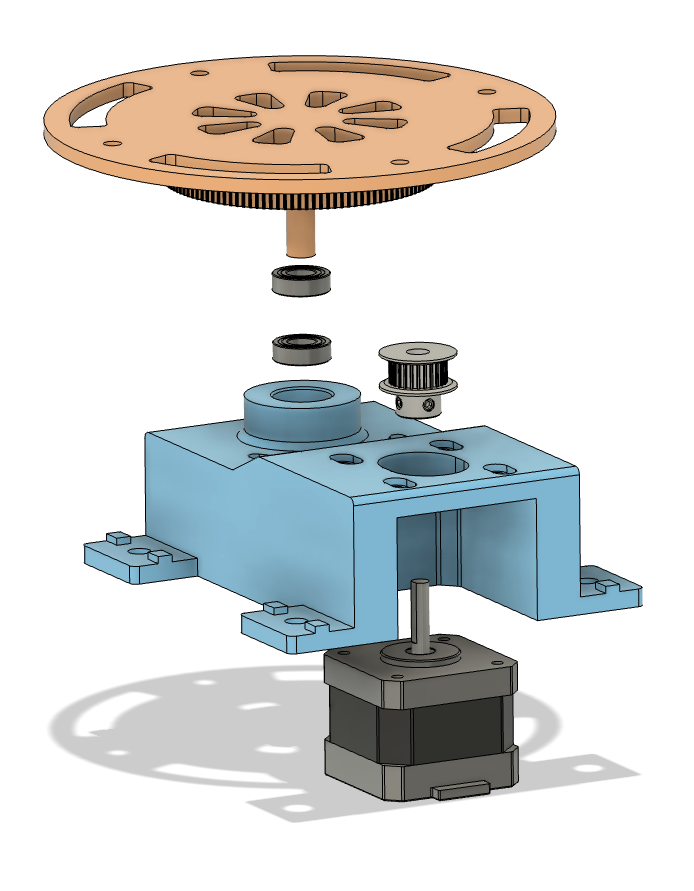

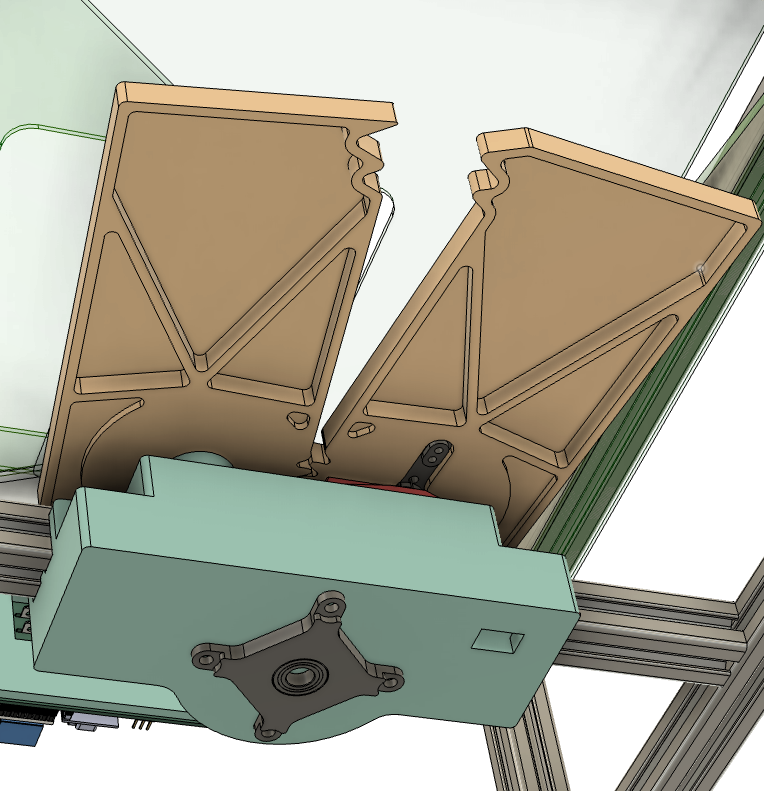

Just like the PCB and codes, all the 3D files are available in the "Files" section both as the .STL file ready to be 3D printed and also as the Fusion 360 project files, so you can modify or add more stuff from my design based on what you need.

