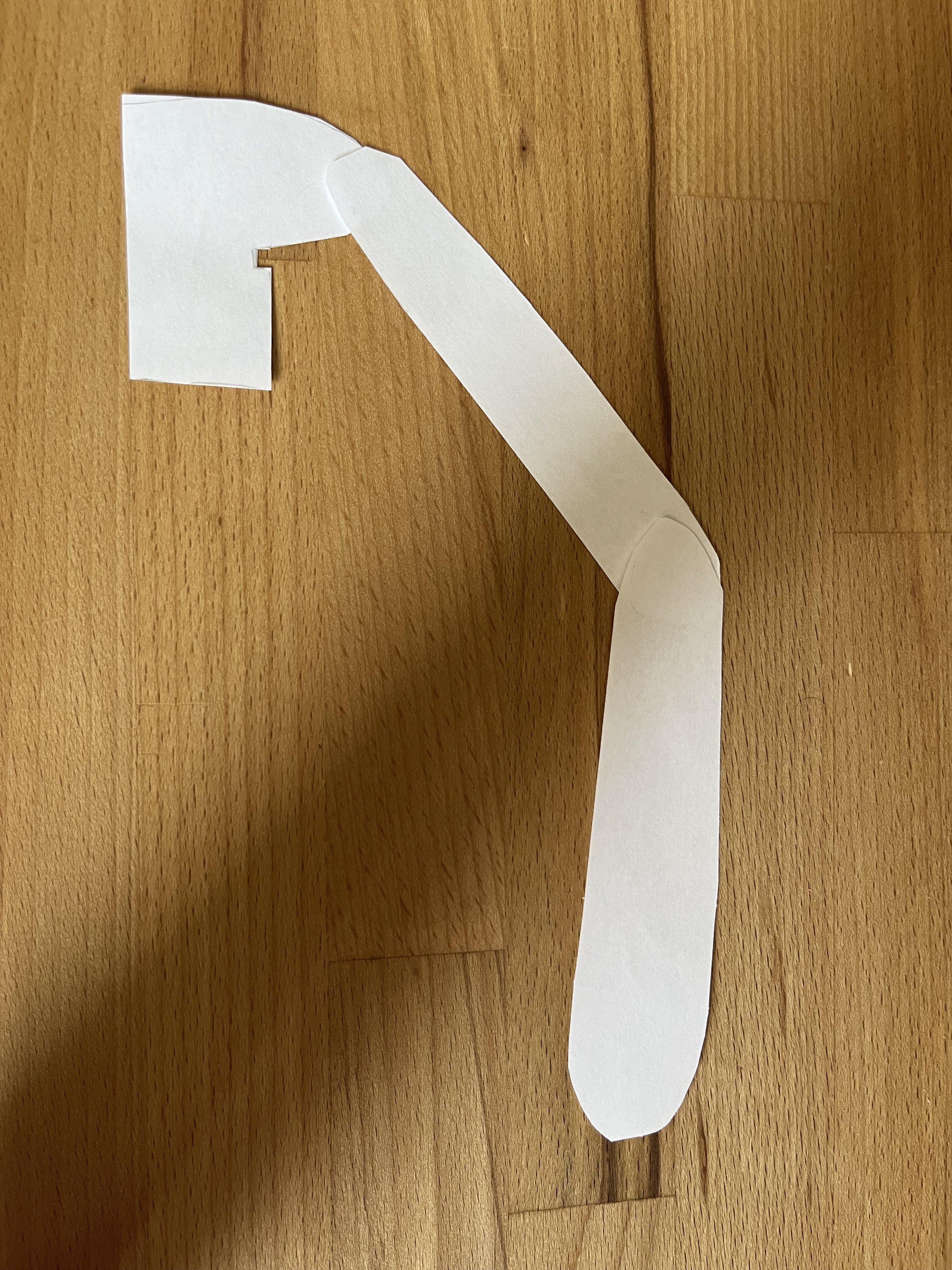

Once the first two parts have been assembled, we got this :

During our printing process, we also had to deal with the breakage of our support.

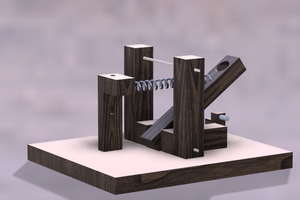

We then thought about the other parts that would make up our arm, such as the support and the axes. This was an important stage, because with the choice of our components, we had to add the space available for the components to fit in and make sure that it could function.

Once we had analysed the various problems we could face, we had to choose the components that would go with our robotic arm, which are :

1. Servomotors: We need a servomotor to provide the movement of the arm. For our project, a standard medium-sized servo motor will be sufficient.

2. Mechanical arm: For the mechanical arm itself, we can use carbon rods or aluminum rods to build the structure. there are several options available in the market that are suitable for our project, such as the SunFounder mechanical arm kit. But we decided to go through the 3D printer.

3. Control card: A control card is needed to manage the movement of the arm. The Arduino Uno board is a great option for this.

4. Cables: We need cables to connect the servo to the control board. You can use 30cm servo cables.

5. Power supply: A power supply is required to power the control board and the servo motor. So, a 9V battery or a 5V power supply.

6. Connectors: We will also need connectors to connect the various components together.

You will find the referencee of each components in the components list.

Having started directly with the design, we had no visual of the various problems we might encounter, so we created a card board which consisted of putting our parts in 2D on a sheet of paper. This enabled us to identify several problems such as :

- the number of freedom degre

- the angle of heel

We began by designing the plans for our arm using 360° fusion.

This is the main part of the arm, and is made up of two identical parts, assembled one inside the other.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

By using our website and services, you expressly agree to the placement of our performance, functionality, and advertising cookies. Learn More

ekaggrat singh kalsi

ekaggrat singh kalsi

Emily

Emily

Andy

Andy