This week wen by flying and unfortunately I had very little time to work on this project. I hope I can use the Sunday to do most of the modelling, printing and testing. At least the critical components and fits.

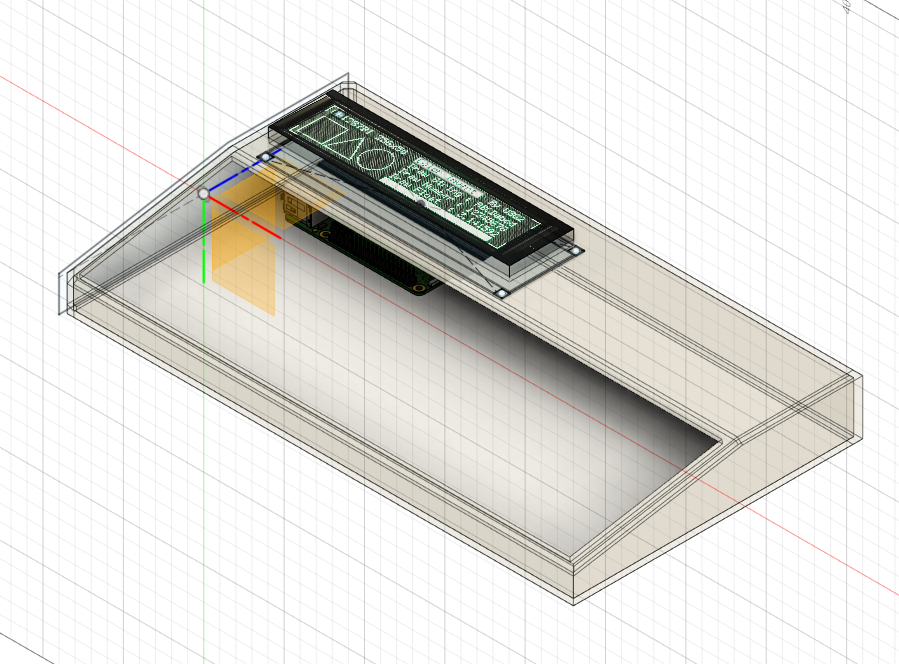

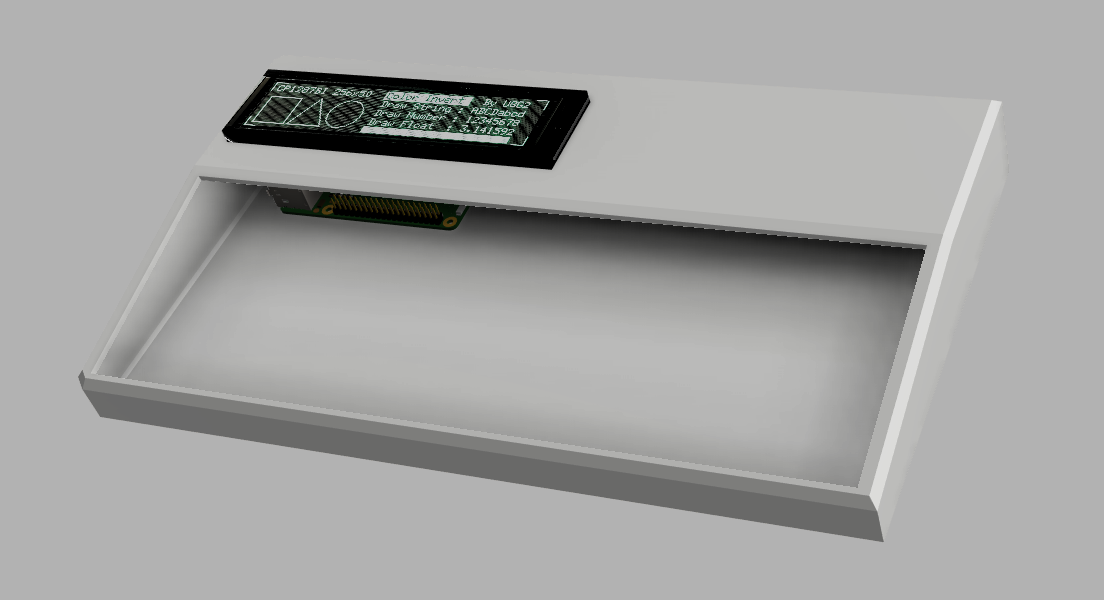

This is basically the second time (first project here) I'm modelling something using Fusion, so I'm still learning and looking for videos and tutorials as I go and that takes a lot of time.

I don't want this to look boring at all, so my idea is to print a basic shape with the display, raspberry pi and keyboard in the correct positions. After that I plan to add lots of detailing via panels screwed into the main body. That way I can quickly prototype these panels without having to print the most time consuming parts of the shell.

The challenge here is to design while having the orientation that everything is going to be printed. That also means that I have to think about how to split the body so that:

- It fits in my printer and I can prototype parts of the main shell without having to print the whole shape. For example, the raspberry pi fitting.

- So that some features like screw posts are not printed sideways (and mid-air) and thus have better resistance.

RobsonCouto

RobsonCouto

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.