This log will focus on discussing some of the design decisions that I've made and some manufacturing techniques that I've used throughout this build.

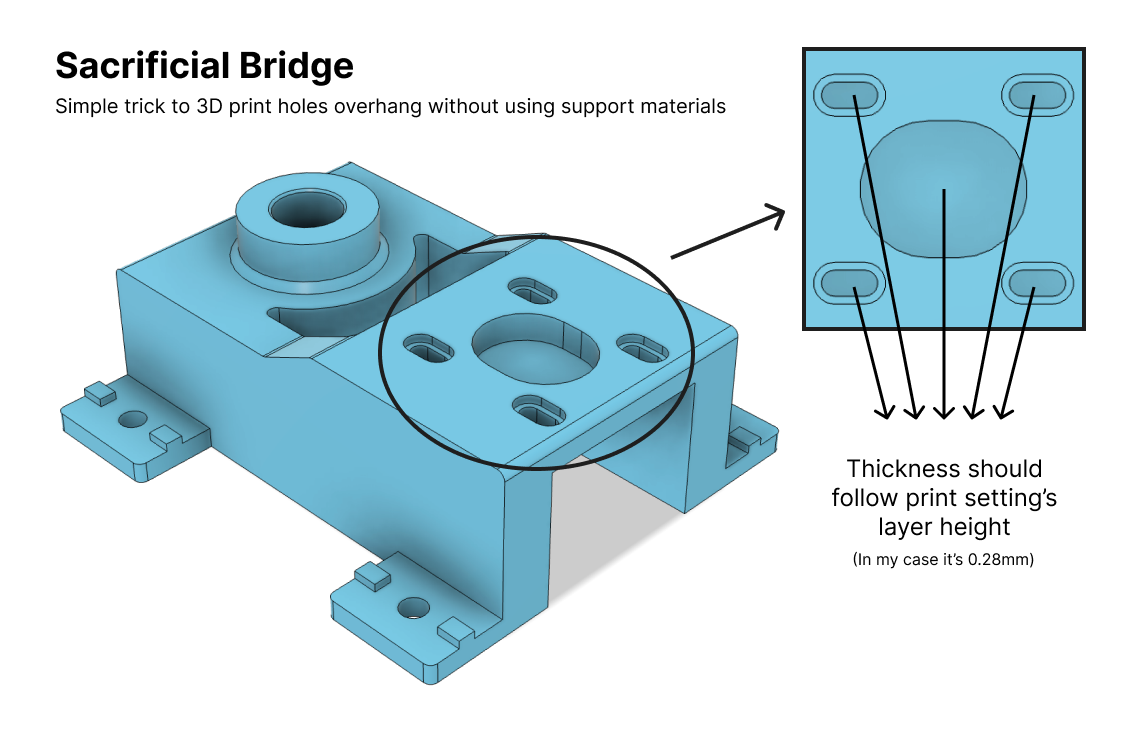

By simply adding one layer of extrusion, we can complete the print without any support materials, this is called sacrificial bridge. After finished printing, the "bridge" can be trimmed using scissors or cutting pliers.

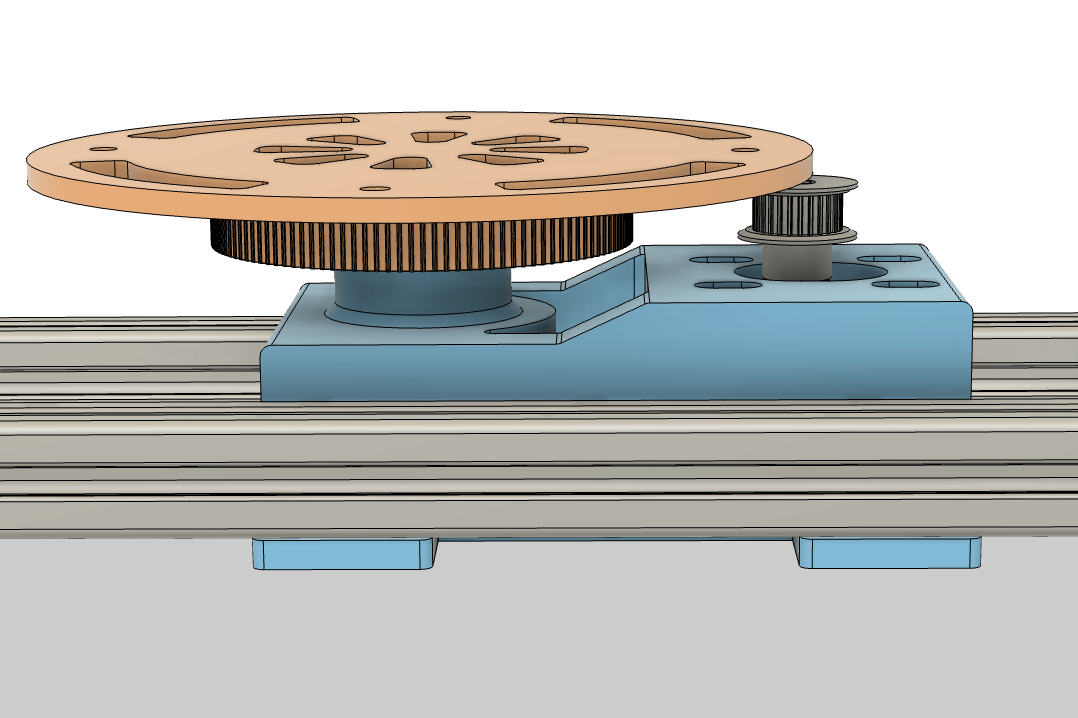

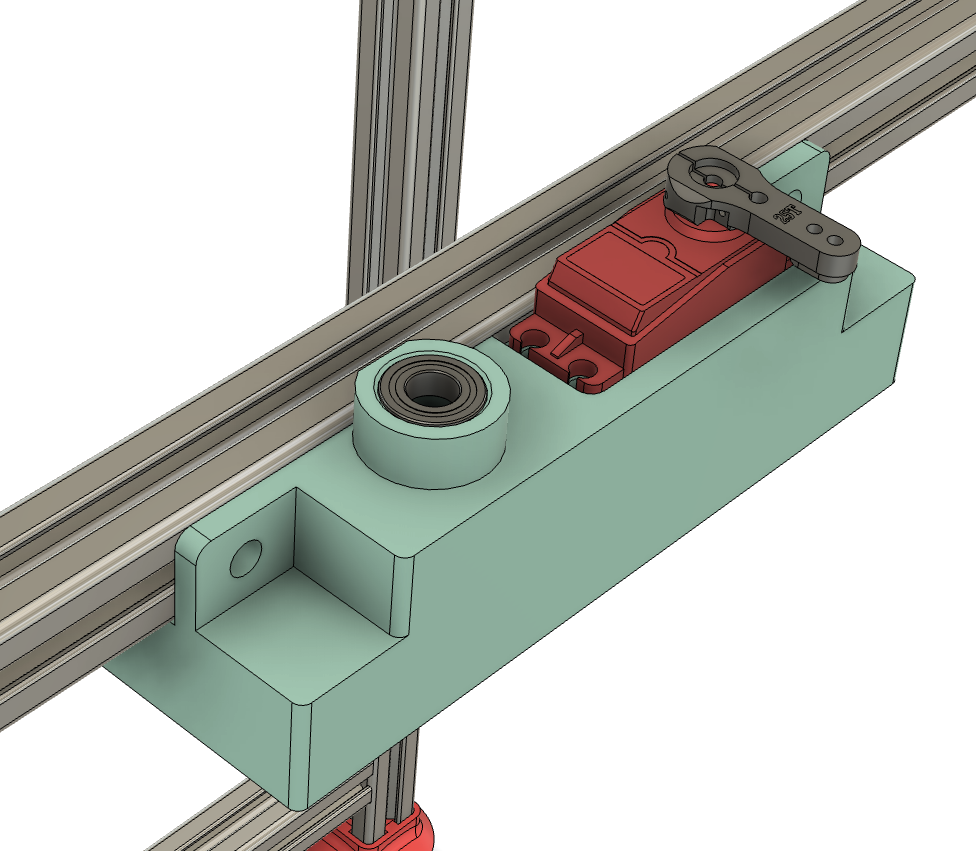

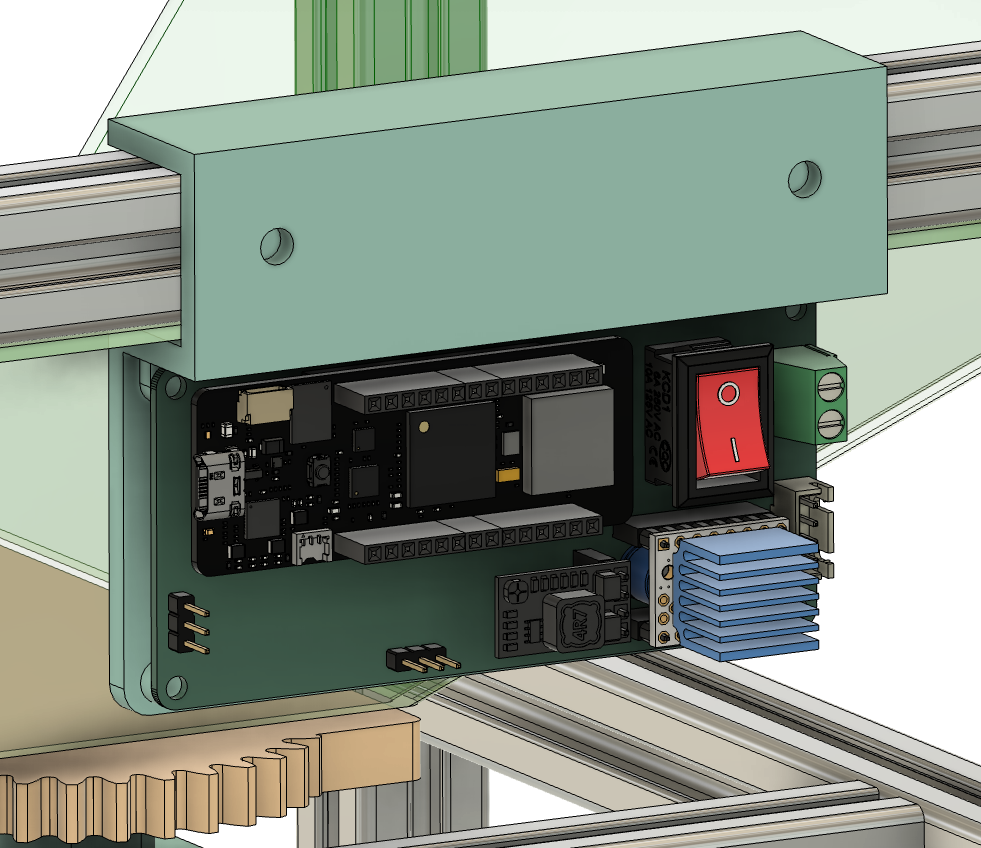

All of the 3D printed parts are mounted to the aluminium extrusion frame using M5 bolt and T-Nut.

The PCB design from KiCAD can be exported as a .STEP file which can be imported to the Fusion 360 project file. This will make it easier to create the mounting plate to the aluminium extrusion frame.

Samuel Alexander

Samuel Alexander

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.